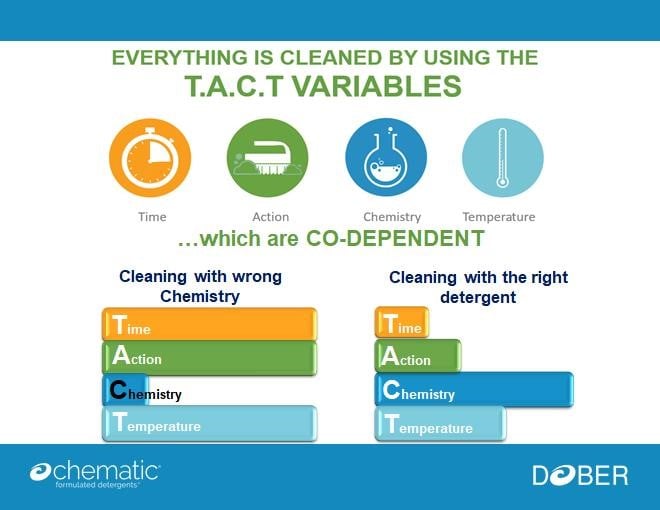

What is TACT and Why is It Important?

The key to a successful cleaning study is providing a recommendation that not only removes the soil but is also the most optimal for that application. All coupon studies performed in the Chematic laboratory are used to determine the optimal cleaning applications for any type of soil and residues. We perform these studies using our T.A.C.T variables (Time, Action, Chemistry and Temperature), which are all taken into consideration and refined before a recommendation is given. While using T.A.C.T, each of these variables are proportional to one another. If one aspect is increased, for example, better Chemistry, then the others such as action or time could be decreased. Utilizing the right detergent Chemistry can give companies the ability to decrease all other variables and increase production.

What Does T.A.C.T Stand For?

Time

While something like time might sound like a simple optimization variable, it can be complicated based on the soil and its preparation. The contact time in which the cleaning agent is exposed to the soil is very important for efficient cleaning. If the residue is not exposed to a long enough cleaning cycle where all areas can be exposed, soil removal can become more difficult. We not only have to consider the time of the detergent step(s), but also the length of pre-rinse and final rinse steps. For some soils, increasing a detergent step may not always be the most beneficial idea for two reasons.

First, if temperature cannot be maintained, a longer soak time may not be the best choice as increasing the length of the step will increase the loss in temperature in the equipment. This could in turn affect cleanability and the potential to foam, which could cause larger issues in CIP operations.

The second reason why increasing the time of a detergent step may not be effective, is the ability for the cleaning agent to suspend soil. If the detergent has reached carrying capacity, then any soil left may continue to mix around and redeposit or cause other issues. So, while it can be ideal to have one long detergent step, it is not always the most effective. The length of pre-rinse matters because it may remove or loosen soil before a detergent step. Also, if a pre-rinse proves to be effective, it is important to scale the pre-rinse time to be in line with the length of a detergent step, such as a 10-minute pre-rinse for a 30-minute detergent step, which is adjusted if the detergent time increases (i.e. 20 min. pre-rinse for 60 min. detergent step).

Possibly one of the most important time variables is the time for a final rinse. Final rinses are used to remove any detergent and possible soil left in the equipment. Some detergents need more rinsing in order to fully remove it from the surface. If a rinse is not long enough, there may be detergent residue left behind that can be discovered upon swab testing or the equipment drying.

Action

Action is the type of cleaning method that will be chosen to be in contact with the soil, that is decided based upon the capabilities of the client. We have multiple forms of actions/scale-up capabilities in our laboratory including beaker with minimal stir bar action, scrubbing/wiping, trigger spray, laminar flow, and CIP. All projects start as beaker trials with the minimal stir bar action that allow us to evaluate detergents. We also use this method for clients who only have fill, soak, and agitate capabilities.

For clients who only have manual intervention capabilities, we can scrub with brushes or sponges and wipe with lint-free cloth. Trigger spray is our method used to replicate low-pressure spray guns/balls and some power washers. Our laminar flow is designed to replicate the cascading flow of a static spray ball from a coating pan or CIP systems where direct impingement cannot be achieved. For large scale-up projects, we have a pilot CIP system that can be programmed to replicate most clients’ CIP capabilities. Having an array of different types of actions allows us to replicate customers’ processes and give the most accurate cleaning recommendations.

Chemistry

Out of all four TACT variables, Chemistry is the first one we assess. Our aim is to allow the Chemistry of the detergent, rather than the Action of the cleaning process, to accomplish the majority of the cleaning. During the detergent screening process, we will leverage our extensive portfolio of critical cleaning agents that are best suited for the customer’s soil and cleaning process. This screening can involve more detergents if the soil is more difficult or if a clean result becomes difficult to achieve with a single detergent. Chemistry is evaluated from multiple aspects during this detergent screening. We will choose detergents based on the soil key components, pH, and employee safety. Screening can be performed in two ways.

The first can be a dissolution study, where we place a small amount of soil into a test tube with detergent solution at a commonly used cleaning concentration. We use this method to watch how long soil stays suspended in the detergent.

The other method we evaluate is in a beaker with minimal action so that we can fully focus on how the soil is removed from stainless steel or other materials. Once we have knowledge of the most effective detergent, we can focus on the other three T.A.C.T variables to completely remove the soil.

Temperature

Temperature is a very important optimization factor in the cleaning process. We focus on the temperature of all cleaning steps and not just detergent steps. If temperature isn’t optimized correctly in each step, there is the risk that soils will not be removed or that other cleaning issues will arise. When it comes to pre-rinses, room and heated temperature steps can be used. However, we do take caution with heated pre-rinses depending on the type of soil. If we have a soil with pigments, we may not use a heated pre-rinse as this may cause the hazes to become worse and be more difficult to remove during the detergent step. One instance where we may not use hot pre-rinses or hot detergent steps at certain customer site is flash drying. Depending on the components and addition order of the soils, using high temperatures during cleaning may cause the soil to flash dry onto the equipment surface (ex. mixing vessel). Another example is when hot pre-rinses can cause polymers to flake instead if breaking into smaller particles or, at times, cause soils to swell when in contact with water, preventing detergent entry during the detergent step.

When it comes to detergent steps, Dober wants to use the optimal temperature that performs effectively for the residue. In most cases, having the ability to use temperature is helpful in the cleaning process, but is not always needed. Some soils can be cleaned with room temperature detergent step or without the ability to maintain heat, in which case, any heat may be helpful in the cleaning process. At this point, we will test all temperature ranges that we believe will be effective in soil removal.

Our detergents perform more effectively when they are used within their optimal temperature range that makes it easier to remove soils and helps avoid the production of foam. A cloud point is the temperature where surfactants are released from the formula causing the solution to cloud, which allows for effective cleaning. Foam generation occurs the least when the detergent solution is at or above the cloud point. When the detergent solution is at room temperature or unmaintained, foam generation will begin to occur with increased exposure to action. If there is little action used in the cleaning process, then room temperature detergent steps may be considered.

At Dober, we don’t just give you a recommendation for a detergent. We put in the time, effort, and knowledge to give you a full cleaning process that will optimize your assets. Your capabilities and parameters matter to us and that is why T.A.C.T is our frontline for Critical Cleaning Evaluations.