The "water" in "cooling tower water treatment" does the heavy lifting in many cooling processes.

Due to water’s high heat capacity and ability to evaporate naturally, it is the most efficient conduit of energy transfer and has many unique advantages when used in cooling processes, such as: cooling towers, chillers, plate and frame heat exchangers, shell and tube heat exchangers, and many more.

In fact, water has been used in mechanical cooling processes starting as early as the 18th century, when it was used to improve the efficiency of steam engines. Water has many advantages in the cooling process.

However, water treatment for cooling towers is about more than just water. There are a host of other challenges to consider, including corrosion, mineral scale, fouling and microbiological contamination.

These disadvantages can be managed and avoided with proper mechanical, operational and chemical treatment methods.

It is absolutely critical when managing water-based cooling equipment to not only be aware of these potentially destructive side effects but also know how to avoid and properly manage them. Proper management of a cooling tower, chiller, or other water-based cooling equipment can be broken down into three main components:

-

-

Mechanical – installing the proper equipment for your process and utilizing pretreatment greatly reduces the risk of breakdowns and unnecessary chemical requirements.

-

-

Operational – operating and maintaining your equipment to manufacturer recommended guidelines.

-

Chemical – the final component that is used to “polish” and improve system performance and should never be used in place of proper mechanical and operational measures.

Here, we will focus on chemical treatment as it functions as part of a robust cooling tower water treatment program. Chemical treatment, while not the first line of defense, is critical to running a clean, efficient cooling system.

Mineral scale, which often presents in the form of calcium carbonate, is chemically controlled via scale inhibitors such as phosphonates and dispersing polymers. Corrosion is chemically controlled via corrosion inhibitors such as azoles, ortho-phosphate, poly-phosphate and molybdate. Fouling is chemically controlled via dispersant polymers.

Smart Release Technology has unveiled a cooling tower water treatment solution that utilizes innovative solid chemistries and equipment to give users an option that offers the best of both worlds of cooling tower chemicals (i.e., liquids and solids).

Interested in learning more? Download our Smart Release Generation 2 e-book below to learn more about what's possible in your cooling tower water treatment program.

What do cooling towers do? Furthermore, what does an effective cooling tower water treatment program entail?

Before venturing into the types and use cases of cooling towers and cooling tower water treatment programs, it's important to understand, at least on a big-picture level, what they do for us on a daily basis.

The impacts of cooling tower water treatment in our daily lives are many. In a nutshell, cooling towers transfer heat safely from inside an active system to the outside environment, which you'll often see in the form of a billowing mist.

Put it this way: different species have different ways of achieving their cooling needs. Dogs, for example, cool down by panting. Humans cool down through the process of perspiration.

In a sense, that is what a cooling tower is doing: perspiring and expelling excess heat out of a system. In this case, rather than the human body, substitute for a hospital or data center, for example. .png?width=400&height=300&name=SRT-Cooling-Tower-Uses%20(1).png)

When you think about it, cooling towers impact nearly every major aspect of our lives: our work, our health and many of our daily needs.

You'll find cooling towers anywhere you need significant process cooling, which can include places like hospitals, schools, hotels, manufacturing facilities and much more. As the Centers for Disease Control and Prevention notes, cooling towers are used primarily for heating, ventilation and cooling (HVAC) and industrial purposes.

Without safe and effective cooling tower water treatment at all of these important sites — where we receive health care, where our kids go to school, where our food and other important things get manufactured — you risk equipment failures or, worse, potential illness among those near the system in question.

While cooling tower technology has certainly evolved, it has been around for quite some time.

Dutch engineers Gerard Kuypers and Frederik van Iterson developed the first hyperboloid cooling tower in the early 1900s. Kuypers filed a patent in 1917 for a "cooling tower of reinforced concrete." So, the understanding that excess heat must be removed from a variety of industrial systems is not a new concept.

Of course, the chemistries involved in cooling tower water treatment have evolved over the years as water treaters have gained a greater understanding of the types of things that need to be protected against, including scale, corrosion and microbial growth.

Water treatment for cooling towers is vital to the safe and effective management of your cooling tower system.

As such, it's important to speak the language of cooling tower water treatment. We know cooling tower water treatment is important and why it's important, so let's dive into the lingo of cooling tower water treatment and take that understanding to the next level.

