How to Conduct Lab Scale Cleaning Trials

The regulations in the pharmaceutical industry are constantly being updated to include aspects of various processes that were considered unimportant before. Similarly, the pharmaceutical industry itself is trying to be one step ahead by implementing procedures that ensure maximum quality and efficiency of the final pharmaceutical product.

Cleaning of the product contact parts is one such aspect that was often neglected and age-old cleaning methods were used that led, not only to extensive usage of manpower for scrubbing, but also failures such as cross-contamination and microbial contamination due to incorrect cleaning practices. Because of this, the pharmaceutical industry turned to the sophisticated semi-automated and automated cleaning hoping that their cleaning issues would be taken care of, and although cleaning was improved, all the cleaning issues in the pharma industry were far from being sorted out.

The main reason for the Pharmaceutical industry struggling with unexpected cleaning issues is that little to no attention is paid to the science-based development of a cleaning procedure for a given product.

The solution to this is that cleaning development should start at the Formulation and Development stage. Along with product development, a scalable cleaning process should be a part of the technology transfer for each product. For existing products that are in commercial manufacturing already, a change of cleaning agent or process could be difficult due to the re-validation requirement but if there is a good return on investment by increased capacity and profits due to reduced downtime, it must be considered. Here, the paradox is that without making sure if the change in cleaning will be beneficial, the company wouldn’t want to invest in the development of analytical methods for the residual detergent analysis, without which, the cleaning agent cannot be introduced and tested in the production equipment. In this case, the cleaning process should be developed in the laboratory and scaled up before cleaning validation.

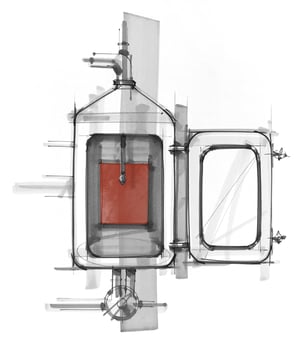

However, as F&D scientists are not expected to be experts in cleaning agents and the science of cleaning, they should work together with cleaning agent manufacturing companies to determine the right cleaner as well as the optimal cleaning conditions. Dober’s Chematic division provides support for cleaning procedure development by replicating the residue & cleaning conditions, that are available in the production site, in the Chematic lab and testing the cleaning agents. This decreases the time and effort of the pharmaceutical company and helps them get the starting guideline from which they can proceed with optimization in the laboratory before moving to scale-up.

The question that arises quite frequently during testing and optimization is ‘How to start?’.

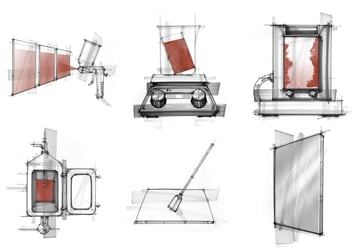

Listed in the document are a few guidelines to perform laboratory scale cleaning trials by considering scale-up, equipment, and parameters. Based on the equipment, residue, and method of cleaning, the laboratory trials have to be modified to suit individual cleaning processes.

It is always recommended to work with cleaning agent manufacturing companies to develop the most efficient cleaning procedure, cleaning scale-up, and troubleshooting.