How to Tell if You are Using the Wrong Detergent

One of our top goals with Chematic® at Dober is to provide our customers with the optimal detergent and cleaning process to remove their difficult residues.

However, we know it may not always be obvious that the detergent you are using is ineffective, or that there may be better options out there for your process. This is especially true when using a legacy cleaning agent that has been in your facility for years, where the age-old adage, “if it isn’t broken, don’t fix it” is often applied.

Developing effective cleaning processes is a crucial part of quality control. Use of an ineffective process or cleaning agent can lead to batch contamination and failures. Why not remove this risk to your product’s integrity by making sure you are cleaning the right way from the start?

We have listed some scenarios below that may be an indication that your detergent could be working better for you.

How We Replicate Your Process >

-

Residues redeposit or settle out of solution.

Ideally, the detergent you select would completely break down and dissolve the soils you are trying to remove. Due to advanced formulations using insoluble materials, we know that this is not always possible. However, your detergent should suspend and emulsify these components so that they remain suspended in your detergent solution and can be effectively flushed away with your final rinses. If you find that your detergent frequently leaves materials that settle out at the bottom of your equipment while draining, or you notice that residues redeposit further down the equipment train in areas that were previously unsoiled — including your CIP system itself — this may be an indication that your detergent is not effective at suspending or emulsifying the products you are trying to clean.

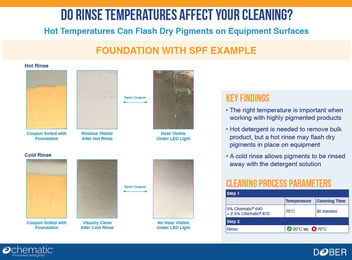

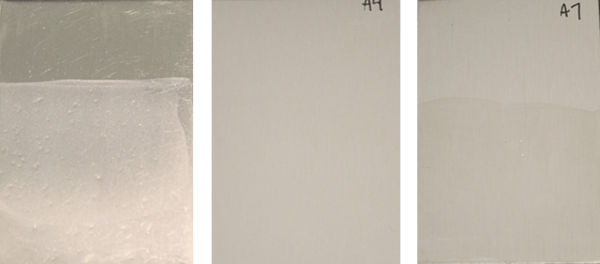

These photos show a beaker of detergent solution that does not properly suspend the soil. Flakes of product are visible floating on top of the solution. These flakes redeposit back onto the coupon surface when it is removed from the beaker. With the correct detergent, there are no flakes or unsuspended materials, resulting in a clean surface.

-

Recleaning the same equipment multiple times before passing results can be obtained.

If the correct detergent is used, the number of cleaning passes over the same part of the equipment train should be minimized. While the need to refresh detergent solutions to increase the saturation limit is typical, repeating your entire cleaning process multiple times in order to achieve a passing result is not. Examples of these inefficiencies may include having to perform a manual scrub or wipe-down after an automated cleaning cycle or multiple rounds of soaking and scrubbing the same piece of equipment. A detergent that is targeted specifically for the residue you are trying to remove will work better the first time, reducing the need for reapplications. We recommend taking advantage of the Chematic® CCE process to help identify the detergent targeted for your specific soils.

-

Sudden Microbial or Swab Failures

If residual or microbial swab testing begins to fail after several “successful” rounds of campaigned production and cleaning, there may be an issue with your detergent. This is an indication that the current cleaning product may be leaving behind a hidden residue that is difficult to detect. These residues are common in products containing viscosity modifiers or film formers. While initially missed, they have the potential to build up to detectable or visible limits over time and can be a food source for microbial contamination. Cleaning with the proper detergent will ensure that all residues, even those that are difficult to see, are completely and consistently removed, eliminating the risk of failures as production continues.

The photos below show a stainless steel test coupon that has been soiled with an SPF Moisturizing Lotion. When cleaned with the wrong detergent, the surface initially looks clean, but after multiple rounds of soiling and cleaning the same surface, a layer of residue becomes apparent.

View our article to learn more about detecting and combating hidden residues. -

Safety concerns with Disposal and Operator Handling.

It is common for legacy cleaning agents to be very highly alkaline or contain very high levels of solvents. Detergents of these types are often above regulatory limits for disposal to municipal water systems. They can require an additional neutralization step, or costly removal and disposal services. There are also concerns for the safety of the operators handling these materials. New technologies allow for Dober to create targeted cleaning agents that are just as, if not more effective at cleaning with friendlier components that are milder in pH, contain no solvents, and have surfactants that are more easily biodegradable.

Just because you can get your current cleaning agent to work, that doesn’t mean it's working the best for you. Ensuring that you have a detergent that is right for your particular products and processes not only helps ensure the quality of your product but can also reduce downtime and increase production capacity. Contact Dober to see which Chematic® detergent will be right for you.