Sustainable water treatment biopolymers are something businesses across a number of industries are leveraging.

Using sustainable water treatment biopolymers means:

- Better outcomes for our environment

- Positive branding for a company (i.e., developing a "green" reputation as an implementer of sustainable practices)

- Helps to ensure compliance with environmental regulations

According to one market research report from December 2023, the global biopolymer and bioplastics market was set to grow from $34.5 billion in 2022 to $93.1 billion in 2023.

Bottom line: interest in sustainable processes with biopolymers is growing ... and fast.

As the sustainability movement continues to grow, companies will increasingly seek to solve the challenges of "How do I become more sustainable ... while maintaining performance and keeping my costs down?"

Biopolymers are heroic macromolecules: adaptable, versatile, and capable of dealing with all sorts of problems.

In the context of water treatment, biopolymers play a crucial role as environmentally friendly and sustainable materials. Biopolymers are natural or synthetic polymers produced by living organisms or derived from renewable resources. In water treatment applications, biopolymers are utilized for various purposes, including flocculation, sedimentation, and as coagulants.

Examples of biopolymers include:

-

Cellulose: This is the most abundant natural biopolymer, found in the cell walls of plants. It's used to make paper, textiles, and biodegradable plastics.

-

Starch: Extracted from plants like corn and potatoes, starch can be processed into bioplastics used for packaging, bags, and disposable tableware.

-

Proteins: Examples include silk (from silkworms) and wool (from sheep). These biopolymers are used in textiles, as well as in medical applications for drug delivery and tissue engineering.

-

Polylactic Acid (PLA): Derived from corn starch or sugar cane, PLA is a popular bioplastic used in disposable cutlery, transparent cups, and 3D printing.

-

Chitin and Chitosan: Found in the exoskeletons of crustaceans and insects, these biopolymers are used in water treatment, cosmetics, and as a biodegradable film for food packaging.

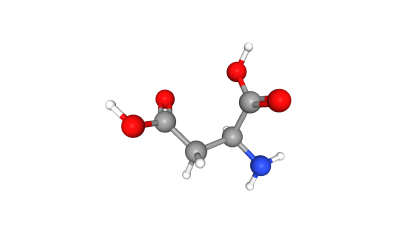

Simply put, biopolymers are macromolecules assembled from multiple monomers. For example, polyaspartic acid is an example of a biodegradable polymer, and is often sold in industrialized form as a polyaspartic acid sodium salt.

Biopolymers in water treatment can enhance the removal of impurities and particles from water through the formation of flocs. These flocs aggregate suspended solids, impurities, and contaminants, facilitating their separation from the water. Biopolymers such as chitosan, alginate, and starch-based polymers have shown promise in improving water treatment efficiency due to their biodegradability and low environmental impact.

The use of biopolymers in water treatment aligns with the growing emphasis on sustainable and eco-friendly solutions. By replacing traditional chemical coagulants with biodegradable and renewable biopolymers, water treatment processes can become more environmentally responsible. This shift not only addresses water quality concerns but also contributes to the overall goal of promoting sustainability in water management practices.

In the context of water treatment, biopolymers play a crucial role as environmentally friendly and sustainable materials. Biopolymers are natural or synthetic polymers produced by living organisms or derived from renewable resources. In water treatment applications, biopolymers are utilized for various purposes, including flocculation, sedimentation, and as coagulants.

Biopolymers in water treatment can enhance the removal of impurities and particles from water through the formation of flocs. These flocs aggregate suspended solids, impurities, and contaminants, facilitating their separation from the water. Biopolymers such as chitosan, alginate, and starch-based polymers have shown promise in improving water treatment efficiency due to their biodegradability and low environmental impact.

The use of biopolymers in water treatment aligns with the growing emphasis on sustainable and eco-friendly solutions. By replacing traditional chemical coagulants with biodegradable and renewable biopolymers, water treatment processes can become more environmentally responsible.

This shift not only addresses water quality concerns but also contributes to the overall goal of promoting sustainability in industry.

You can find biopolymers being used in industries like:

- Packaging

- Biomedical

- Agriculture

- Cooling Towers

- Oil and Gas

- Textiles

Biopolymers can be used for everything from environmentally friendly packaging to medical implants (Baranwal et al). They're the do-it-all macromolecules that can make life better for humans, not to mention all other lifeforms sharing this planet with us.

