Dober Coolants Offer Superior Corrosion Protection of EV, FC Metals

The cooling system for an internal combustion engine (ICE) vehicle is a well-understood system. Coolant flows through a radiator, absorbing heat from the internal combustion engine and releasing it to the air to keep the engine cool.

Metal materials of construction for these types of cooling systems are well known and well studied. For a coolant to be a practical consumer product, it must provide corrosion protection for metals such as copper, solder, brass, mild steel, cast iron and cast aluminum, as detailed in the ASTM Standard Test Method for Corrosion Test for Engine Coolants in Glassware (D1384).

Dober has a great deal of knowledge when it comes to protection of these internal combustion engines, whether through inhibitor syrups for conventional coolants, hybrid organic acid coolants or organic acid coolants.

But what about electric vehicle (EV) and fuel-cell (FC) vehicle cooling systems?

corrosion protection for Electric Vehicles, Fuel-Cell Vehicles

Electric vehicles and fuel-cell vehicles are relative newcomers to the market space. Because they are so new, there are no established standards for metal protection like there are for internal combustion engine cooling systems. (Update: Since the publication of this article, ASTM published new test standards for electric vehicle coolants.)

Further complicating the matter, different parts of the world could be using varied materials of construction, particularly when it comes to aluminum alloys. For instance, what is used in the United States might be a different grade of aluminum alloy than what is used in Asia, which might be a different grade of aluminum alloy than what is used in Europe.

As such, electric vehicle cooling system protection can be an incredibly challenging enterprise.

Using its knowledge in formulating inhibitor syrups for internal combustion engines, Dober has quickly become a leader in electric vehicle cooling system protection.

Which metals will Dober’s EV fluids protect? Dober has employed various methods to show how well its EV fluids perform when it comes to protecting cooling systems, using either Dober EV Coolant SLC (Super Low Conductivity) or Dober FC Coolant ULC (Ultra Low Conductivity) when compared against some leading competitor coolants.

Traditional ASTM D1384 Glassware Corrosion Test

Traditional ICE metals (copper, solder, brass, steel, cast iron and cast aluminum 319) were studied in this test. Dober EV Coolant SLC and Dober FC Coolant ULC were compared against two competitor coolants that are currently marketed for use with electric or fuel-cell vehicles.

Test results are shown below. Negative numbers denote a weight gain. Positive numbers denote a weight loss.

|

Coolant |

Dober EV Coolant SLC |

Dober FC Coolant ULC |

European Competitor |

NP-Competitor |

ASTM D1384 Limits MAX, mg |

|

Copper |

-0.18 |

-1.58 |

0.77 |

37.17 |

10 |

|

Solder |

17.00 |

8.15 |

26.60 |

170.15 |

30 |

|

Brass |

2.07 |

-0.23 |

2.47 |

98.62 |

10 |

|

Steel |

-0.42 |

144.83 |

807.53 |

7437.38 |

10 |

|

Cast Iron |

4.57 |

163.77 |

1050.77 |

5110.12 |

10 |

|

Cast Aluminum 319 |

184.28 |

-4.27 |

1.73 |

109.13 |

30 |

While Dober FC Coolant ULC did fail on steel and cast iron against established ASTM corrosion weight loss limits for these metals, the degree of failure was far less than the degree of failure of the European competitor as well as an NP competitor.

In fact, on all other metals, Dober FC Coolant ULC had less corrosion weight loss than either of the competitor coolants. Dober EV Coolant SLC failed on cast aluminum, with a value a bit higher than the NP competitor. However, SLC was as good as, if not better, at corrosion protection on all other metals compared to the two competitor coolants.

This test shows that Dober FC Coolant ULC will protect the traditional ICE metals of copper, solder, brass, steel, cast iron and cast aluminum and Dober EV Coolant SLC will protect copper, solder, brass, steel and cast iron better than leading competitors in the EV market space.

Modified ASTM D1384 Glassware Corrosion Testing

While the traditional ASTM D1384 test has shown that Dober EV Coolant SLC and Dober FC Coolant ULC have superior corrosion protection than both competitor coolants when it comes to protection of copper, solder, brass, steel, and cast iron, and ULC has superior corrosion protection when it comes to cast aluminum, there are other metal alloys that are being used in electric vehicles and fuel-cell vehicles.

