Video: Manufacturing Cleaning in Action

In the pharmaceutical, nutraceutical, cosmetics, and personal care manufacturing industries, cleaning is far more than a routine maintenance task: it is a cornerstone of product integrity, consumer safety, and regulatory compliance.

An effective cleaning process in these environments is foundational, like a lower-level piece of a Jenga tower. When you pull it out, there's a good chance the whole thing is going to topple over. Cleaning in manufacturing environments is just that important.

And while there's a regimented, prescriptive structure on cleaning processes in these environments, that doesn't mean they can't be enjoyable. In fact, for professionals in these industries, there can come a great satisfaction with an effective clean of a piece of equipment.

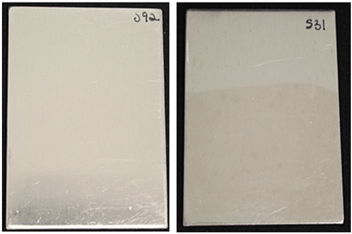

If you're one of those people, check out our latest video from the Dober Chematic lab showcasing our cleaning products in action:

Why is Cleaning Important in Manufacturing Environments?

These industries handle complex formulations and sensitive ingredients that can leave behind residues capable of contaminating subsequent batches if not properly removed. In pharmaceuticals, even trace amounts of cross-contamination can compromise drug efficacy or cause adverse reactions, putting patient health at risk.

Similarly, in the nutraceutical and personal care sectors, leftover actives, oils, or preservatives can impact product stability and performance, leading to costly recalls or damage to brand reputation.

What Are Some Important Manufacturing Cleaning Guidelines?

Strict regulations in this space include those outlined by:

- the FDA

- the EMA

- cGMP guidelines

These mandate validated cleaning procedures to ensure repeatable and verifiable cleanliness. This is particularly vital in multipurpose facilities where equipment is used for different products.

Cleaning validation must demonstrate that procedures consistently remove residues to below acceptable levels, preventing cross-contamination and microbial risks.

What Are the Benefits of Effective Cleaning in Manufacturing Environments (Including Pharmaceutical, Nutraceutical and Cosmetics/Personal Care)?

Beyond compliance, effective cleaning supports operational efficiency.

Residue buildup can lead to:

- Equipment wear

- Production delays

- Higher maintenance costs

Investing in optimized cleaning methods, including chemistry tailored to specific soils and substrates, not only improves product safety but also enhances throughput and reduces downtime.

As consumer expectations for quality and transparency grow, manufacturers must go beyond meeting baseline requirements. Demonstrating proactive cleaning practices signals a commitment to excellence and builds trust with regulatory bodies and end users alike.

In this environment, robust cleaning programs — supported by well-equipped laboratories and expert guidance — are not optional. They are essential to delivering safe, effective, and high-quality products in highly competitive markets.

To learn more about Chematic products and see if there's a product for your application, download our product catalog by clicking the image below.

.jpg?width=352&name=Chematic_Containers_01%20(1).jpg)