As such, we've compiled a list of some key terms for cooling tower water treatment. With that said, this is not an exhaustive list; cooling tower water treatment is a complicated and delicate science, so there are many more concepts worth understanding.

Alkalinity

Alkalinity — or M-Alkalinity — is an important measurement for your cooling tower water treatment program of the amount of carbonates, bicarbonates and hydroxides in your process water.

Generally, you want your cooling tower process water on the alkaline side; however, if it is too alkaline, you can get deposition of scale (e.g., calcium carbonate). That's why cooling tower water treatment programs often include pH adjusters to bring pH down to optimal levels as needed, particularly as alkalinity levels increase as cycles of concentration increase.

Biocides

Biocides are vital to any effective cooling tower water treatment program. Cooling towers offer a welcoming environment for microbial growth; if bacterial growth within the system is present, it could lead to fouling (see "Fouling" below), decreased efficiency and distribution of bacteria via aerosols that could lead to illness if inhaled. Perhaps the most well known example of this is Legionnaires' disease.

So, biocides are the chemicals that mitigate and prevent microbial growth in your cooling tower system. These chemicals can be delivered in liquid or solid forms.

Blowdown

Blowdown is the water flushed out of the system due to higher levels of mineral concentration. Simply put, the more cycles of concentration you can get out of your system, the more you save on water in the form of make-up water (see the "Make-up" entry below).

Blowdown also includes leaks, drift and windage.

Cooling Tower Basin

The cooling tower basin is where cooled process water is collected before it is recycled in the system.

Corrosion

As with many industrial processes, corrosion is a cause for concern in the cooling tower system. Contaminants in the cooling tower system can lead to corrosion of various surfaces within the cooling tower. As a result, the heat-transfer capacity of the system and its efficiency declines.

Counterflow

A counterflow cooling tower is a type of cooling tower in which air flows counter to the direction of the process water.

Crossflow

Meanwhile, a crossflow cooling tower is a type of cooling tower in which the air moves horizontally with the direction of the process water.

Cycles of Concentration

This term is one of the most important in the world of cooling tower water treatment. To calculate your cycles of concentration, you need to determine the ratio of dissolved solids in your blowdown water relative to your make-up water.

"From a water efficiency standpoint, you want to maximize cycles of concentration," the Department of Energy explains. "This will minimize blowdown water quantity and reduce make-up water demand. However, this can only be done within the constraints of your make-up water and cooling tower water chemistry. Dissolved solids increase as cycles of concentration increase, which can cause scale and corrosion problems unless carefully controlled."

Drift

While much of the heat transfer in the system occurs via evaporation, some water is carried out via "drift," or by a mist or small droplets. Windage can be a contributor to drift.

"Drift loss is small compared to evaporation and blowdown and is controlled with baffles and drift eliminators," the Department of Energy notes.

Evaporation

The process by which most heat is transferred out of a cooling tower system.

Fill

The cooling tower "fill" area is the surface on which the heated water is distributed as it enters the cooling tower system. From there, air contacts the water and heat is expelled from the system via evaporation.

Fouling

Fouling is the general term for when material builds up and/or deposits on cooling tower surfaces, thus impacting the system's heat-transfer capacity. In addition to scaling, fouling is often referred to in the form of microbiological fouling, which is when microbial growth occurs within the system.

Cooling towers provide a welcoming environment — warm and wet — for microbial growth, which is why your cooling tower water treatment program must address the issue with the use of effective biocides.

Heat Load

Heat load, measured in BTUs per hour, is the amount of heat that needs to be removed from the cooling tower process water. Heat load is an important parameter in determining tower size and cost.

To determine heat load, multiply gallons per minute by 500 and by the temperature delta of cold water from the cooling tower and hot water going into the system. The formula is also written out below:

Heat load=GPM x 500 x ΔT

Make-up

This term is related to the "blowdown" term above. Make-up water is exactly what it sounds like: it's the water used to make up for the loss in "blowdown" water.

In general, cooling tower water treatment seeks to make a more efficient process that leads to less need for make-up water. In short, an environmentally conscious and more sustainable process would call for less water.

