How To Clean Enteric Polymers

Why Common Approaches Are Not Effective

The mechanism of action for cleaning enteric polymers is straightforward. Because enteric polymers are chemically acidic, their solubility and therefore their release is pH dependent. As a result, one would assume that they can be easily cleaned with alkaline chemistry or detergents.

The wrinkle to this simplistic view is that the polymers are rarely used on their own. They are formulated with other excipients to improve their processing efficiency, improve film or matrix properties, or extend their shelf life. Furthermore, coloring pigments such as titanium or iron oxide are frequently added into the enteric coating formulation. The result is often a tough and sticky residue bonded to the stainless steel.

Similar to how a hammer will put a screw into the wall, traditional approaches to cleaning enteric polymers will get the job done, but it won’t be pretty and there will be repercussions down the road.

Common Approach 1: A two-detergent process of alternating highly alkaline detergents for the polymer and a highly acidic detergent for the insolubles (Pigment/oxides). Challenges with this approach include:

- Time-consuming procedure

- Re-cleaning is often required when residues contain high pigment quantities.

- Decreased productivity as a result of increased equipment downtime

- Manual scrubbing may be necessary to remove pigment haze

- Due to the use of highly alkaline and acidic detergents, safety is of concern, especially when manual cleaning is required

- Excessive water consumption due to multiple detergents and multi-step process

Common Approach 2: Use of commodity products like sodium bicarbonate, sodium hydroxide, and solvents. Challenges with this approach include:

- Chemical strips away the polymer but doesn’t address the talc or pigment residue

- Time-consuming: Removal of this haze once it is separated from the formulation residue is extremely tough and needs extensive action such as scrubbing

- Manual scrubbing may be necessary to remove pigment haze

- Due to the hazards of sodium hydroxide and solvents safety is of concern, especially when manual cleaning is required

Efficient Cleaning of Enteric Polymers

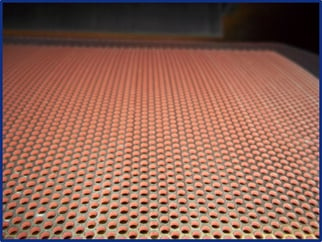

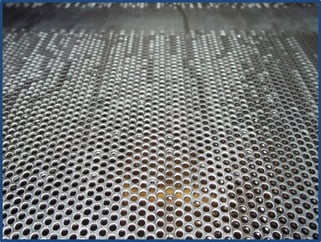

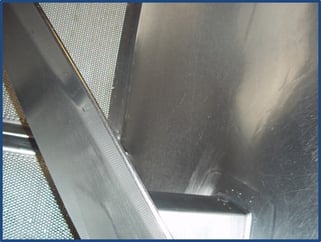

Although I’m not a handy [wo]man by any stretch of the imagination, I want to revisit the hammer and the screw analogy. There are thousands of different shapes and sizes of screws, and depending on if you are screwing into drywall, plaster, or concrete, you will need to make sure you match the right tool with the unique project at hand. The case at hand is a great example of requiring a detergent and process that target not only the enteric polymer but the other ingredients too. If you want your equipment to look like this without manual scrubbing, then read on!

Here is the 3-step process we recommend for cleaning enteric polymers:

1. Select the Right Detergent

- Enteric Polymer: Acryl-EZE®, Cellulose Acetate Phthalate

- Recommended detergent/cleaner: Chematic® 454

- Enteric Polymer: Methyl acrylate-methacrylic acid copolymers (Eudragit® L 30 D-55, L 100-55, L 100, L 12.5, S 100, S 12.5, FS 30 D)

- Recommended detergent/cleaner: Chematic® L/S Plus

- Enteric Polymer: Eudragit® FL 30 D-55

- Recommended detergent/cleaner: Chematic® FL Cleaner

- Enteric Polymer: Shellac

- Recommended detergent/cleaner: Chematic® 1

2. Follow Recommended Cleaning Procedure:

Step 1: Pre-rinse with Water-

- Temperate: Ambient temperature

- Time: 5 – 10 minutes

- Note: if the formulation contains pigments, do not use water above 50° C

-

- Cleaning Temperature:

- If manual soak and agitate: 20 - 50° C

- If CIP/automatic: 50 - 65° C

- Cleaning Time:

- If manual: as required

- If CIP/automatic: Soak the equipment (soiled portion) for 30-60 minutes with mild agitation

- blade rotation for RMG

- Pan rotation for coater

- Recirculation through Spray balls in CIP for equipment like FBE/ stirring for lab scale

- Additional Notes:

- Ensure that the entire residue is soaked for the given time period as un-soaked residue doesn’t easily get cleaned even with scrubbing

- For this polymer, soaking/detergent contact time is more important than scrubbing

- Post-rinse is to be done immediately after the detergent solution is drained to prevent the drying of the detergent solution onto the surface of the equipment. For manual cleaning, gentle scrubbing/wiping is to be done before rinsing.

- Cleaning Action: This process is a good starting point for CIP, WIP, blade rotation, or pan rotation

- Cleaning Temperature:

Step 3: Optimize

-

- The process steps outlined are meant to be starting points for cleaning cycle development. Depending on the exact residue and thickness, we often test dilution ranges from 2-8% and various other variables listed above. To discuss a cleaning process based on your coating process and cleaning capabilities please contact Dober’s Chematic Division

Efficient Cleaning of Enteric Polymers

Efficient cleaning of Enteric polymers requires targeting the entire soil, not just the polymer. Our laboratory can replicate your soil and evaluate different cleaning detergents and processes. The image below is a representation of a coupon study that has simulated an enteric polymer with iron oxide in order to ensure we provided a solution for their soil and not just the enteric polymer.

The industry trends of improving production efficiencies and increasing the safety of the environment and the processes for employees give cleaning optimization an opportunity to play a key role in helping production teams reach their goals.