CCE Journey – How We Replicate Your Process

When it comes to giving the optimal cleaning recommendation, understanding the customer’s soils & cleaning conditions is essential. Each type of soil and what equipment it encounters determines how it is replicated as accurately as possible on a lab scale. Having as much detail from customers as possible can help create the most accurate representation of their soil and the issues they face.

Knowing everything from processing conditions, temperature ranges, dirty hold times, types of material, and steps taken can lead to passing a failing result. No detail is too small as the information that most might find insignificant, could be the step that causes the issues and failures in replication. Believing that the component with the highest percentage in a formulation is the key component for cleaning could become the difference between a passing recommendation and a failing customer trial. Sometimes the smallest components or rinses can cause variation in trials from lab scale to scale up. We are here to optimize our customer’s time and resources, but in order to be effective, we need the customers to trust us with the information we request.

Knowing everything from processing conditions, temperature ranges, dirty hold times, types of material, and steps taken can lead to passing a failing result. No detail is too small as the information that most might find insignificant, could be the step that causes the issues and failures in replication. Believing that the component with the highest percentage in a formulation is the key component for cleaning could become the difference between a passing recommendation and a failing customer trial. Sometimes the smallest components or rinses can cause variation in trials from lab scale to scale up. We are here to optimize our customer’s time and resources, but in order to be effective, we need the customers to trust us with the information we request.

Soils

Replicating a soil is more than just following a sheet of components. Paying close attention to the materials of construction, heat exposure, the stage of manufacturing, and addition order can impact proper soil replication and if these details are missing, could lead to inaccurate replication and eventually cleaning failures on the customer end. Having informative conversations to find out these extensive details helps us replicate a soil right the first time. We make sure to take step-by-step notes and pictures of all results and processes so we can consult with customers to make sure our replication is what they see. Once we know the process is replicated as closely as possible, we go the extra mile with our testing. All passing trials will be performed in triplicate to make sure that our results are 100% of what you need.

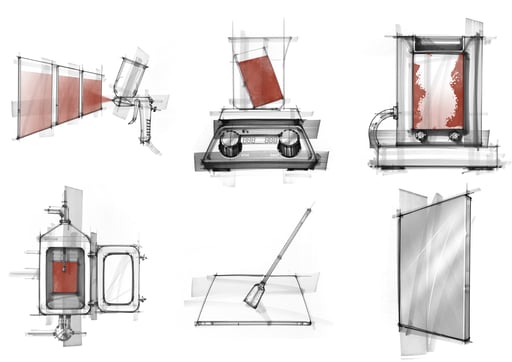

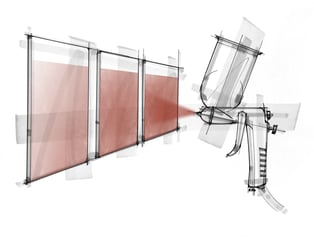

Coatings

Coating replication can differ depending on whether it is aimed at cleaning the preparation vessel/mixing vessel, the coating residue in a coating pan, fluid bed or simulating heavy and long campaigns before cleaning. A coating pan, having the ability to continuously mix and allow for even coating and slight drying time in between layers, is the hardest aspect to recreate. Also, recreating coating batches with different alternating coatings poses an even more difficult challenge. In our experience, using a hand-held spray gun and a multi-setting heat gun to atomize the coating mixture onto the surface of a stainless-steel coupon and drying in between the soil layer is the most effective replication.

This process allows for a similar soil level to be deposited onto the coupon as you would see on a stainless-steel pan from the spray guns soiling the sides and back of the pan coater. When it comes to mixing vessels and long/heavy campaigns, these are usually replicated the same way on a lab scale. Once the coating is made, a 10 mL syringe is used to “pool” a 2-3 mL layer of coating onto the entire coupon surface. This replication acts as a thick coating sitting in the bottom of a mixing vessel that dries together or multiple campaigns being performed drying on top of each other before a cleaning to make a ‘hard to remove’ layer.

Granulation

Granulation is performed in many types of equipment with differing types of friction and some heat potential. For a granulation (dry mixing) that would be mixed gently in a V blender, we mainly dust the soil over the coupon surface. For higher friction equipment such as rapid mixer granulators (RMG) and ribbon blenders, we have a different method to apply the soil. Small scoops are used to place the granulation onto the bottom two-thirds of a stainless-steel coupon. This small scoop is then compressed and rubbed into the surface of the coupon in a circular pattern. This allows for varying amounts of soil to be spread on the coupon. The main compression is heavily soiled while the rest of the coupon has an even or light layer of soil.

