The Optimal Cleaning Process for Your Equipment

Our custom cleaning evaluations start with a simulation of your cleaning process to optimize and target the residues you are trying to clean. These custom studies deliver effective physical and chemical cleaning recommendations that:

- Improve cleaning safety

- Meet your manufacturing and compliance goals

- Eliminate the need to re-clean

- Create an efficient cleaning process for increased asset utilization

Chematic Provides a Complete Cleaning Solution for Your Production

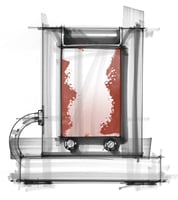

Your Process Replicated

Cleaning processes can be as unique as you are. This is why we take time to understand your process and replicate every aspect to provide you with the best cleaning solution.

Chemistry Selection

A quick look at solubility of your soil allows for the detergent selection process. Then through coupon-beaker studies, a best -fit cleaner for your process is selected.

Process Optimization

After a detergent has been selected, your cleaning process is optimized for ideal detergent concentration and temperature based on your cleaning capabilities.

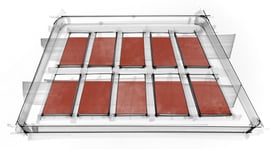

Scaling Up

To verify the optimal solution has been found, we take our cleaning evaluations a step farther. We have the capability to scale-up from the lab to our in-house production size CIP system.

Validation

Validating a new cleaning detergent can be quite the undertaking. We are able to provide all required documentation and validated test methods for our detergents, making us an extension of your analytical team.

On-Site Support

Our technical experts provide assistance during your cleaning trials and assist you with any pre-trial, post-trial questions.

Optimal cleaning process? Check.

Now let's get you validated.

During cleaning validation there can be many hurdles to overcome like developing new HPLC & TOC analytical methods. Chematic® is committed to providing you with any cleaning validation consultation, assistance, or implementation that you need through our Analytical Technical Transfer Package.