Non-Chemical, Other Alternatives for Cooling Tower Water Treatment

Cooling Tower Water Treatment Goals

The development of cooling tower water treatment focuses on three goals: preventing and eliminating scaling, corrosion, and microbiological growth.

Each presents its own unique challenge with respect to the effectiveness of water-cooling towers. However, those challenges are interrelated.

Scale

Scale is the precipitation of deposits from mineral salts in water. These precipitates settle in the cooling tower, which can stifle water flow, reduce the efficiency of heat transfer and lead to corrosion.

Scale can settle in openings created by corrosion, making parts of the system more difficult to reach and treat.

Corrosion

Corrosion is the dissipation of the metal in cooling towers due to chemical reactions with scale and bacteria. It reduces the life of your equipment, and can lead to accelerated damage via deposition.

Microbiological Growth

Bacteria and algae are easily able to grow in untreated cooling tower water because of the warm, wet environment. These bacteria can cause corrosion, and even lead to an outbreak of things like Legionnaires' disease, which spreads via Legionella bacteria.

These concerns are all interlinked and any of them can contribute to accelerated rates of negative effects associated with the others. Because there are so many factors to consider within cooling tower water treatment, a number of treatment options have developed over the years, each with multiple considerations and elements.

Traditionally, cooling towers have been treated with liquid chemistries. However, for the past few decades there has been a trend towards alternative treatment methods, such as solid chemical treatment and non-chemical water treatment solutions. You can learn more about the solid-feed Smart Release Generation 2 solution by downloading the free e-book below.

When To Consider Solid Cooling Tower Chemistries

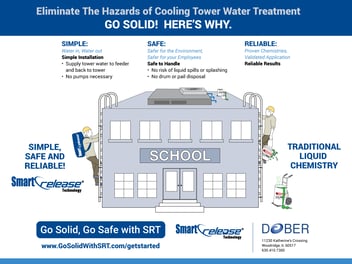

Solid-feed cooling tower water treatment programs leverage the same chemistries as liquids but are delivered and applied differently.

Where liquids delivered in drums or in bulk require a dock door or special delivery instructions, solids are often delivered via ground shipments in easy-to-handle boxes. Solids have the advantage of delivering more concentrated chemistries, which is an added benefit on your freight bill.

The handling and storage footprint of the solid programs often make it a very desirable solution in smaller, hard-to-reach cooling tower locations. Application of solid chemicals often falls into one of five categories:

-

Time-Release Tablets: Tablets are created from powders and then coated using similar technology to time-release pharmaceutical capsules. Instead of releasing over 12-24 hours, the tablets release over a period of 30 days to match up with a common frequency of service visits.

-

Time-Release Granules: Some chemistries cannot be tableted, so their release is controlled by membranes designed to match the particle distribution of the chemical granules.

-

Uncoated Tablets: Uncoated tablets will release immediately but can be controlled by managing water flow rates.

-

Paste: The fourth option of a solid program also leverages the benefits of concentrating the chemicals; instead of a granule or tablet, it is delivered in a paste-like form. As water is sprayed onto the paste, it dissolves into a liquid and is released into the system.

By selecting chemistries proven to successfully treat scale, corrosion, and microbial growth, you will have peace of mind that your water treatment strategy is off to a good start.

Why would you consider non-chemical water treatment for your cooling tower?

Because chemical treatments are the traditional water treatment method, one might wonder why stray from what is tried and true.

The main considerations for using non-chemical approaches fall under the umbrella of aiming to reduce the associated carbon footprint. Non-chemical treatments can reduce your carbon footprint by avoiding the bulky packaging, disposal, transportation, and spillage of traditional liquid chemical treatments. Liquid chemicals also require storage space for the chemicals, the systems and spill containment preparations.

One approach to mitigating these problems associated with liquid chemicals is non-chemical treatment, which has its own set of benefits and complications.

What are the primary methods of non-chemical treatment?

The current approaches of non-chemical treatment include:

1. UV light (Scaling, Microbiological Growth)

Water passing through cooling towers is exposed to UV light through special mechanical equipment. This UV light has the ability to scramble DNA of microorganisms and kill them.