Cosmetics

Cosmetics is a big market with a large variety of products like lotions, face scrubs, make-up, powders, and oils. The manufacturing of cosmetics can be performed in mixing vessels, holding or mixing equipment for powder, and kettles for melting waxes and oils. Most cosmetics of any kind are replicated in the same fashion. A layer of soil is spread onto the coupon surface to the best ability. Some can be difficult to spread and may need to be melted down in order to get a comparable amount of soil on the coupon as you would see in a mixing tank or a mold. If any soils are exposed to heat during any section of the manufacturing process it will be taken into consideration in the lab-scale replication. One of the biggest factors in cosmetic cleaning is the pigment and powder residues left behind. Cleaning a finished formula may sometimes be easier than removing the pigment from holding equipment. It is important for us to understand all types of residues in order to clean them. If we do not properly replicate this process and give a recommendation that seems to clean, there is the potential that any material left behind will condone microbial growth.

Sunscreens

Sunscreens are our most complex replications based on so many varying ways they are manufactured. Sunscreens are formulated in many different orders of addition mixes and some ingredients have the possibility to be exposed to heat. For sunscreens, we have the option of spreading, baking or layering with baking.

Sunscreens are our most complex replications based on so many varying ways they are manufactured. Sunscreens are formulated in many different orders of addition mixes and some ingredients have the possibility to be exposed to heat. For sunscreens, we have the option of spreading, baking or layering with baking.

Our first replication is spreading a thick even layer over a coupon surface to replicate the soil left over after draining a tan.

Next, we have replication where we spread the same thick layer but then bake the coupon in the oven for a predetermined amount of time as some sunscreens are heated while in a mixing vessel. This exposure to heat can create a different level of residue and sometimes, make the soil more difficult to remove.

The last type of replication would be layering with heat. Sometimes different layers of soil are created due to the order in which materials are added to a product and mixing tank. For some sunscreens, powdered materials can be added to a hot mixing tank and can be flash dried onto the surface on the top and bottom. Then, the rest of the materials are added, possibly at a different level of the tank, and the sunscreen is mixed creating layers. For our replications, for example, we would add a liquid layer of sun spheres to the coupon surface and bake those on for a predetermined amount of time. Once those coupons are cooled, we would then spread a thick layer of sunscreen over some of the sun spheres to represent the layer of soil on the tank. Sun sphere on top, overlap of sun sphere and sunscreen, and then the sunscreen on the bottom. These have proven to be some of the hardest soils to replicate and the hardest to clean. Sometimes the best way to soil is to look at the process and not just the result.

Oils

Oils can be soiled in two different ways for replication. Either they are put onto the coupon and allowed to spread, or the soil is put onto the coupon and baked for a predetermined amount of time. Oils that are just spread are usually soybean oils or powders mixed with oils.

Other Considerations for Replication

Cleaning Process

We have multiple ways to replicate customers cleaning abilities on a lab scale. Our most common replication is a beaker coupon study which is used for two reasons.

The first main use for this replication is for us to investigate cleaning chemistry with a minimalistic approach to action by only using a stir bar. This allows us to screen our detergents to narrow down what works best on the soil before moving to more steps or different types of action. The second reason we use this method is for those who have minimal action available and can fill, soak, and agitate their equipment.

The second method we can replicate with possibly the most accuracy is manual cleaning. We can do scrubs with brushes, different types of cloth, and sponges depending on what manufacturers use.

If we need to scale up further, we have a couple of ways to do that. Using spray bottles can simulate low-pressure spray balls or power washers and laminar flow devices simulates the spinning of a coating pan through the detergent solution or CIP systems where direct impingement cannot be achieved. Our best scale-up tool for replications of tanks with spray balls and high-action cleaning is our CIP tank. This rig can be programmed to replicate most clients’ systems.

Water Quality Types

An aspect of cleaning replication that may not always be thought of as an important component is the type of water the client is using. Using DI water over hard or potable water can sometimes result in a big difference in the results of a project. Our lab can use DI water, and potable water or make hard water that matches the hardness at the client’s facilities.

Temperature Ranges

We also make sure to keep temperature abilities in mind, whether this is the temperature that the soil is exposed to or the temperature capabilities of the equipment and detergent solution. We can keep constant heat as well as perform projects with no heat or unmaintained heat. These factors can determine how well a detergent solution cleans and how long it takes to remove the soil.

Types of Material (MOC)

Some replication involves different types of soils to be cleaned off different materials of construction. Not all projects involve cleaning equipment made from SS316 or SS304 stainless steel. Most projects are done on stainless steel, but sometimes, clients need to clean out hoses, piping, filters, floors, or glass. We procure most materials for any project to have a proper replication.

Conclusion

Overall, the replication of a company's process is just as important as the cleaning itself. Every detail - no matter how small - can contribute to proper replication and the best results. Temperatures of the cleaning cycles can determine how effective a detergent is at removing a soil. However, the right detergent may not be useful if the soil is not replicated correctly, whether that is heat exposure, friction, compression, or spreading.

Whatever processes and challenges you face are the same ones we make important. Optimizing your time and resources is our goal.