How a Bad Fuel Cell Filter-Coolant Relationship is Like Over-Mowing your Lawn

Fuel cell coolants have a vital job: transferring excess heat out of the system while also providing corrosion inhibition through various additives.

In a fuel cell system, filters are used to remove impurities and ensure the fuel and oxidant streams are clean before they enter the fuel cell stack. The filters used in fuel cell systems can vary depending on the specific application, but their general purpose is to protect the fuel cell stack from contamination that could damage the electrodes or reduce their performance.

- What a filter does in the fuel cell system

- The filter-coolant relationship

- Why rigorous testing is vital when determining compatibility of a coolant with a filter

Filters in Fuel Cell Systems

Fuel cell systems typically use several types of filters to ensure the fuel and oxidant streams are clean. For example, a fuel cell system that uses hydrogen as the fuel source may have a filter to remove impurities from the hydrogen gas before it enters the fuel cell stack. The filter may use a material such as activated carbon or a metal hydride to remove impurities such as sulfur compounds or moisture.

Similarly, the oxidant stream in a fuel cell system may also be filtered to remove impurities such as particulate matter, sulfur compounds, and other contaminants that could damage the fuel cell stack. The filter used for the oxidant stream may be made from materials such as activated carbon, alumina, or zeolites.

In addition to these primary filters, fuel cell systems may also use secondary filters to remove any remaining impurities in the fuel and oxidant streams. For example, a fuel cell system that uses air as the oxidant may have a HEPA filter to remove any remaining particulate matter or other contaminants before the air enters the fuel cell stack.

Overall, the use of filters is critical for ensuring the long-term performance and reliability of fuel cell systems by protecting the fuel cell stack from contamination and reducing the risk of damage or failure. Furthermore, mitigating the introduction of contaminants into the system is vital not only for safety, it can reduce Total Cost of Ownership (TCO) by having to keep using the same filter for longer.

The Filter-Coolant Relationship (Don't Over-mow)

When it comes to the relationship between your fuel cell deionizer filter and your coolant, you're looking for a certain level of equilibrium.

On the one hand, you want the filter to successfully filter out potentially harmful ions that make their way into the system during regular operation over time.

On the other hand, you'll want to make sure your coolant provider has done sufficient testing to ensure the filter does not strip vital additives from the coolant.

Think of it like mowing your lawn. After a long winter and a rainy spring, you might notice your grass start to grow at a rapid pace. Your first instinct might be to give your lawn a buzz cut.

But, as you might already know, cutting your grass too short is not good for your lawn. Cutting it too short leaves it prone to drying and damages its overall health. A widely accepted lawn maintenance rule of thumb is to never cut more than one-third the length of your grass at any one time.

Back to the topic at hand, the same holds true for the fuel cell filter-coolant dynamic. You want the filter to do its job in maintaining the integrity of the system, but not do it to the point that it's causing harm (i.e., filtering out additives).

What Happens If Your Filter, Coolant are Incompatible?

We've reviewed why a filter is important in the fuel cell vehicle: it removes potentially harmful particles that have made their way into the system.

You might not think of it this way, but what if your filter works ... too well? It's not so much working "too well" as it is working in excess of the parameters in which you'd want your filter to work.

In that case, the filter could actually strip additives from the coolant as it moves through the system. Without the additive package, the coolant cannot offer sufficient corrosion inhibition.

Insufficient corrosion protection can prove costly in several ways.

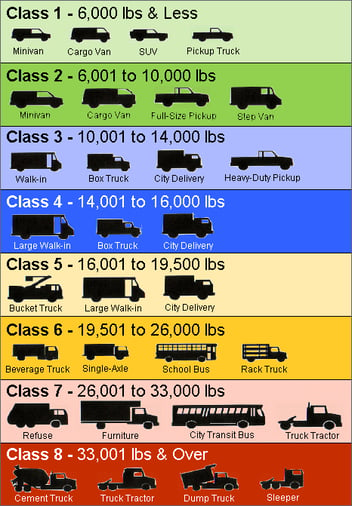

Firstly, there are costs associated with remediation of corroded engine parts. In turn, engine downtime can have real business implications. Let's use the commercial trucking industry as an example: if a truck is out of commission due to engine issues, that means a wrench thrown into a company's shipping schedules and, potentially, dissatisfied customers.

In summary, there is a potentially significant domino effect of negative consequences if your coolant and filter don't work together effectively.

Coolant Testing is Vital

As mentioned above, you want to make sure your coolant provider has tested its coolant for compatibility with whichever filter you will be using (or, if the provider has a filter that it is packaging with the coolant, that it has tested them together).

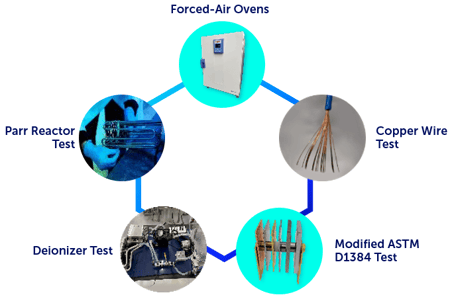

That means testing the coolant under fuel cell conditions. Here at Dober, we have carefully constructed our own deionizer rig for coolant testing. This rig complements a bevy of testing apparatus and procedures at Dober, including our forced-air ovens, D1384 test setups and much more.

Summary

As you can see, the filter-coolant relationship is a pivotal one. If the two don't work together in harmony, it can cause a lot of problems, both in terms of operating the vehicle and in business terms.

Bottom line?

- Without those additives protecting your system, you don't have corrosion inhibition.

- Without corrosion inhibition, you will see more ions in the system.

- With more ions, your filter has to work harder and will likely have to be replaced sooner than you'd want, which costs time and money (not to mention the safety hazards associated with operating a vehicle with excess ions impacting the fuel cell system).

That is why coolant manufacturers often package their finished coolant with a filter of their own, one they have tested with the coolant to ensure important additives do not get stripped too early in the expected life of the coolant.