Recycled Antifreeze Blenders

Technological advancements in coolant chemistry supports efforts to reduce the environmental impact of frequent drain and refill intervals. The environmental impact of serviceable fluids such as antifreeze and lube oil are driving a healthy industry devoted to recycling these fluids in a responsible manner.

High quality recycled antifreeze products are produced only by reclaiming the glycol (freeze point depressant) and stripping all contaminants and residual corrosion inhibitors from the glycol. Glycol or glycol/water mixture is then used as a raw material to formulate an engine coolant that can perform as well as virgin products.

Although free markets offer lots of competition, there will always be variation in the quality of products and producers in a particular market. For example, a product that is reportedly made from “virgin” materials may not meet industry specifications and may have questionable performance. The true question of quality is the responsibility of individual companies to ensure its products are quality compliant.

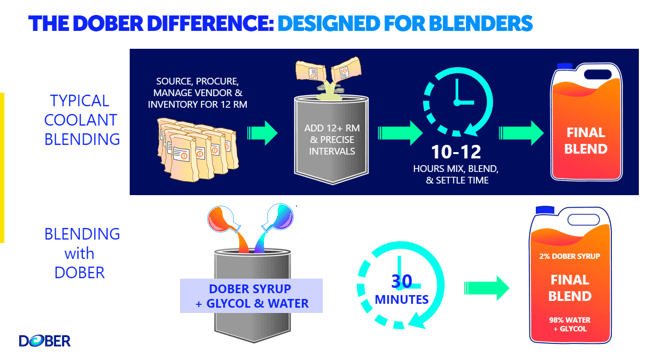

Dober offers coolant chemistry and additive technology to recycled antifreeze blenders, which ensure compatibility with other coolants throughout the recycling process. Our highly concentrated Super Syrup coolant additives, coupled with blending procedures help blenders produce quality products with consistent mixing of formulas backed by extensive research, development and testing.