As the Department of Energy explains, make-up is equal to the sum of blowdown, evaporation and drift in the system. However, as noted previously, when cycles of concentration increase, so does alkalinity and, in turn, the possibility of scaling.

pH

In most cooling tower systems, you will typically see a pH level of anywhere between 7.0-9.5. However, some systems do run outside of that range (i.e., more acidic or more alkaline). You don't want your process water to be too acidic, as that can lead to corrosion of various surfaces. However, if your process water is too alkaline, that can promote the formation of scale. Alkalinity in the water increases as evaporation occurs, meaning a rise in pH.

Scale

When water is evaporated out of the system, remaining levels of solids can coat surfaces of the cooling tower, i.e., scale. What does that mean for the system and your cooling tower water treatment needs? Deposition of scale can negatively affect the heat-transfer capacity of the system.

Furthermore, deposition of scale can also provide opportunity for microbial growth.

In order to combat scale, you need scale inhibitors in your cooling tower water treatment program.

Tons

Terms used to express the capacity or size of the cooling system. One ton is equivalent is equivalent to 12,000 BTU per hour.

A ton of refrigeration represents the rate of cooling produced when a ton of ice that weighs 2,000 pounds melts during a 24-hour day.

TDS (total dissolved solids)

Total dissolved solids represents the total amount of inorganic and organic molecules in the cooling tower process water. Those solids could include things like calcium, magnesium, silica and chloride, among others. Calcium carbonate is the most commonly found scaling deposit in the cooling tower system.

In short, you don't want your TDS to get too high.

Think of a swimming pool. You and your family and friends are enjoying some time in the pool. There are a few pool toys floating around in there: a pool noodle or two, maybe a floating pool chair, a couple of smaller toys for the younger children. Bottom line, there's room for you to move around and enjoy the space offered by the pool.

Now add, say, 30 more pool noodles, 20 more pool chairs and a flock of rubber ducks. There isn't as much space to move around and your pool experience isn't quite as enjoyable if you're constantly maneuvering around these various obstacles. Not only that, maybe all that flotsam and jetsam finds its way to the pool skimmers and drains, covering or clogging them up. If that happens — and you don't take time to address the problem — the pool system won't be able to effectively circulate clean, safe water for you to swim in.

Meanwhile, if TDS gets too high in your cooling tower system, that means those solids could lead to corrosion, deposition of scale and microbial growth. That, in turn, contributes to lower heat-transfer capacity and a less efficient system.

Water Balance/Mass Balance

Your make-up equals evaporation plus blowdown.

Windage

Water lost from the cooling tower system when winds blows water droplets out of the cooling tower.

LIQUIDS VS. SOLIDS

We've reviewed the basics of cooling towers and cooling tower water treatment: what a cooling tower does, why you need a robust cooling tower water treatment program and some of the basic key terms and metrics to consider when implementing such a program.

But what about the chemicals you're feeding into your system?

Like most consumer scenarios, there are options to consider. The main options are liquid versus solid chemistries for cooling tower water treatment.

Liquid Chemistries

All-liquid cooling water programs have been prominent in the cooling tower water treatment industry for years, given it has been the norm for professional water treaters and customers alike.

As with any industry, change can be something many managers might not want to consider. "If something is working just fine, for the most part, why change it?" a property manager might say (or, more colloquially, "if it ain't broke, don't fix it").

That is an understandable perspective, as there can be costs associated with changing any process. In general, liquid chemicals do work effectively in the context of cooling tower water treatment.

Furthermore, with a liquid program, cooling tower engineers can have control of their chemical delivery. That means not having to deliver chemicals at all times, but rather only when the system requires additional treatment.

Solid Chemistries

As noted, there is a solid-based alternative to the aforementioned liquid option.

While solid water treatment programs are not currently as widespread as liquid programs, they are becoming increasingly popular.

Here's a quick video showcasing how Dober's solid-based chemicals work:

So what are some benefits of the alternative for cooling tower water treatment?