2. Ozone (Microbiological Growth)

Ozone is a compound with three oxygen atoms. It degrades into oxygen, freeing one oxygen atom that is highly reactive. This decomposition picks up iron, manganese and hydrogen sulfide, effectively filtering the water and creating solid compounds (which then must be filtered out of the water). Ozone also acts as an oxidizing biocide, killing bacteria in the water.

3. Copper Ionization (Microbiological Growth)

Also known as magnetism or electrostatic treatment, copper ionization uses a low-voltage electrical current to release copper ions into the water. Copper ions reduce microbial growth and bind with hardness minerals to reduce scaling.

4. Electrodeionization (Scaling)

Electrodeionization, or EDI, uses an electrical charge to separate compounds in the water into cations and anions. When they have reached their ion state after separation, they are able to pass through a semipermeable membrane to be separated from the rest of the water in the cooling tower. This prevents the buildup of minerals in the system and on the equipment.

5. Pulsed-Power (Scaling, Microbiological Growth)

Pulsed-power water treatment uses stored energy to emit brief and consistent high-frequency pulses to the system. This charge recasts the minerals in the water as a preventative measure of scale conglomerating. Meanwhile, the electricity kills bacteria — reminiscent of the technology’s original use in pasteurizing foods.

6. Electrochemical Deposition (Scaling, Microbiological Growth)

There are several approaches to electrochemical decomposition, but they all reduce scaling and microbiological growth. The major techniques in this category include electrochemical oxidation, electrochemical reduction, electrocoagulation, electroflotation, and electrodialysis. The most efficient method for a particular system will be based on the composition of the water in the system.

Corrosion is minimized with the reduction of scale and bacteria. So, indirectly, all of these options help reduce corrosion.

And though there are several goals of water treatment, each non-chemical option addresses only a limited array of those goals effectively. Therefore, non-chemical treatment options need to be applied in combination, with different cooling tower systems requiring different algorithms.

Challenges with Non-chemical Treatments

While non-chemical treatments have their own unique benefits, non-chemical treatment options also have obstacles to be considered when making the right choice for a specific cooling tower water treatment system.

The biggest obstacle is the intricate and specific design of treatment programs. Because no treatment type directly addresses scaling, corrosion, and microbiological growth simultaneously, a combination must be applied. Then, because of the specific equipment fittings and installations required for these treatments, plans must be calculated correctly and exactly.

You must also consider water hardness when choosing non-chemical treatment regimens over chemical treatments. For the most effective applications of non-chemical alternatives, water must be pre-filtered before entering the system. Post-filtration may also be necessary. For ozone to bind with manganese, hydrogen sulfide, and iron to prevent scaling, additional filtration for these solids after they are bound with the oxygen ion is required.

Because of all this additional filtration, in regions where the water is notably hard, the additional expense, equipment, and ineffectiveness may not be worth the cost of installing non-chemical treatment options. In fact, 85% of the U.S. has hard water: However, some areas, like Maine, Oregon, and Mississippi, would be more likely to receive higher levels of efficiency with non-chemical treatments.

Another factor to consider is that non-chemical approaches to microbiological growth revolve around treatment, rather than prevention. For example, the bactericidal effects of copper-silver ions, while well documented, kill bacteria rather than inhibit it. Meanwhile, chemical approaches both kill and inhibit bacteria, acting as both prevention and a treatment method. Therefore, non-chemical approaches may be better used in a system that is not already experiencing unmanageable microbiological growth.

The Importance of a Good Service Representative

As with all water treatment, it is of the utmost importance to recruit a knowledgeable and reputable sales representative (Dober can connect you with a distributor).

Liquids, solids and non-chemical cooling tower systems all have a place in the industry. One or more of those options may be a good fit for you.

But no matter how well a chemical or non-chemical program is designed, it will be incomplete without a highly trained service representative.

Summary of Alternatives to Liquid Cooling Tower Water Treatment

The recipe for creating a strong water treatment program hasn’t changed: develop water treatment goals and select a water treatment professional that can help deliver those goals.

What has changed is that there are now more viable options for achieving the goals. Careful consideration of your goals, strategy and execution plan will help you achieve your water treatment goals.