When we talk about biopolymers, they're typically lauded for their biodegradability and how safe they are for the environment.

But what about synthetic polymers? How are they different from their natural counterparts?

Synthetic polymers are mostly derived from petroleum or natural gas products through polymerization. They include polyacrylates, polyacrylamide, polyamines, poly DADMAACs, and poly (ethylene oxides), etc.

Natural polymers originate from plant or animal sources and include lignin, tannins and polysaccharides.

Semi-synthetic (sometimes called organic) polymers are produced through chemical or biological modification of natural polymers. Natural and organic polymers are currently receiving a lot of attention due to their advantages over conventional synthetic polymers or inorganic agents.

Biodegradability, non-toxicity, ability to undergo different chemical modifications and availability from renewable sources are the major advantages of natural polymers.

We wanted to zero in on one powerful molecule with which Dober has a lot of experience: the amino acid L-aspartic acid, a powerful ingredient in the production of the biopolymer product polyaspartic acid sodium salt (which is part of the wider polycarboxylate biopolymer group).

Dober's biopolymer product Aspartyl is based on the extremely versatile L-aspartic acid (the L-enantiomer of aspartic acid). In fact, aspartic acid is an amino acid made naturally in the human body.

In the industrial world, it can be used in a wide variety of capacities. As a biopolymer in the form of polyaspartic acid sodium salt, L-aspartic acid is the engine that can make for better water treatment in the oil and gas, cooling tower and agriculture sectors, to name a few.

The amide backbone of aspartic acid gives it special properties.

It is also...

- Biodegradable

- Non-Toxic

- Adsorbent onto surfaces

...meaning aspartic acid can be the backbone of a sustainable and effective water treatment operation.

In the oil and gas industry, for example, polyaspartic acid can inhibit the formation of calcium carbonate and calcium phosphate on equipment (more on the oil and gas sector below).

We've touched on the chemistries and the industries that currently benefit from sustainable water treatment with biopolymers, including those based on l-aspartic acid, like Dober's Aspartyl product line.

Now, let's dive further into the latter and talk about end-user problems that are solved with biopolymers for sustainable water treatment in a wide variety of applications.

What are some problems biopolymers can solve for industries? Below we'll review a few, although biopolymers' exceptional versatility make them useful in many other industries.

For the oil and gas industry, one major problem operators come across is scale deposition in oilfield equipment.

Over time, scale can develop within oil production equipment, both above and below ground, that can lead to "formation damage, loss in production, pressure reductions, and premature failure of down hole equipment" (Kamal et al)¹.

The use of biopolymers — like those based on L-aspartic acid mentioned above — in the oil and gas industry is not only beneficial for improving operational efficiencies and recovery rates but also for addressing environmental concerns associated with these operations. By integrating biopolymers into their processes, the industry can move towards more sustainable and environmentally friendly practices.

Biopolymers used in the oil and gas sector include (Shunxiang et al)²:

- Xanthan gum, Scleroglucan and cellulose and their derivatives are used as thickness agents in the drilling and production process

- Guar gum and Guar gum derivatives are applied to form crosslinked gels for proppant transportation in hydraulic fracture

- Chitosan is utilized as oil adsorbent in wastewater treatment

But that's not all biopolymers can do. Below we've compiled a short list of what biopolymers can do in the oil and gas sector.

Corrosion Inhibitors

Some biopolymers have properties that can inhibit corrosion in pipelines and equipment. By forming a protective layer on metal surfaces, they can reduce the corrosive effects of water, chemicals, and gases encountered in oil and gas production and transportation.

Scale Inhibitors

Biopolymers can also serve as scale inhibitors, preventing the formation of mineral deposits (such as calcium carbonate) in pipelines, wells, and reservoirs. These deposits can block flow and reduce the efficiency of oil and gas production.

Bioremediation

In the context of environmental management, biopolymers can be used in bioremediation processes to treat oil-contaminated soils and waters. Certain biopolymers can stimulate the growth of microorganisms that degrade hydrocarbons, aiding in the cleanup of oil spills and leaks.

