How the Dober Lab Tests to Exceed Expectations

Testing, testing, testing: that is Dober's calling card in the performance fluids space.

Innovation might sometimes begin with a single "eureka" moment, but it can only progress with consistent testing. Furthermore, in our industry, consistent testing is the main way to ensure quality and customer satisfaction.

What that means is you need the necessary equipment to carry out the testing and a team with the technical know-how to operate testing apparatus, in addition to logging and interpreting data.

- Various testing standards and customer preferences Dober has to address

- Dober's global footprint

- Some of Dober's testing methods in the performance fluids space

Testing to Meet — and exceed — Requirements worldwide

Dober sells performance fluids around the world, meaning having to meet and, in many cases, exceed a wide variety of regulations.

For example, Dober is:

- Compliant with EU REACH, the primary set of regulations governing the manufacture and import of chemicals for Europe

- Certified under ISO 9001:2015, the international standard that specifies requirements for a quality management system (QMS)

- A member of the National Association of Chemical Distributors (NACD) and winner of the 2019 NACD Responsible Distribution Excellence Award

In addition to regulations and/or specifications from governmental and non-governmental (e.g., ASTM) organizations, Dober also deals with varying preferences by region (or even from customer to customer).

Our product line contains different additive packages to meet each region’s unique specification for coolant chemistry. Whether you operate in Asia and prefer a “BANS”-free (i.e., borate, amines, nitrite and silicate) solution or operate in Europe and prefer a “NAPs”-free (i.e., nitrite, amines and phosphate) solution, Dober offers an additive package that works with a particular regional preference.

Dober also boasts eight blending locations around the world, including North America, South America, Europe and Asia.

.png?width=600&height=338&name=8%20Coolant%20Additive%20Blending%20locations%20(1).png)

Meanwhile, Dober is an ASTM Committee 15 member, meaning we are at the forefront of testing standardization in the space. As we've noted elsewhere, standards for fuel cell and battery electric vehicle testing have not been finalized by ASTM yet; as such, Dober will be ready to work with the new standards when they are ready. (Update: Since the publication of this article, ASTM published new test standards for electric vehicle coolants.)

As for Dober's engine audit fluid, we test all our products to ensure they pass the most stringent standards. For example, D17-MX was formulated to pass not only ASTM-D3306 standards, but also many engine manufacturers' standards.

Bottom line, Dober operates in a global environment. That means we have to address a wide range of regulations that vary from region to region, in addition to meeting and exceeding customer- or region-specific requirements. That second part is particularly true in the performance fluids space, and especially for the battery electric and fuel cell vehicle coolants market, for which established testing standards have not been finalized. As such, different companies are going out into the market with their own specifications, whether for electrical conductivity or any other of a great number of metrics one can find on a typical technical data sheet.

Dober Testing

As mentioned, Dober has a wide range of testing processes in the performance fluids space. Below, we'll briefly review some of them:

Modified ASTM D1384 Glassware Corrosion Test

ASTM D1384 outlines the standards for the traditional corrosion test for engine coolants in glassware. Metal coupons are submerged in a coolant solution over a prescribed period of time and temperature, after which they are assessed both by weight (i.e., weight gain or loss) and visually for marks, discolorations, etc.

However, the traditional ASTM D1384 glassware corrosion test featured the metals of copper, solder, brass, steel, cast iron and cast aluminum. For next-generation coolants — those for use in battery electric or fuel cell vehicles — the test is modified to feature the metals more common in those systems.

As such, the modified D1384 glassware corrosion test Dober uses features copper, brass, 304L stainless steel, 316L stainless steel, 5052 aluminum and 6061 aluminum.

Below you'll find coupons from a modified D1384 glassware corrosion test comparing Dober's Fuel Cell Ultra Low Conductivity (FC ULC) coolant with that of a competitor. The table below indicates weight gain and weight loss for each metal (a positive number indicates weight loss, while a negative indicates weight gain).

ASTM D1384 is just one standard to which Dober adheres. Other relevant ASTM standards for which Dober tests across its product lines include:

If you're interested in learning more about Dober's D1384 testing, we were recently published in Lubes'n'Greases magazine ("Testing the Coolants of Tomorrow").

Copper Wire Test

The copper wire test is a relatively simple, but important, test of a coolant.

In summary, copper wire is dipped into a coolant solution; if a deposit develops on the wire, that means the coolant has failed the test. Why? The development of a precipitate on the wire means the potential disruption of electric current. You can see an example of such a deposit in the image to the right.

In a world where testing standards for the next generation of vehicles haven't been defined just yet, the copper wire test is one quick way to test and compare coolants.

The copper wire test, which typically takes about 20 minutes, is conducted as such:

- Remove the rubber cover of the copper wire (spreading the wires out like a fan)

- Dip the wires in coolant solution to be tested

- Apply 15 V and 10 A for 20 minutes

- Check for formation of deposit on wire

If the coolant is highly conductive, then the current will flow through the wires, turning them blue. If the coolant is extremely conductive, however, a deposit will form on the wires, which is not what you want to see.

