Why Electric Vehicle Coolants Are Failing Basic Corrosion Tests

The beauty of the bacon, lettuce and tomato (BLT) sandwich is the simplicity of it. You have just three core ingredients, and if you use high-quality bacon, crisp lettuce and a fresh tomato, you’ve set yourself up for a tasty lunch. And while the addition of mayonnaise or an egg will help take this lunch to the next level, your BLT is incomplete without bread.

In a similar vein, an engine coolant is usually referred to as a 50/50 or 70/30 mix of just two ingredients: water and glycol.

Yet, an engine coolant is utterly incomplete without a third ingredient: the corrosion inhibitor package.

Each component plays a critical role in the coolant:

- Water – excellent heat transfer properties to remove heat from the engine

- Glycol – provides freeze protection by increasing the freeze point of the liquid

- Corrosion inhibitor package – provides corrosion protection to the metals, gaskets and fittings

The evolution from inorganic to organic acid technology (OAT) marked the last major innovation of corrosion inhibitor packages. Now, let’s explore how new-energy vehicles are driving the newest string of innovations for corrosion inhibitor packages.

Corrosion inhibitors for electric, fuel cell and other new-energy vehicles

There are two reasons corrosion inhibitor packages built for the internal combustion engine need to evolve for new-energy vehicles:

- Metals used in electric and fuel-cell vehicles are different than metals used in the internal combustion engine

- Low electrical conductivity is now a required specification from many OEMs to maintain a safe environment.

ASTM Committee D15 is responsible for developing all the testing and specification standards for engine coolants. It is prudent to take the time necessary to set high standards with great care and thoughtfulness of the future.

Yet the speed at which commercialization is happening in the market has outpaced development of new standards. (Update: In 2023, ASTM published new test standards for electric vehicle coolants.)

This has created a short window in which manufacturers claim their products are designed for EV or fuel cell vehicles, but those products fall short in basic corrosion tests.

Testing corrosion inhibitor packages for new-energy vehicles

Current EV and fuel-cell vehicles are cooled via an indirect cooling system whereby the coolant travels through an enclosed loop rather than coming in direct contact with the battery or fuel cell stack. This method of indirect cooling is the same as the cooling system in an internal combustion engine.

Therefore, the corrosion testing methods will likely be very similar, with adjustments to the metals and temperatures used in the testing.

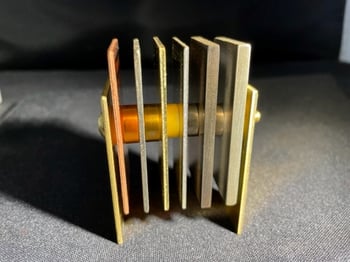

The method of testing corrosion protection of coolants starts by assembling a corrosion test bundle. The test bundle represents the different metals that must be protected within the engine. Since the metals used in EVs and FCVs are much different than those used in the internal combustion engine, a coolant test bundle for EV or fuel cell coolants will more likely resemble the one pictured below, which includes copper, solder, brass, steel, cast iron and cast aluminum.

The next step is to follow the D1384 test method to measure corrosion of the test method. A typical D1384 rig looks much like the rig in Dober’s Performance Fluids Lab shown in the image below.

The test method for a heavy-duty combustion engine is as follows:

ASTM D1384 is a simple glassware corrosion test that can be used to evaluate the corrosion inhibition properties of a coolant on various metal specimens. The metal specimens used are those that are typically found in an engine cooling system (copper, solder, brass, steel, cast iron and cast aluminum).

So how does the test work?

- These metal specimens are arranged in bundles and immersed in a coolant test solution.

- The coolant test solution is prepared using corrosive water (sodium sulphate, sodium chloride and sodium bicarbonate).

- The coolant solution is heated to 88°C for a period of 336 hours. The coolant solution is also aerated.

- After the test period, the metal specimens are removed from the coolant solution, after which they are cleaned, dried and weighed.

- The inhibition performance of the coolant is evaluated based on the weight changes on each of the specimens. Negative values indicate weight gain, while a positive value indicates weight loss.

Results of D1384 Testing for Fuel Cell Coolants

In the results below, we are evaluating the weight loss/weight gain of each metal compared to current ASTM limits. Each coolant tested claims to be made for electric or fuel-cell vehicles.

|

Coolant |

Dober FC Coolant ULC |

European Competitor |

NP-Competitor |

ASTM D1384 Limits MAX, mg |

|

Copper |

-1.58 |

0.77 |

37.17 |

10 |

|

Solder |

8.15 |

26.60 |

170.15 |

30 |

|

Brass |

-0.23 |

2.47 |

98.62 |

10 |

|

Steel |

144.83 |

807.53 |

7437.38 |

10 |

|

Cast Iron |

163.77 |

1050.77 |

5110.12 |

10 |

|

Cast Aluminum |

-4.27 |

1.73 |

109.13 |

30 |

The highlighted cells are samples that failed corrosion testing for a particular metal.

How could this be that coolants developed for use in EV or FC vehicles are failing basic tests?

We suspect there are three main reasons:

- Meeting the electrical conductivity requirement of new-energy vehicle OEMs requires major step-change innovation in the coolant industry. In the absence of updated ASTM testing methods for new-energy vehicles, coolant manufacturers could meet the electrical conductivity spec while sacrificing the protection of metals.

- In the absence of a standard test method, companies are using many variations of ASTM D1384. For example, one could use low test temperatures (60-80°C) or avoid corrosive water and air flow. You will typically not find these details in the technical data sheet of BEV/FC coolant manufacturers. When selecting a coolant, ensure it has been tested under various real-life conditions to give robust corrosion protection built in the formula.

- The metals used in new-energy vehicles are different than those we all have been accustomed to protecting in the internal combustion engine. For example, there are different grades of aluminum used in electric vehicles. A traditional ASTM test would not test these various aluminums.

Failing a corrosion test is unacceptable in the world of the internal combustion engine. We know it will soon be unacceptable in the world of new-energy vehicles.

We also know the coolant industry is filled with passionate students of the industry who will rise to the challenge.

At Dober, we develop coolants with corrosion inhibitor packages that protect electric and fuel cell vehicles so that you can focus on making the vehicles that are changing our world. If you’d like to learn more about the testing or try our sample, drop us a line and we’d love to talk.