HOW TO CLEAN PIGMENTED FILM COATING

Film coating in Pharmaceutical and Nutraceutical manufacturing

Since ‘pills’ were invented, Tablet Coating has been an important requirement for aesthetic and functional purposes. In the early days, slippery plant extracts were used to improve swallowability. Coating with gold and silver, as recently as the 19th century, helped with ease of swallowing as well as their palatability. After the 1800s, sugar coating was widely used to improve the appearance and patient compliance of tablets.

As the complexities of formulations increased, film coating took over sugar coating because of the ease & speed of application as well as the lowered weight build-up. Pigments are incorporated into these coatings to identify tablets and excipients such as Titanium dioxide are used for uniformity of color and light protection.

How to Clean Pigmented Film Coating?

While the polymers commonly used in film coatings are not very difficult to clean by themselves, it's the added pigment that leaves behind a haze, which becomes a cleaning issue over time. These pigments have the tendency to bond to the stainless steel and need scrubbing to be separated from the equipment surface, resulting in longer cleaning cycles.

Current Industry Trend

Because the polymers clean up easily, it is quite difficult to identify the cleaning problems initially. After a few cleaning cycles with the wrong detergent, a tint or a haze develops that builds up over time, which cannot be cleaned easily, even after a thorough cleaning. Those who are aware of this problem use the traditional cleaning procedure that includes a two-detergent process of alternating highly alkaline detergents for the polymer and highly acidic detergent for the insolubles.

- The procedure is time-consuming with multiple alternating detergent and re-cleaning steps, especially with film coatings containing high polymer. This increases equipment downtime and decreases productivity

- Manual scrubbing is necessary to get rid of the pigment haze and can be cumbersome for larger equipment

- Due to the use of highly alkaline and acidic detergents, EHS concerns could arise. For manual cleaning, this is a safety risk

- Due to multiple-detergent and multi-step process, there is excessive water consumption

The other cleaning methods include the use of water, plain alkaline detergent and/or solvents. In this case, the chemical strips away the polymer but doesn’t address the pigment residue, which is observed once the equipment is dry. Removal of this haze, once separated from the formulation residue, is extremely tough and needs extensive action/scrubbing making it a highly time-consuming process.

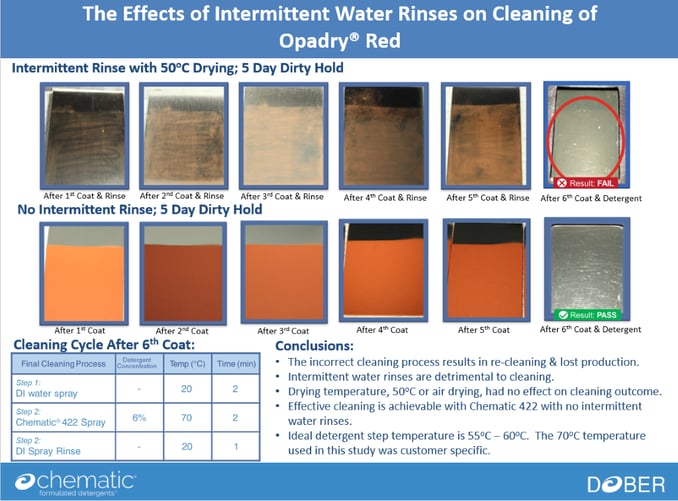

Intermittent Cleaning is Doing More Harm Than Good

To help clean faster, some companies use intermittent water washes for minor cleaning cycles, without which, their existing cleaners cannot clean residue left behind by campaign batch processing. With internal lab studies, we have proven that this is not a good idea as it causes heavy hazes that are very difficult to clean.

- It worsens the pigment adherence to the equipment surface due to the hot drying cycle after intermittent washings

- Due to the intermittent wash and drying time, equipment downtime is further reduced which has a negative impact on productivity

- With multiple cleanings between campaign batches, water consumption is increased

Efficient Cleaning of Film Coating With Chematic® Cleaners

Although changing a cleaning detergent requires cleaning Validation, one must consider the overall productivity and downtime reduction achieved by changing over to Chematic®. To help speed up this process, Dober also provides process optimization and validation support.

"the total downtime was reduced by about 700 hours per year"

As proven with production scale studies at Syntegon (Previously Bosch-Huttlin) on coating pans, Chematic® 422 does not require minor cleaning with water and is capable of cleaning polymer and pigment after campaign batches with optimized process.

Based on this case study, cleaning times for a highly pigmented Opadry® coating in an XL COTA 350 coating pan were reduced from 4 working shifts to 4 hours of cleaning, without intermittent cleaning + drying step after every coating. Based on the production volume, the total downtime was reduced by about 700 hours per year, giving them time for additional 100 or more coating batches, thereby increasing manufacturing capacity. In addition to the increased manufacturing capacity, cleaning with Chematic® 422 minimizes or even eliminates manual cleaning, which, in the current times of social distancing, would ensure faster cleaning with minimum manual interaction for operator safety against Covid-19 during manufacturing operations.

Recommended Cleaner: Film coating containing HPMC/PVA/ HPC and pigments like titanium dioxide & iron oxides (Opadry®, Nutrafinish®)

Recommended detergent/cleaner: Chematic® 422

Recommended Procedure:

- Water Pre-rinse at ambient temperature for 5 – 10 minutes (if formulation contains pigments, do not use water above 50° C for pre-rinse)

- Dilute the detergent to ~ 6% v/v (this can be optimized between 3 – 8 % depending on the residue amount, residue thickness, and pigment content) with hot water (40 - 50° C for manual / fill, soak and agitate, ~ 50 - 65° C for CIP – Automated) and soak the equipment (soiled portion) for 30 minute – 1 hour with mild agitation (blade rotation for RMG / Pan rotation for coater / Recirculation through Spray balls in CIP for equipment like FBE/ stirring for lab scale).

- Ensure that the entire residue is soaked for the given time period as un-soaked residue doesn’t easily get cleaned even with scrubbing

- For this polymer, soaking/detergent contact time is more important than scrubbing

- Post-rinse is to be done immediately after the detergent solution is drained to prevent the drying of the detergent solution onto the surface of the equipment. For manual cleaning, gentle scrubbing/wiping is to be done before rinsing.

Please note that the process steps outlined above are meant to be starting points for cleaning cycle development.

Have Cleaning Problems? We'd Love to Help

Our mission at Chematic is to Protect people and their environments through cleaning solutions. We'll continue doing our part in maintaining consumer, personnel, and environmental safety by manufacturing Chematic Detergents for our customers so they can spend more time producing lifesaving drugs and less time cleaning.

If you are interested in discussing a cleaning process based on your coating process and cleaning capabilities, reach out - we're here to help.