pharmaceutical CLEANING

validated cleaning processes with chematic cleaners

active pharmaceutical ingredients & excipient cleaning

Pharmaceutical cleaning with FORMULATED DETERGENTS FOR CLEANING PHARMACEUTICAL MANUFACTURING EQUIPMENT

Pharmaceutical cleaning validation is paramount to the success of the overall pharmaceutical manufacturing process. In fact, while process engineers typically view pharmaceutical equipment cleaning as a final step, we view it as the first.

We specialize in the manufacturing of cleaning agents for the regulated and critical cleaning industries such as pharmaceutical manufacturing. In addition to the targeted cleaning enabled through the use of our formulated detergents, we provide an optimized cleaning process that is customized for each client’s products and equipment.

Our pharmaceutical detergents meet cGMP standards and offer a thorough and repeatable cleaning process to achieve cleaning validation of pharmaceutical equipment.

solid dosage

liquid / orals

opthalmic

suppositories

Inhalation

parenteral

topical

ENT

PROPER pharmaceutical CLEANing STARTS HERE

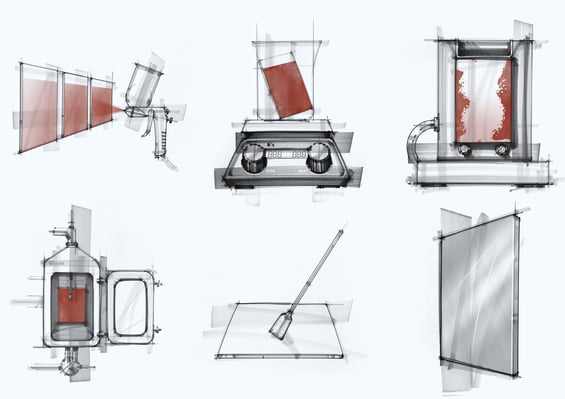

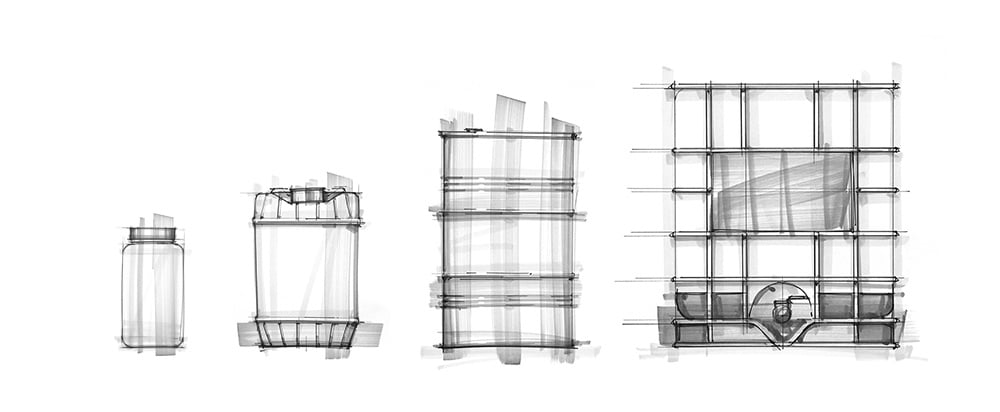

Our formulated detergents and customized cleaning recommendations are integral to a proper Custom Cleaning Evaluation (CCE). As a result of the CCE study, our cleaning recommendations help clients develop an effective cleaning validation protocol. This allows customers to meet their market demands by improving throughput and turnaround time with efficient cleaning, which is specific to their products, equipment, and regulatory requirements.

Want to know what is the best cleaning recommendation for your residue? We're here to help.

Pharmaceutical Cleaning Chemicals

We deliver commercial cleaning solutions that are founded on a strong commitment to lasting relationships that solve our customers' day-to-day challenges. Our mission is to use our applied research and development innovations in chemistry and technology to deliver value-added solutions to our customers.

Simultaneously, we provide insights regarding proper application cleaning methodologies for the benefit of regulated markets. Cleaning agents used in the pharmaceutical industry must facilitate cleaning validation and meet strict criteria for effectiveness. Working together with our clients, we specialize in achieving these goals.

improved pharmaceuticaL cleaning progrAM BENEFITS

Maximize use of Assets

Non-optimized cleaning solutions/processes typically waste precious time that could otherwise be devoted to production. Our products and processes have been repeatedly proven to cut downtime and maximize efficiency — resulting in consistent, effective cleaning and reliable validation.

Increased Production Capacity

Inefficient and/or ineffective cleaning can affect your bottom line by interfering with production capacity. Working closely with your process engineers, our professionals will choose the optimal pharmaceutical cleaning solution and devise the optimal cleaning process for your specific application. Working together, we will help you minimize downtime and maximize production capacity.

Improved Operator Safety

By improving your approach to choosing the right cleaning agent for your pharmaceutical process(es), we can help you maximize production while simultaneously minimizing operator exposure to potentially harmful substances. Our detergents are selected according to your needs, which helps slash time spent on equipment cleaning. Often, our carefully engineered detergents allow you to achieve optimal cleaning not only faster, but while using lower water temperatures — that also boosts safety.

Reduce Cleaning Time

Our optimized solutions help you spend less time on cleaning, freeing more time for active production. Reduced cleaning time also means less time expended on costly labor. Both of these advantages can improve your bottom line.

Reduced Contamination Risks

By improving cleaning from start to finish, you will experience a potentially significant reduction in contamination risks.

Eliminates the Need to Re-Clean

Re-cleaning is inefficient, time-consuming, and costly. Our carefully engineered detergents — and processes — help you achieve cleaning validation quickly and consistently. In some instances, clients have been able to shift away from manual scrubbing, while realizing superior results. Manual scrubbing may damage equipment and make future pharmaceutical cleaning validation more difficult to achieve.

chematic® can help with your cleaning process development

read on

WHY THE EXISTENCE OF A 'UNIVERSAL CLEANER' IS A MYTH

While the majority of the residues can be cleaned with one cleaner, some require special chemistries for efficient cleaning. Learn why.

9 VARIABLES FOR SELECTING AN IDEAL PHARMACEUTICAL CLEANING AGENT

Learn about nine variables to consider when choosing the right cleaning agent for your equipment and residue.

TOP 5 INDUSTRIAL CLEANING MISTAKES AND HOW TO AVOID THEM

Ever wondered why your pharmaceutical cleaning is inefficient? Or why you have to reclean after performing a validated cleaning process? Here's why.