What Type of Coolant Does My EV Need?

Electric vehicles, fuel-cell vehicles and other new-energy vehicles of the future require coolants of the future.

In our recent articles, we’ve touched on a range of topics related to electric vehicles and electric vehicle coolants (in addition to fuel-cell vehicles). We’ve touched on:

Whether you have an electric vehicle or fuel-cell vehicle already or maybe you’re in the market for one, you’ll want to be informed about the type of coolant that should be going into your vehicle.

With that said, what do you need to know about electric vehicle and fuel-cell vehicle coolants? Let’s recap some things you should know when considering an electric vehicle and/or fuel-cell vehicle coolant. You can also download our battery-electric vehicle and fuel cell vehicle coolant e-books for more information.

Vehicle coolant Electrical Conductivity Matters

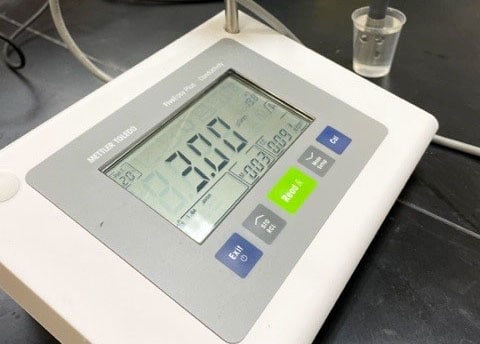

As we previously discussed, electrical conductivity is at the heart of the electric vehicle coolant and fuel-cell vehicle coolant discussion — Dober’s electric vehicle coolant product is called EV SLC (Super Low Conductivity) for a reason.

To recap, electrical conductivity is a different ballgame in electric vehicles relative to internal combustion engines (ICE). Coolants used for ICE vehicles could have a much higher range of conductivity, ranging from 3,000-5,000 microsiemens per centimeter µS/cm.

However, electrical conductivity is a much bigger concern for EVs and fuel-cell vehicles. Operation safety and efficiency for battery-electric vehicles (BEV) and fuel-cell vehicles are controlled by stable and low electrical conductivity.

The coolant subsystem in high-voltage fuel-cell stacks (above about 50 V) can, however, present an electrical shock hazard. If the coolant is sufficiently conductive and is in electrical contact with and interconnects parts of the fuel-cell stack that are at different potentials, the coolant fluid can pose a safety problem. Furthermore, the coolant also provides a path for the flow of undesirable corrosion currents. A conductivity of less than about 50 µS/cm is recommended by BEV OEMs, while FC OEMs have indicated an ideal value of <5µS/cm. (Update: Since the publication of this article, the Chinese government published a new GB standard, GB29743.2, covering electric vehicle coolants. The new standard includes an electrical conductivity specification of less than 100 microsiemens per centimeter. In early 2025, Dober's EV-LC coolant received a passing result under the new standard's testing protocol.)

As with many things in the new-energy vehicle space, there aren’t uniform standards just yet. (Update: Since the publication of this article, ASTM published new test standards for electric vehicle coolants.) But we do know that most new-energy vehicles today are using coolants designed for ICE vehicles.

But for safety and performance, you want a coolant formulated specifically for your EV or fuel-cell vehicle.

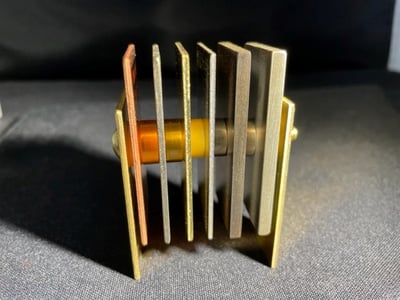

Corrosion Inhibition Packages Must Protect EV Parts, Materials

Another way new-energy vehicles diverge from the old guard is materials. Corrosion inhibition, however, remains every bit as important.

If you’re an EV or fuel-cell vehicle owner, you want a coolant that offers a robust corrosion inhibitor package.

While the corrosion inhibitor package represents a sliver of the coolant’s makeup — water and glycol making up the overwhelming majority of it — it punches far above its weight in terms of importance.

New-energy vehicles have different metals and other materials that require protection.

Dober’s D1384 testing assesses corrosion over time by measuring weight loss in a coupon bundle consisting of a range of metals (copper, solder, brass, steel, cast iron and cast aluminum).

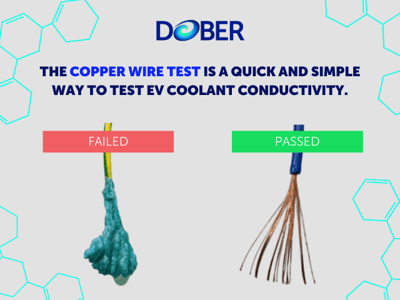

Copper Wire Test

As we talk about the differences between ICE and new-energy vehicles – and, in turn, the coolants that go into them – we should again highlight the various testing methods Dober employs.

Testing standards are in the process of being developed for new-energy vehicle coolants. Technological developments have outpaced the rate of standardization.

What does that mean? Nonstandard tests will have to fill in that gap between standardization and development.

One example is the copper wire test, which Dober uses to test conductivity. A copper wire is placed in a beaker of coolant solution and subjected to certain conditions (15 V for 20 minutes).

Upon completion of the testing period, we check for the formation of a deposit on the wire. If the wire turns blue or, even further, a deposit develops on the wire, that indicates the coolant is excessively conductive.

What does that mean? Again, an increased risk of electrical fire.

What you want to see is the picture on the right of the passing test, showing an essentially unchanged copper wire.

Lower-conductivity coolant makes the possibility of an electrical fire in the vehicle less likely.

Electric Vehicle Coolant Compatibility

Finally, we come to the question we hear all the time: Is part or material X or Y in my company’s model compatible with your coolant?

In other words, will the coolant work well with the constituent parts of the vehicle's system?

In addition to conductivity and corrosion inhibition, compatibility is the third of the Big Cs when it comes to electric vehicle and fuel-cell coolants.

The theme continues: next-generation vehicles are different than their gas-powered predecessors. Different power sources, different engines, different materials.

Complicating things further, OEMs entering the new-energy vehicle space are using a wider range of parts and materials.

How do you know if they’re compatible?

Dober has a growing portfolio of material compatibility testing data with our EV SLC coolant. With both in-house testing — like in our forced-air ovens pictured at right — and third-party verified results, companies can get data about the compatibility of their parts, whether it’s a rubber, plastic, metal or something else.

Dober has been innovative and ahead of the curve in recognizing that next-generation vehicles require next-generation coolants. While testing standards have yet to be solidified, Dober has been forward-thinking in its development of a coolant formulated specifically for EVs.

Most new-energy vehicles on the road today are using coolants designed for ICE vehicles.

But it doesn’t have to be that way.

With the principles of electrical conductivity, corrosion inhibition and compatibility in mind, Dober’s EV SLC coolant has been produced specifically with EVs in mind.

If you’d like to learn more about our EV SLC coolant, visit our dedicated page.