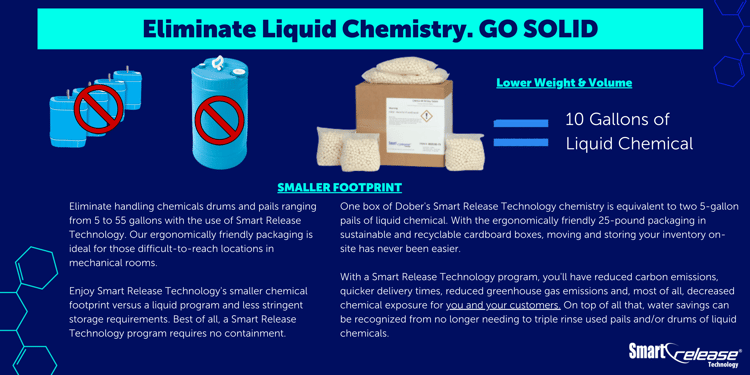

Safety

Solid programs are generally safer for personnel. With solids, personnel have reduced exposure to harmful chemicals (as compared with liquids). Furthermore, solid chemistries are easier to transport on-site by personnel. To put it in perspective, one box of Smart Release Technology is equivalent to two five-gallon pails of liquid chemicals. That means fewer injuries related to moving pails and drums, not to mention potentially even more serious injuries associated with direct exposure to liquid chemicals.

NO SPILLS, LEAKS

Users don't have to worry about the spills and leaks that can happen with liquid programs.

more Environmentally Friendly

Unlike liquids, Smart Release Technology tablets can be disposed of in regular trash pickup. Meanwhile, liquid pails and drums need to be triple rinsed before disposal (of course, local regulations can vary, so users should always check to make sure they are complying with regulations associated with chemical disposal).

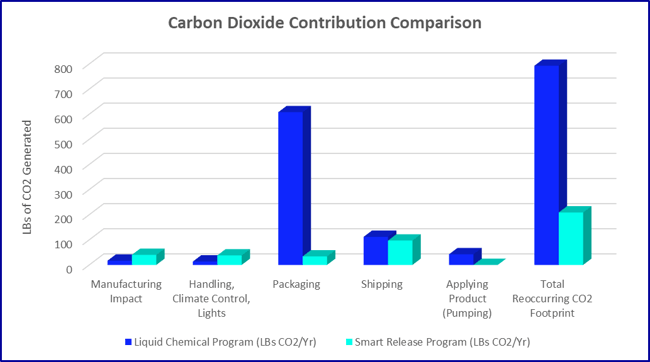

In addition, you will generate a smaller carbon footprint with solid-based chemistries in a number of ways. The chart below outlines some of those CO2 differences:

Data source: Mosher, Steve. Environmental Aspects of Controlled-Release Chemistry in Cooling Towers. [White Paper]. Smart Release Technology.

NO CHEMICAL METERING PUMPS

With Smart Release Technology's solid-based cooling tower water treatment solution, users don't have to worry about managing chemical metering pumps.

Easier Storage

Unlike liquid chemicals, Smart Release Technology's solid-based chemistries do not require special containment.

At the end of the day, each cooling tower is different. In turn, each cooling tower water treatment program will be different and adjusted for the site's specific conditions, water content, cost, the treatment team's personal preferences and history, and a number of other factors.

While a liquid program might ultimately suit a site better at a given time, a solid program might be the preference of another site.

With that said, there are important differences between the two program types, as laid out above.

If you've gotten this far, thank you for your time and dedication. Maybe you're a cooling tower water treatment industry professional and are looking to explore your options toward the goal of getting the most out of your treatment program. Or, maybe you're an executive at a site with significant cooling tower applications and want to explore other options for your school building, data center, hotel, etc.

We get it: there are always efficiencies out there waiting to be gained. You just have to know where to find them.

Here at Dober, we're passionate about Smart Release Technology and solid-based treatment solutions. We believe that our combination of solid chemistries and innovative equipment gives you the best of both worlds: the liquid benefits you might already be used to (e.g., control of chemical delivery) and the benefits associated with solids, like safety, lower carbon footprint, easier handling and storage, and much more.

We have continued to innovate, most recently with Smart Release Generation 2 (you can check out our latest case studies, which outline how one traditional Smart Release customer got extended tablet life with their system, while another harnessed the power of daily reporting to reduce microbiological fouling).

Interested in learning more? We're waiting to hear from you.

Reach out to us and a Smart Release Technology expert will be happy to walk you through the benefits of a solid-based cooling tower water treatment program.