COOLING TOWER FEEDER EQUIPMENT

LIQUID CONTROL,

SOLID DELIVERY

SRG2 gives you the control of a liquid with all the benefits of a solid.

Have the best of both worlds with the SRG2 platform, allowing you to have the control of a liquid program and all the benefits of solid delivery in your cooling tower water treatment system.

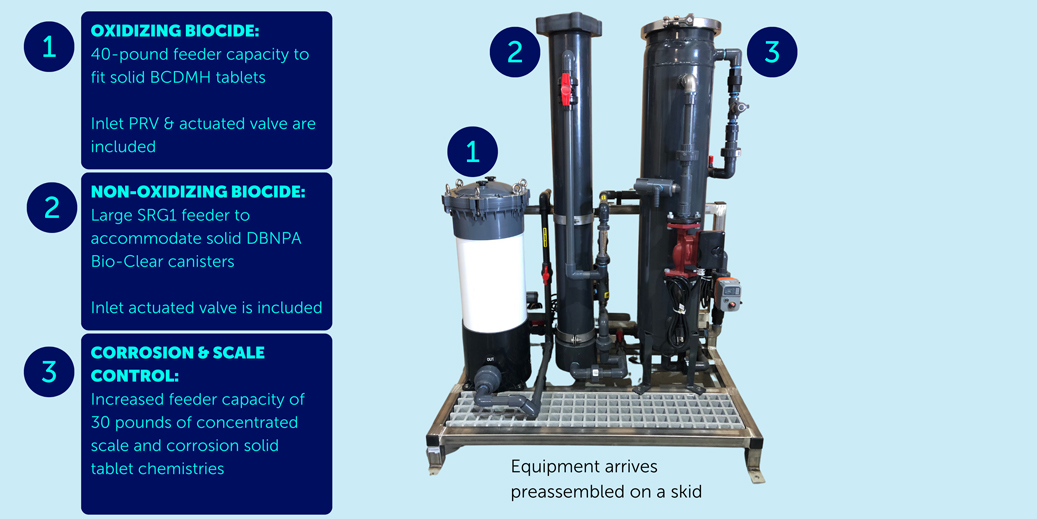

SRG2 cooling tower feeder equipment

SRG2r

Smart Release Generation 2r (SRG2r) builds on the same proven coated-tablet chemistry platform pioneered with SRG1.

By pairing tablet technology with smart sensor/controls integration, SRG2r enables precise, verifiable dosing, data-driven adjustments, and remote monitoring. The result is the consistency of SRG1 with the control, traceability, and optimization today’s programs demand.

SRG2e

Smart Release Generation 2e (SRG2e) systems come pre-fabricated on a stainless-steel frame or injection molded vessel stand that are easily movable by a pallet jack or a two-person team.

Each base is equipped with a control valve to allow for control of chemical feed to your cooling system as well as all recirculation equipment required for the exchange vessels.

SRG2sf

Smart Release Generation 2 Simple Feed (SRG2sf) delivers the proven Smart Release SRG2r approach with a simple, larger capacity package.

Like SRG2r, it releases the coated solid chemistry tablets in a recirculated holding tank. However, SRG2sf uses a non-pressurized, lid top tank along with a single combination recirculation/delivery pump to both circulate water through the tank and deliver treated solution to the system, reducing components and simplifying service.

Make sure you're protecting your cooling tower system and the people who make it run.

Download our Smart Release Generation 2 e-book to learn more about how you can optimize your system's performance and make your team's job easier.

when less is more

NO CHEMICAL METERING PUMPS NEEDED

Have peace of mind chemicals are being fed as intended, without the worry of common challenges with chemical metering pumps.

NO WORRIES ABOUT DRUM, PAIL DISPOSAL

We believe sustainability should be measured by what you do, not what you say. Smart Release technology can help.

Imagine This Footprint

CONTROLS LIKE A LIQUID

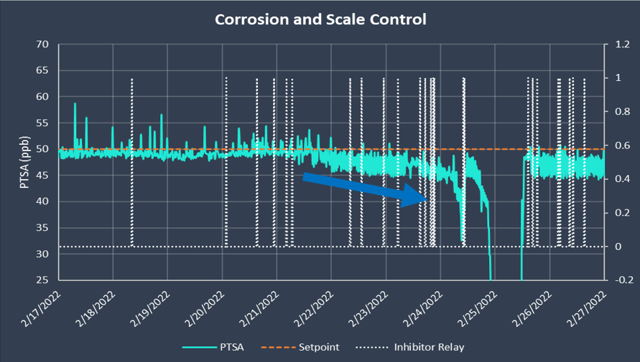

- Controls feed of scale and corrosion products based on configured ppm set point

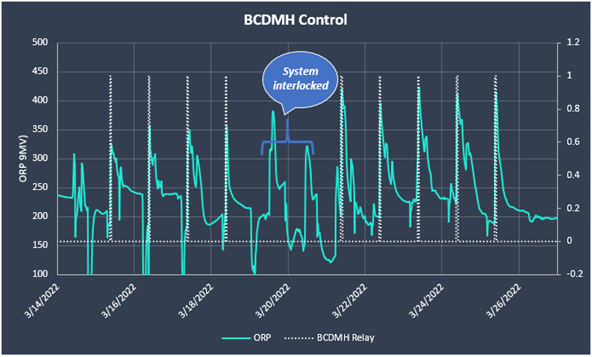

- Controls oxidizing biocide feed based on configured ORP set point or timer

- Controls non-oxidizing biocide feed based on configured timer

TIMER CONTROL

- Use timer control functions for your feed of BCDMH and Bio-Clear (DBNPA) products

- The graph below depicts a timer control BCDMH feed scheme. As seen, you see excellent ORP spike correlations with your BCDMH relay timer.

- Another option for BCDMH feed is utilizing the ORP setpoint functionality built into your control.

AND DELIVERS LIKE A SOLID

The simplicity of Smart Release Technology is why thousands of customers have switched to solid.

Smart Release Technology features:

-

Ergonomically friendly packaging

-

No chemical metering pumps needed

-

Eliminate drums and spill containment

-

Smaller footprint

-

Concentrated product reduces your carbon footprint

Download center

getting started with srg2

technical data sheets

Scale & corrosion tablets

Biocides