Drilling Fluid Additives

Biopolymers are used as additives in drilling fluids to enhance viscosity, control fluid loss, and improve the lubrication properties of the drilling mud. These biopolymers help in stabilizing the wellbore, cleaning the drill bit, and carrying cuttings to the surface. Xanthan gum and scleroglucan are examples of biopolymers used for this purpose.

Enhanced Oil Recovery (EOR)

In enhanced oil recovery processes, biopolymers are injected into reservoirs to improve the displacement efficiency of oil. They act as mobility control agents to increase the viscosity of the displacing water, improving its sweep efficiency through the reservoir and thereby increasing the amount of oil recovered. Biopolymers used for EOR include xanthan gum and other polysaccharides.

Fracturing Fluids

Biopolymers are utilized in hydraulic fracturing (fracking) operations as components of fracturing fluids. They help to increase the viscosity of the fluid, which is essential for carrying proppant (sand or other particulate material) into fractures in the rock formation. Once in place, the proppant keeps the fractures open, allowing oil or gas to flow more freely to the production well.

Gas Hydrate Management

Biopolymers are explored for their potential in preventing or managing gas hydrates, which are ice-like structures that can form in deepwater pipelines and obstruct the flow of oil and gas. Some biopolymers can inhibit the formation of these hydrates or help disperse them if they form.

Biopolymers are increasingly used in the agriculture industry to address various sustainability and productivity challenges. Their biodegradability, non-toxicity, and renewability make them particularly appealing for numerous applications, ranging from crop production to waste management.

Here are some key areas where biopolymers are utilized in agriculture:

Nutrient uptake

Biopolymers can be used in to help increase nutrient uptake, which can help reduce the amount of fertilizer needed. In one study, a research team analyzed the impact of biopolymers (derived using alkaline hydrolysis on municipal waste). They concluded that use of biopolymers in the soil helped to contribute to nitrogen use efficiency and mitigate nutrient leaching (Fragalà et al)³.

Mulch Films

Biodegradable mulch films made from biopolymers are used to cover soil in which crops are grown. These films help in weed control, moisture retention, and temperature regulation, all while reducing the need for chemical herbicides and irrigation. Unlike traditional plastic films, biodegradable mulches break down after the growing season, eliminating the need for removal and reducing plastic waste.

Controlled Release Fertilizers

Biopolymers are used to encapsulate fertilizers, allowing for the slow and controlled release of nutrients. This technology enhances nutrient use efficiency by plants, minimizes leaching losses, and reduces the frequency of fertilizer application, leading to lower environmental impact and reduced labor costs.

Seed Coatings

Biopolymer-based seed coatings are used to protect seeds from pests and diseases and to enhance their water retention capabilities. These coatings can also be engineered to carry additional nutrients or beneficial microorganisms, promoting healthier and more robust plant growth.

Planting Containers

Biodegradable planting containers made from biopolymers offer an eco-friendly alternative to traditional plastic pots. These containers can be planted directly into the soil, reducing transplant shock and eliminating plastic waste.

Water Retention Gels

Biopolymer-based hydrogels can absorb and retain a significant amount of water, which can then be slowly released to plant roots as needed. This is particularly useful in arid regions or during dry spells, as it reduces the need for frequent irrigation and enhances water use efficiency.

Pesticide and Herbicide Delivery

Similar to controlled-release fertilizers, biopolymers can encapsulate pesticides and herbicides, allowing for targeted delivery and reduced chemical use. This encapsulation can help minimize environmental contamination and reduce the exposure of non-target organisms to these chemicals.

Biodegradable Greenhouse Films

Greenhouses covered with biodegradable films made from biopolymers can maintain optimal growth conditions for plants. After their useful life, these films can be left to degrade in the environment, reducing waste and labor costs associated with their removal and disposal.

Bioplastic Tools and Equipment

Tools, stakes, nets, and other agricultural equipment made from biodegradable bioplastics reduce the environmental impact associated with the disposal of these items, offering a sustainable alternative to conventional plastics.

By leveraging biopolymers, the agriculture industry can significantly reduce its environmental footprint, improve soil health, enhance crop productivity, and contribute to a more sustainable food production system. The ongoing development and application of biopolymer technologies hold promise for addressing many of the current challenges faced by this sector.

