Would you ever dip a carrot in mayonnaise? Probably not.

How about pouring a coolant designed for an internal combustion engine into a vehicle powered by fuel cells? Yeah, not a good idea.

But with all the amazing engineering advancements that have helped fuel cell technology become a reality, the coolants used in these vehicles have seemed to be an afterthought.

This shouldn’t be a surprise, though, because history has a way of repeating itself.

When Henry Ford rolled out the Model T, he would soon learn that he would need more than water to effectively cool and protect his engines. Fuel cell vehicle manufacturers and after-market support networks will soon learn that traditional coolants won't cut it and they will have new needs that coolant manufacturers will need to meet. This article outlines some of the key requirements that will be different in fuel cell coolants from the coolants we know today.

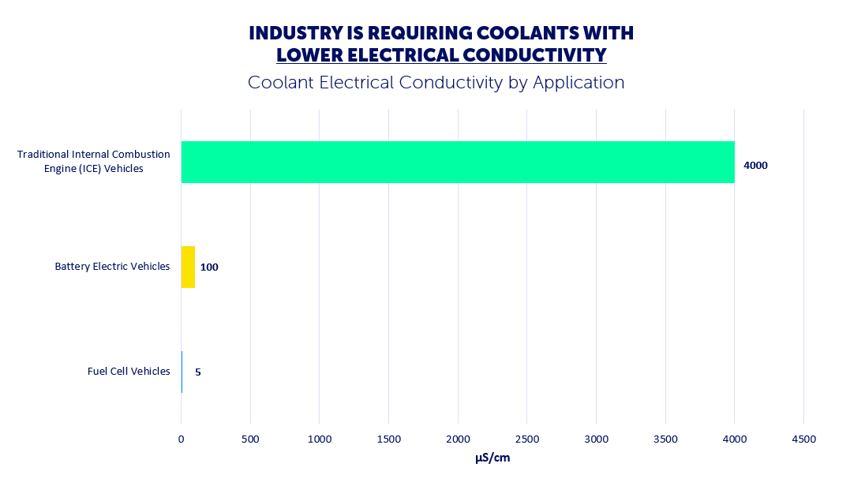

The main difference from internal combustion engine coolants that we’re seeing today is the requirement for lower electrical conductivity. Traditional coolants have electrical conductivity of 2,000-4,000 μS/cm while fuel cell vehicles may require electrical conductivity to be as close to zero as possible (see Table 1.0, "Coolant Electrical Conductivity Requirements").

Measuring electrical conductivity at room temperature under no stress will be just the starting point. As the vehicle operates, the coolant will need to maintain a low electrical conductivity over time and temperature. Failure to do so would lead to increased maintenance costs because of the reduced longevity of deionizer filters while potentially increasing the safety risks of the fluids in the vehicle.

Table 1.0: Electrical Conductivity Requirements of Fuel Cell Coolants

Aluminum, already common in diesel engines, will be even more prevalent in electric and fuel cell vehicles. Aluminum is lighter than iron and steel, so increasing the amount of aluminum will help reduce the weight of the vehicle. This helps the vehicles achieve longer ranges between recharges.

But not all aluminum is created equal.

Anyone building these vehicles is aware of the different grades of aluminum. One must ensure that the coolants have corrosion inhibitor packages capable of protecting the grades of aluminum in your vehicle. We had to develop some new formulations to ensure these aluminum grades were protected, and our competitive research has shown that many coolants fail to protect some of these aluminum grades.

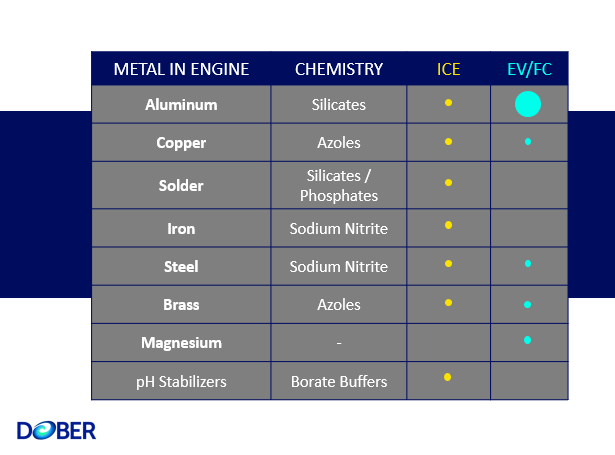

While we add more aluminum, it is time to say goodbye iron and goodbye solder. It was nice knowing you, but we won’t be needing your services in fuel cell vehicles. Without these metals in the engine, there will not be the need for certain corrosion inhibitors in the coolants. And although having them in the formula won’t cause any harm to these new vehicles, they aren’t required and would add unnecessary costs to the coolants.

The table below provides a snapshot of how different metals will require different corrosion packages. While this provides a general representation of what we are seeing in the market, there will be many fuel cell manufacturers that will use different metals in different ratios, so be sure to evaluate each coolant with the individual OEM specifications.

Table 2.0: Metal Corrosion Inhibitor Packages for EV/FC Engines

As the commercialization of fuel cell vehicles ramps up, we expect to see different specifications for coolants. This will require coolant manufacturers to lean on their institutional knowledge to be nimble and custom formulate for OEMs. Over time, the industry will develop testing methods that are more appropriate than copying methods from ICE engines. We expect industry specifications to become more aligned over time and we will help develop ASTM guidelines that meet the demands of fuel cell vehicles. (Update: In 2023 ASTM published new test standards for electric vehicle coolants.)

Dober has been protecting engines with coolant technology for almost 40 years, but never before have we seen such an industry-changing shift like the one we're seeing today. It is hard to keep up with the news as companies such as Cummins and Hyundai are making the hydrogen economy a reality. Although we may fall behind on our Twitter newsfeed, we will remain at the forefront of providing sustainable fuel cell coolants to the industry. Remember, no one wants to dip their carrot in mayonnaise!