Why Are Coolant Additives Important?

WHY Coolant ADDITIVES?

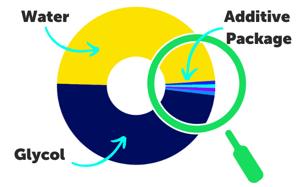

To answer the question “Why additives?” let's take a step back and look at what the purpose of a cooling system is in general and the components that are responsible for cooling it down. Because engines produce more heat than they can convert to useful work, engines have a cooling system to remove the wasted heat. The cooling system is responsible for controlling metal temperatures, nonmetallic material temperatures and the temperatures of other engine fluids. In the cooling system, you’ll find a coolant which is composed of water, some type of glycol and additives.

Water is very good at transferring the heat excess during convection cooling but has a low boiling point, high freezing point and is corrosive to metals. To make up for the low boiling point and high freezing point, coolants have glycol used to raise the boiling point and lower the freezing point. These two commodity chemicals make up about 95%-98% of the coolant. You may be asking yourself if 95%-98% of the coolant is made up of commodity chemicals, what differentiates all the coolants on the market?

While additives only make up about 2%-5% of the finished solution, you can think of them as the secret sauce to any great coolant. Because of water’s corrosive nature, adding these corrosion inhibitors into your coolant provides a coating film on the engine blocks to protect metals against cavitation erosion (liner pitting), corrosion, scale and dropout. In other words, coolant additives are important because they protect and extend the life of your most valuable assets.

Our product line addresses the wide variety of coolant formulations used throughout the world and includes both light-duty (automotive) and heavy-duty (diesel) coolants, rail, and marine applications. Each additive pack is extensively performance tested and meticulously designed for each application.

VIEW OUR PRODUCT CATALOG HERE