Single-Phase Direct-to-Chip Cooling: A Deep Dive into Dober Coolwave

In the realm of high-performance computing and data centers, managing heat efficiently is paramount. As processors become more powerful, traditional air-cooling methods struggle to keep up.

Enter Dober COOLWAVE, a cutting-edge single-phase direct-to-chip (DTC) coolant solution designed to address these challenges.

This blog delves into the mechanics of single-phase DTC cooling, its advantages, and how Dober COOLWAVE stands out in this domain.

What is Single-Phase Direct-to-Chip Cooling?

Single-phase DTC cooling delivers liquid coolant directly to the server’s heat-producing components, including CPUs and GPUs, for efficient thermal management.

Unlike two-phase systems that rely on the phase change of the coolant (from liquid to vapor), single-phase systems maintain the coolant in its liquid state throughout the cooling process. This method offers several benefits:

-

- Simplicity: Fewer components are needed, reducing system complexity.

- Reliability: The absence of phase change eliminates potential issues related to vapor formation.

- Efficiency: Direct contact with heat sources ensures optimal thermal management.

How DOBER COOLWAVE Enhances Cooling Efficiency

Dober COOLWAVE is engineered to maximize the benefits of single-phase DTC cooling.

Key features include:

-

- High Thermal Conductivity: Ensures rapid heat absorption from components.

- Non-Conductive Properties: Safeguards sensitive electronic parts from electrical shorts.

- Corrosion Resistance: Prolongs the lifespan of cooling infrastructure.

- Environmental Compatibility: Designed with sustainability in mind.

The Cooling Process: From Chip to Heat Rejection

The cooling cycle in a single-phase DTC system is straightforward:

-

- Heat Absorption: COOLWAVE coolant flows through cold plates mounted directly on the CPU/GPU, absorbing heat.

- Heat Transfer: The heated coolant is pumped to a heat exchanger or cooling distribution unit (CDU).

- Heat Rejection: The heat is expelled to the external environment, often through a radiator or chiller system.

- Coolant Recirculation: The now-cooled coolant returns to the cold plates to repeat the cycle.

This closed-loop system ensures continuous and efficient cooling.

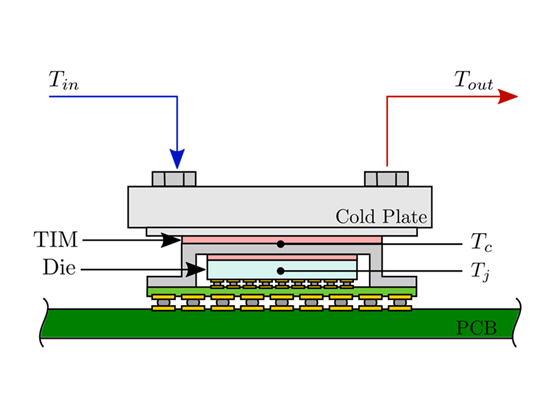

Visualizing the System

To better understand the single-phase DTC cooling process, consider the following schematic*:

Source: ResearchGate - https://www.researchgate.net/figure/1-Cross-sectional-schematic-of-a-single-phase-cold-plate-direct-to-chip-cooling-device_fig1_391597426

Advantages of Single-Phase DTC Cooling with COOLWAVE

-

- Enhanced Performance: By maintaining optimal temperatures, servers can operate at peak efficiency.

- Energy Savings: Reduced reliance on air conditioning and fans leads to lower energy consumption.

- Scalability: Easily integrates into existing data center infrastructures without major modifications.

- Sustainability: The environmentally friendly design aligns with green data center initiatives.

Conclusion

As high-performance computing demands continue to soar, keeping your data center cool is non-negotiable.

Dober COOLWAVE doesn’t just manage heat: it masters it. With the simplicity and efficiency of single-phase direct-to-chip cooling, COOLWAVE keeps your infrastructure running cool, fast, and sustainably.

And we don’t stop at off-the-shelf solutions. Dober can customizes to your exact specifications, delivering tailored cooling power that fits your unique needs. Why fit in when we can be built for you? Custom cooling, no compromises.

For more information on Dober COOLWAVE and how it can benefit your operations, visit Dober's direct-to-chip cooling page.

*Note: The schematic image provided is sourced from ResearchGate and is used for illustrative purposes. For detailed technical specifications and real-world implementations, please refer to the original publications and Dober's product documentation.