The application of biopolymers in cooling towers is part of a broader trend towards greener, more sustainable industrial practices. By leveraging biodegradable, non-toxic materials, the cooling towers industry can reduce its environmental impact while maintaining or even enhancing system performance. However, the successful integration of biopolymers into cooling tower operations requires careful consideration of material compatibility, system requirements, and economic factors. As research and development in this area continue, it is expected that the use of biopolymers in cooling towers will expand, offering new solutions to old challenges.

In the cooling towers industry, biopolymers are increasingly recognized for their potential to improve water treatment processes and enhance system efficiency. While the use of biopolymers in this sector is not as widespread as in others like packaging, agriculture, or medicine, they offer innovative solutions for some of the key challenges in cooling tower operations. Here are the main applications of biopolymers in the cooling towers industry:

Water Treatment and Conditioning

Biopolymers can be used as environmentally friendly alternatives to traditional chemical treatments in cooling towers. They can serve as flocculants, helping to aggregate and remove suspended solids, organic matter, and microorganisms from the water. This process improves water clarity and quality, which is essential for maintaining the efficiency of cooling systems.

Scale Inhibition

Biopolymers have shown potential in inhibiting scale formation on cooling tower surfaces and heat exchange equipment. Scale, primarily composed of calcium carbonate, magnesium silicate, and other mineral deposits, can significantly reduce system efficiency and increase energy consumption. Certain biopolymers can bind to scale-forming ions, preventing them from crystallizing and depositing on surfaces.

Corrosion Inhibition

Some biopolymers exhibit properties that can help protect cooling tower metal components from corrosion. They can form a protective layer on metal surfaces or sequester corrosive agents in the water, thereby extending the lifespan of the cooling tower infrastructure.

Biofilm Control

Biofilms formed by bacteria and other microorganisms on the surfaces of cooling towers can lead to reduced heat exchange efficiency, increased corrosion, and health risks such as Legionella proliferation. Specific biopolymers have been identified that can disrupt biofilm formation or facilitate the removal of existing biofilms, enhancing system performance and safety.

Water Conservation

By improving the efficiency of water treatment and reducing the need for frequent blowdown (the process of removing a portion of the water to control concentration levels of salts and other impurities), biopolymers can contribute to water conservation efforts in cooling towers. This is particularly important in regions facing water scarcity challenges.

The use of sustainable water treatment biopolymers is not just a possibility -- it's a current reality. Biopolymers are finding their way into a number of industries and are being used to treat a wide range of problems, both with respect to water treatment and otherwise.

Whether it's scale deposition in oil and gas, boosting crop yields in the agricultural setting or other applications, like biomedical or packaging applications, biopolymers are truly a heroic macromolecule. There isn't much they can't do.

Going forward, use cases for biopolymers and, by extension, sustainable water treatment biopolymers, will only continue to grow.

Are you looking to implement sustainable water treatment practices in your business? Contact our Water Treatment team for more information and to learn more about Aspartyl and what Dober has to offer in the space of sustainable water treatment biopolymers.

REFERENCES

1. Muhammad Shahzad Kamal, Ibnelwaleed Hussein, Mohamed Mahmoud, Abdullah S. Sultan, Mohammed A.S. Saad, Oilfield scale formation and chemical removal: A review, Journal of Petroleum Science and Engineering, Volume 171, 2018, Pages 127-139, ISSN 0920-4105, https://doi.org/10.1016/j.petrol.2018.07.037 (https://www.sciencedirect.com/science/article/pii/S0920410518306120).

2. Xia S, Zhang L, Davletshin A, Li Z, You J, Tan S. Application of Polysaccharide Biopolymer in Petroleum Recovery. Polymers (Basel). 2020 Aug 19;12(9):1860. doi: 10.3390/polym12091860. PMID: 32824986; PMCID: PMC7564477.

3. Fragalà, F., Puglisi, I., Padoan, E. et al. Effect of municipal biowaste derived biostimulant on nitrogen fate in the plant-soil system during lettuce cultivation. Sci Rep 13, 7944 (2023). https://doi.org/10.1038/s41598-023-35090-y.