ARE YOU AWARE OF THIS HIDDEN CHEMICAL HAZARD IN YOUR SCHOOL?

Schools everywhere, at every education level, face increasing numbers and types of safety and liability concerns. These include bullying and other forms of school violence, safe transit to and from school, students with food allergy issues, vaccination noncompliance, playground injury risks…the list goes on and on.

Could building maintenance activities put students and staff at risk?

School maintenance tasks themselves can present risks that may not be apparent—and may not even be on your radar. For example, when was the last time you gave any thought to the safety of your cooling tower water treatment chemicals? Treating the water in your cooling towers is necessary to prevent bacterial growth, as well as the buildup of scale, sludge and other unfavorable conditions. However, the liquid chemical additives traditionally used for this purpose can be dangerously caustic. Transporting buckets of these liquid chemicals through your facility also represents a spill hazard, along with the potential for injury to students and staff.

What’s lurking in your cooling towers?

Microbial organisms responsible for Legionnaire’s disease could be colonizing and contaminating your cooling systems. And you know that’s something you don’t want to mess around with. Regulations around testing and prevention may be spotty and inconsistent, but that doesn’t mean you can ignore the potential dangers. Over 25,000 cases of the illness are estimated to occur each year, causing more than 4,000 deaths1, with cooling towers thought to be a significant source.

Drifting droplets disseminate disease

Cooling towers operate using heat transfer dynamics, utilizing cooled water to absorb heat from the system. In the process, some water also escapes the system as fine moisture droplets in the cooling tower fan exhaust. This water loss is described as drift, and it is this drift that can carry disease organisms like Legionnella into the air, potentially infecting not only students and staff, but your neighbors as well.

Time for a safer, solid approach

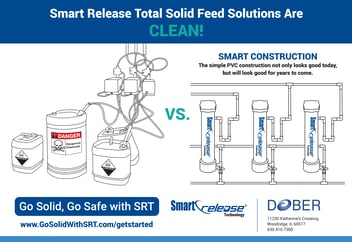

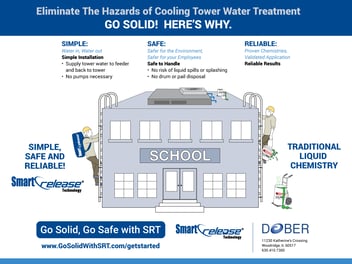

The most immediate hazard, however, involves the handling of liquid chemicals used to control microbial growth. That’s why newer, innovative treatments have been developed as dry solid chemicals that are safer to handle and safer for the environment—with non-hazardous inhibitor packaging, requiring no drum or pail disposal. Better still, they are also available in preconfigured system add-ons, with a small footprint, that automatically provide continuous treatment and control.

Dober, the innovator in cooling tower water treatment

“We take a holistic approach when developing our chemistries, to include delivery technologies that make them easier and safer to use,” explains Dennis Kelly, Cooling Tower Treatment Manager at Dober, and Chairman of the ASTM Committee on Industrial Heat Transfer Fluids, “especially for school settings where children could be injured.”

These innovative cooling tower treatment technologies—offered by Dober through water treatment specialists across the world—are currently being used to treat over 10,000 cooling towers at universities and other educational institutions, hospitals, data centers, commercial buildings, manufacturing facilities and many more. Dober, a leader in developing exceptional chemistry and brilliant technology is soulfully dedicated to safer solutions for our environment.

To learn more about how Dober’s cooling tower chemistries can help mitigate school safety risks, contact your water treatment specialist, or call Dober at 800-323-4983 for assistance locating a water treatment specialist near you.