The solder, steel and cast iron from the traditional ICE ASTM D1384 isn’t prevalent in an electric vehicle or fuel-cell vehicle cooling system. Instead of the mild steel found in ICE engines, stainless steel can be present in an electric vehicle or fuel-cell vehicle.

A bigger difference in metal alloys comes to play when talking about aluminum alloys. The aluminum alloys used in the U.S. aren’t necessarily the same alloys that are used in Europe, which in turn aren’t necessarily the same as alloys used in Asia. Even within in Asia, research has shown there can even be differences in aluminum alloys from country to country.

Since there are no established standards to rely on for evaluation of electric vehicle and fuel-cell vehicle corrosion protection, Dober uses a modified ASTM D1384 Glassware Corrosion Test to compare quantitatively (corrosion weight loss) and qualitatively (the physical appearance of the metal specimens) metal specimen protection between Dober EV Coolant SLC, Dober FC Coolant ULC and competitor coolants.

Three modified tests were developed to study the various metals that could be found in an EV or FC vehicle: one to study copper, brass and stainless steel, as well as other aluminum alloys from the U.S.; a second to study stainless steel alloys, as well as aluminum alloys obtained from Korea; and a third to study copper and stainless steel alloys with aluminum alloys obtained from China.

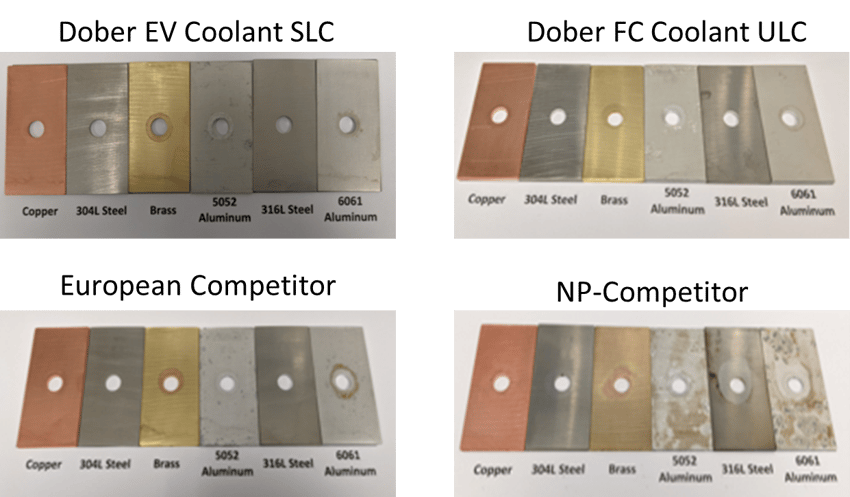

The first test studied copper, brass, 304L and 316L stainless steel, and aluminum alloys of 5052 and 6061.

Corrosion data from this test is shown below. Negative numbers denote a weight gain. Positive numbers denote a weight loss.

|

Coolant |

Dober EV Coolant SLC |

Dober FC Coolant ULC |

European Competitor |

NP-Competitor |

|

Copper |

-1.23 |

-1.53 |

-0.83 |

2.97 |

|

304L Steel |

-1.47 |

-0.77 |

-1.07 |

-0.72 |

|

Brass |

-0.03 |

0.22 |

0.62 |

32.42 |

|

5052 Aluminum |

45.73 |

63.98 |

33.28 |

148.43 |

|

316L Steel |

-1.17 |

-0.57 |

-0.52 |

-1.57 |

|

6061 Aluminum |

-3.92 |

-3.72 |

-3.62 |

63.98 |

Corrosion weight loss data shows that Dober EV Coolant SLC and Dober FC Coolant ULC protected the metals studied comparatively well to the European competitor and protected the metals studied better than the NP competitor.

A better indication of the protection can be seen in a visual comparison of the metals after the test. The picture below shows the metal specimens after the test visually looked better from the Dober EV Coolant SLC and Dober FC Coolant ULC than either of the two competitor coolants.