If the coolant is not particularly conductive, then you will see the wires appear unchanged. Furthermore, the coolant solution itself should also be free of precipitate.

Unlike, say, the ASTM D1384 test, which features hard limits for corrosion weight loss, the copper wire test is a visual test without an established rating scale. You can see examples below of what failing and passing copper wire tests look like.

Forced-Air Ovens

Compatibility is another crucial facet of your performance fluid.

What does that mean, exactly?

In simple terms, your coolant must be compatible with the various materials and components within an engine. Metals, elastomers/polymers and other materials in the engine should not deteriorate or experience excessive corrosion after consistent contact with the coolant over time. Such issues could lead to a decline in performance of the vehicle, added costs associated with repairs and even operational safety concerns.

Dober's testing capabilities include multiple forced-air ovens, pictured at right, which serve as an initial indicator of compatibility (or incompatibility).

To test for compatibility, a material is placed in a coolant solution in a beaker. The beaker is then placed in the forced-air oven to be tested for a period of time (typically determined by the customer's request). The forced-air oven is then set to reach a particular temperature to simulate operational conditions (e.g., 80 degrees Celsius). Air circulates throughout the oven to produce a uniform temperature environment.

Following conclusion of the test period, the material is then evaluated for any potential effects, like swelling, discoloration or even disintegration. If the material has fallen apart, then it is not compatible.

Dober also utilizes third-party testing to confirm test results, providing an added layer of testing to the process.

Through this process, Dober has developed an ever-growing portfolio of compatibility testing data. If you are interested in finding out if a particular material of yours is compatible with our coolants, reach out to us and we'd be happy to check your material against our database.

Parr Reactor Test

In addition, you must test coolants over time and temperature. In other words, you need to mimic real-world conditions.

The Parr reactor test is another tool for assessing changes in pH and electrical conductivity over time. The test conditions used are as below:

- Temperature: 150°C (302°F)

- Pre-charge of air: 90 PSI

- 10 feet copper wire

- Duration: 2 weeks

- Sample withdrawal intervals: 7,14, and 20 days

- Measurement parameters: pH, conductivity, and color change

These parameters were considered since earlier authors (Yu-Sen Chen et al., Comparison of bench test methods to evaluate heavy duty coolant thermal stability, Journal of Testing and Evaluation, May 2006, ASTM) from Dober and Cummins Fleetguard developed this method to model primarily the thermal stability of heavy-duty coolants in 300,000-400,000 miles of actual service.

The takeaway is that initial pH or electrical conductivity cannot be the primary determining factor in the efficacy of the coolant. One coolant might begin with seemingly more favorable pH or electrical conductivity readings, but might experience a more significant changes in those data points over time than another coolant.

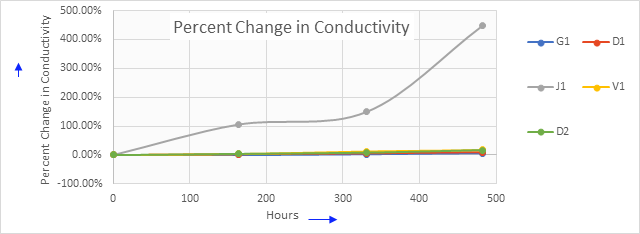

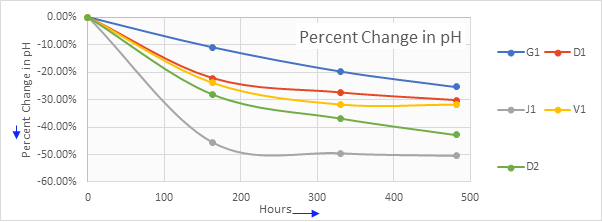

Take the examples below. The Dober team conducted the Parr reactor test using five different coolant solutions. As Figures 1 and 2 show, the coolant solutions exhibited varying trajectories over time vis-à-vis electrical conductivity and pH, with the coolant coded J1 showing the most significant percent changes.

Figure 1: Percent change in conductivity

Figure 2: Percent change in pH

Deionizer Test

Another important factor to consider in your coolant: you don't want your vehicle's filtration system to strip important corrosion-inhibiting additives from the coolant. Without the necessary additives in the coolant, the system is vulnerable to corrosion.

As such, Dober has designed its own deionizer test method, in which coolant is pushed through a simulated fuel cell system, including a filter, to assess additive depletion rate over time. Furthermore, the team continues to run long-term trials to assess the impact of different types of ion exchange filters on additive supply within various coolants.

Dober Testing Summary

In short, the Dober laboratory team leverages a wide variety of tools to test its performance fluids products and drive innovation.

At Dober, testing is the lifeblood of innovation and consistent quality. Particularly in the rapidly evolving battery electric and fuel cell vehicle spaces, the team continues to investigate novel ways to test.

Interesting in learning more about our testing capabilities in the performance fluids space? Reach out to us and we'd be happy to chat.

-1.png?width=352&name=PFD%20-%20Product%20Page%20-EV%20SLC%20(2)-1.png)

.png?width=352&name=PFD%20-%20Product%20Page%20-EV%20SLC%20(2).png)