Yellow Metal Corrosion and How Azole Supplements Can Help

Yellow metal corrosion is probably something you've thought about a lot as a water treatment. In addition to other types of metals, critical parts of the cooling tower system include yellow metals, like copper, that are subject to corrosion under certain conditions. When copper or other metals corrode in your system, it will lead to:

- Downtime for repairs

- Increased costs that come with those setbacks

Understanding the causes, consequences, and preventive measures for this type of corrosion is crucial for ensuring the long-term performance and reliability of cooling tower systems.

By implementing proper water treatment, corrosion inhibitors, and maintenance practices, you can mitigate the adverse effects of yellow metal corrosion, thus prolonging the life of system components.

Yellow Metal Corrosion in cooling towers

So what are the repercussions of yellow metal corrosion in your cooling tower system?

-

Increased Maintenance Costs: Frequent corrosion-related issues necessitate more maintenance and repair work, leading to higher operational costs.

-

System Failures: Severe corrosion can lead to the premature failure of equipment, potentially causing costly downtime and safety hazards.

Preventing Yellow Metal Corrosion

-

Water Treatment: Implementing effective water treatment programs is essential to control the chemistry of cooling tower water. Regular monitoring and proper control of the water treatment chemistry will ensure that corrosion is controlled.

-

Corrosion Inhibitors: The use of corrosion inhibitors specifically designed for yellow metals can provide a protective passivation layer on metal surfaces, reducing their susceptibility to corrosion.

-

Regular Inspection and Maintenance: Conduct routine inspections to detect early signs of corrosion and address them promptly. Cleaning and descaling as necessary can help maintain system efficiency.

Yellow Metal Corrosion Inhibition with Azole Supplements

We've talked about the harmful impacts of yellow metal corrosion and ways to be proactive about mitigating it in your system. One of those ways is through the use of corrosion inhibitors like tolytriazole or benzotriazole (i.e., "azoles" for short)..png?width=400&height=250&name=CW42-SR%20Landing%20Page%20Graphic%20(1).png)

Think of it this way: azoles work by creating a protective coating, or passivation layer, to protect your yellow metals.

In other words, it's a chemical shield for your yellow metals.

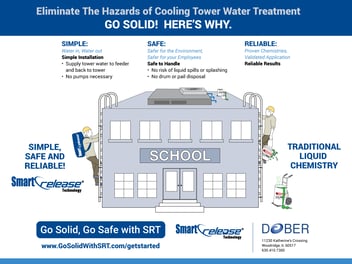

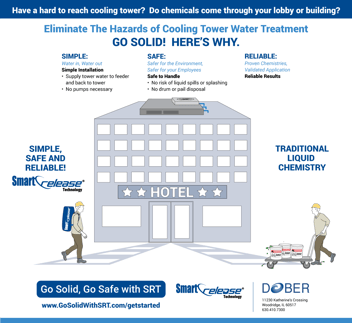

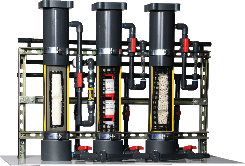

Dober's Smart Release Technology chemistry offerings include an azole supplement, CW42-SR, that gives you additional protection when required to increase your yellow metals protective shield.

The benefits of CW42-SR are many, including:

- Easy-to-use with Smart Release Technology

- Very low feed rate due to its highly concentrated form

- No chemical metering pumps are required

- Proven yellow metal corrosion inhibition chemistry

Want to Learn More About CW42-SR?

If you're looking to supplement your corrosion inhibition efforts, reach out to the Smart Release Technology team for more information about CW42-SR.

Your cooling tower system's yellow metals will thank you.