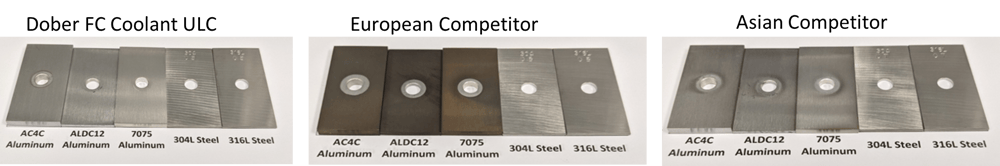

The second test studied 304L and 316L stainless steel along with aluminum alloys of AC4C, ALDC12 and 7075 from Korea. We compared Dober FC Coolant ULC to the same European competitor, in addition to an Asian Competitor.

Corrosion data from this test is shown below. Negative numbers denote a weight gain.

|

Coolant |

Dober FC Coolant ULC |

European Competitor |

Asian Competitor |

|

AC4C Aluminum |

-3.47 |

-2.87 |

-4.07 |

|

ALDC12 Aluminum |

-3.67 |

-3.07 |

-3.57 |

|

7075 Aluminum |

-3.37 |

-2.87 |

-3.37 |

|

304L Steel |

-1.37 |

-0.77 |

-1.17 |

|

316L Steel |

-1.07 |

-1.07 |

-0.67 |

Corrosion weight loss data showed that Dober FC Coolant ULC was comparable in corrosion protection to competitor products from Europe and Asia on all metal types.

Where Dober FC Coolant ULC really stood out is when the metals are inspected visually. While the European competitor and Asian competitor specimens experienced a large amount of discoloration, especially on the aluminum alloys, there was little to no discoloration in the Dober FC Coolant ULC specimens.

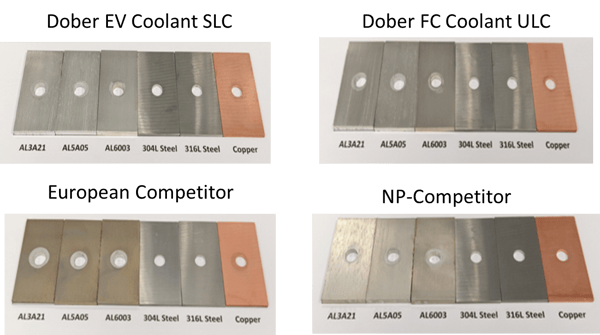

The third test studied 304L and 316L stainless steel, along with aluminum alloys of AL3A21, AL5A05, AL6003 from China. Dober EV Coolant SLC and Dober FC Coolant ULC were compared to the same European competitor coolant as above, as well as the previously mentioned NP competitor.

Corrosion data from this test is shown below. Negative numbers denote a weight gain. Positive numbers denote a weight loss.

|

Coolant |

Dober EV Coolant SLC |

Dober FC Coolant ULC |

European Competitor |

NP-Competitor |

|

AL3A21 Aluminum |

-3.67 |

-3.97 |

-2.37 |

-2.22 |

|

AL5A05 Aluminum |

-3.82 |

-3.61 |

-2.27 |

-2.07 |

|

AL6003 Aluminum |

-4.07 |

-3.32 |

-2.62 |

-1.92 |

|

304L Steel |

-1.37 |

-1.32 |

-1.47 |

-1.37 |

|

316L Steel |

-1.32 |

-1.22 |

-1.07 |

-1.22 |

|

Copper |

-1.73 |

-1.63 |

0.07 |

7.47 |

Corrosion weight loss results for this test showed comparable weight loss data in the Dober EV Coolant SLC and Dober FC Coolant ULC to the weight loss data from the European competitor and NP competitor, except for copper. The European competitor and NP competitor showed weight losses in copper specimens, while the Dober FC Coolant ULC did not. This copper data corroborates the previously shown results in the traditional ASTM D1384 testing.

When visually inspecting the metal specimens, Dober EV Coolant SLC and Dober FC Coolant ULC displayed a better physical appearance after the test than the European competitor and a similar appearance to the NP competitor. The European competitor and NP competitor showed a larger degree of discoloration, especially in aluminum, than either of the Dober products.

Using traditional ASTM D1384 testing — as well as modified versions of the test to allow for incorporation of various other metals that could be present in an electric vehicle or fuel-cell vehicle — Dober has been able to demonstrate corrosion protection as good as, if not better than, leading competitor products when it comes to all metals tested.

Want to learn more about our EV SLC coolant? Visit our EV SLC page for additional information.

.png?width=352&name=PFD%20-%20Product%20Page%20-EV%20SLC%20(2).png)