Lesson 1: Industrial Cleaning Is Critical

In this course, "Intro to Formulated Detergents," we'll walk you through some foundational elements to think about when considering cleaning in various industrial and/or manufacturing settings.

Whether you're looking to improve your facility's cleaning processes, have a pretty good process already but just want to learn more or you need to devote more intentional thinking to cleaning, we hope these reading materials will help you on your way.

In this first module, we'll start with the basics: why is industrial cleaning critical?

The answer might seem obvious, but it isn't always so, as not every operation is proactive about industrial cleaning.

Why is Cleaning Critical? Everyone NEEDS to Do It

When we think about cleaning at home, for example, even the most consistent among us has a lazy day here or there. Sometimes, we might push off doing the dishes, folding the laundry or picking up toys strewn about in children's play areas.

If you've done that — and given how busy our lives are, who hasn't at some point? — then you've probably noticed that the repercussions were minimal. You might experience a little added stress from the messy environment or, worst case, might have the misfortune of stepping on a Lego or two from time to time ... but in the end it isn't a huge deal.

However, in various industrial and/or manufacturing settings, that is not the case. If you're a pharmaceutical manufacturer, for example, you have to clean on a regular, consistent basis with a consistent process and effective, efficient cleaning products.

A few bullet points to remember:

- Everyone has to clean. Cleaning is a critical part of every operation, particularly those producing products that will be consumed orally or delivered via other methods (topical products, ophthalmics, etc.).

- Operators in these industries must insure they clean their process equipment efficiently to prevent both cross-contamination and microbial contamination in subsequent batches.

- Cleaning is a regulatory requirement, and is an important part in achieving a validated state for manufacturing. (Among other services, Dober's Chematic team offers validation support.) You can read more about cleaning regulations in the Code of Federal Regulations (Title 21, Chapter 1, Subchapter C, Part 211, Subpart D), which states:

Equipment and utensils shall be cleaned, maintained, and, as appropriate for the nature of the drug, sanitized and/or sterilized at appropriate intervals to prevent malfunctions or contamination that would alter the safety, identity, strength, quality, or purity of the drug product beyond the official or other established requirements.

Five key traits of a Quality industrial Cleaning Program

When you walk into any space, whether it's a home, a business or some other place, it can often be easy to tell when the owner takes pride in cleaning. Things are put away in an organized and systematic fashion, surfaces are clean and shiny, and there might even be a nice scent to the place.

What is less obvious on the surface is the cleaning process that gets to that final clean result.

So, what are the elements of a quality cleaning program?

A quality cleaning program features:

- A repeatable cleaning process

- A reputable cleaning agent (designed for your specific manufacturing process)

- Safety — handling by your people, the environment, etc.

- Efficiency — more internal message, cost avoidance, labor savings

- Consistency — meets consumer expectations

when it comes to cleaning, knowledge is the ultimate detergent

Cleaning is an intentional process: you'll get out of it what you put into it.

If you clean without understanding what you're trying to clean, what you're cleaning with and how you're trying to do it, you won't get optimal results.

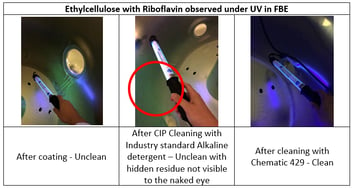

- Every industry has its challenging residues. Trying to clean these products without a good understanding of the residue, and the proper chemistry to address them, can lead to increased cleaning time, higher labor costs, and higher usage of water and cleaning agents.

- An inefficient cleaning process uses more cleaning materials, increases equipment downtime resulting in more time spent on cleaning than on making product.

- Using the correct formulated detergent and cleaning process to target tough-to-clean residues helps pharmaceutical companies achieve their manufacturing goals.

- The aim is to keep the operation running efficiently with decreased downtime, less cleaning material waste and increased safety.

So, How Do You Improve your cleaning program?

Truth be told, improving your cleaning program is relatively simple. The most important thing is having the intention to do it.

- Be proactive about cleaning. Don't make it an afterthought.

- Make sure you're using the right cleaning products.

- Teach your employees proper cleaning procedures and make sure they stick to them with consistency.

Cleaning doesn't have to be difficult. However, it does take some work upfront to identify if your process is really working as it should and, if not, determining the best course of action toward improving your program. It's better to start with a proactive mindset regarding cleaning, rather than a reactive one that could force you to take corrective measures that will cost you time and money.

This concludes the the first installment of this course, "Intro to Formulated Detergents." Continue on to Lesson 2 to learn more about benefits associated with implementing a quality cleaning process.