A Better Alternative to IPA Cleaners

With the rapid development in Pharmaceutical, Nutraceutical & Personal Care formulations, newer and more complex excipients, as well as actives, are processed together, most of which are not soluble in water but dissolve in one or the other organic solvent.

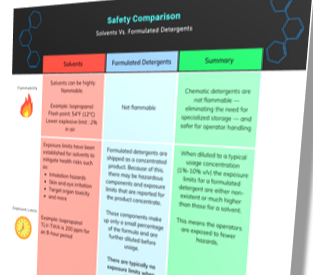

Although many solvents are considered for use in equipment cleaning by the industry, Ethanol, Acetone, and Isopropyl Alcohol (IPA) are most commonly used due to their comparative safety over other organic solvents, and the wide range of products that they dissolve. These solvents are also easily available to public consumers for personal use. The advantages of using solvents for residue cleaning include the solubility of residue, easy removal of solvents from the equipment surface due to volatility, and decreased chances of microbial growth & contamination. However, due to the known disadvantages of the use of solvents, the industry is moving towards other alternatives such as aqueous cleaning detergents.

"However, due to the known disadvantages of the use of solvents, the industry is moving towards other alternatives such as aqueous cleaning detergents."

A good example of such a case is the use of IPA for cleaning of cannabis oil in the Nutraceutical Industry. The world is opening up to the benefits of the CBD/Hemp oil-based products and as the demand grows, so do the manufacturing concerns, one of them being the cleaning of the sticky oily residue. Without a better alternative, the CBD/Hemp oil manufacturing and processing industry mainly relies on IPA to get rid of this tacky scum. While IPA does the job, it does not come without safety risks.

Risks Associated with IPA Cleaners:

- As listed in the SDS (Safety Data Sheet) document, Isopropyl alcohol is highly flammable with a Flash Point of 54°F (12°C) and a lower explosive limit of 2% in air. This warrants the use of proper PPE & engineering controls such as fume hoods and trunks, and yet, there is a risk, even after taking the required precautions. More times than not, this consideration isn’t even extrapolated to cleaning activities, increasing the danger of accidents

- The main safety hazard with IPA is that it is easily put into a vapor state from its normal liquid state. This means that the personnel cleaning a piece of equipment is easily exposed to the IPA vapors, which are highly hazardous. The ACGIH & NIOSH/Guide, found in the SDS for IPA, states that the threshold limit value (level to which a worker can be exposed day after day for a working lifetime without adverse effects) for IPA is 200ppm for an 8-hour period, equivalent to inhaling all of the vapors of 0.25 µL of IPA, which is far lower than what one would be exposed to in reality while cleaning!

- The toxicological values (LD50 Rat) based on the oral route for IPA are 2.5 to 5 times the toxicological values for the surfactants found in the formulated detergent.

While the safety reasons of solvents should be more than sufficient to consider alternate methods to clean, other disadvantages are:

- The complete formulation residue may not be soluble in the cleaning solvent (eg. Pigments).

- The residue has the potential to redeposit on surfaces as the solvent evaporates.

- Environmental issues associated with solvent-based cleaning processes can be significant. Discharging large amounts of cleaning solvents may be an issue with corporate and community images. Also, spent organic solvents are usually either recovered or incinerated, thus adding to the overall cost of manufacturing.

- Varying effects of the solvent on different surface types must be considered as solvents may react, soften and/or dissolve non-SS parts like pipes, gaskets & O-rings that are cost-incurring and at times, potentially dangerous for batch, equipment, facility, and manpower safety.

A Better Alternative to IPA Cleaners

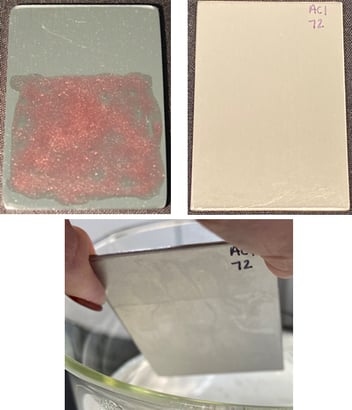

At Dober, we strive hard to find and fulfill the Industry cleaning requirements. Revisiting the example of the CBD/Hemp Oil cleaning, a new Chematic® Formulated Detergent was developed for cleaning residual CBD and Hemp Oils from various surfaces for the Cannabis Industry, in response to manufacturers requesting to replace the use of an organic solvent, isopropyl alcohol (2-propanol).

The Chematic® 420 & 420 HD cleaning agent is aqueous-based and consists of several components that target residual CBD/Hemp Oils and other residues associated with enhanced CBD/Hemp Oil formulas without the safety and toxicity concerns of IPA.

- Being aqueous-based, Chematic® 420 & 420 HD, and other formulated detergents are non-flammable and have a lower risk of inhalational exposure.

- Chematic® 420 is non-hazardous.

- All the information listed in the SDS for each component of Chematic® 420 HD is based on 100% of the component. However, it has to be considered the components are present in small quantities in the detergent and that the detergent is typically diluted to a 5% - 10% concentration of the bulk solution using water as the diluent.

- Chematic® 420 is not considered to be an aquatic toxin. As for Chematic® 420 HD, based on its SDS, although most of the surfactants used in any industrial or consumer cleaning are an aquatic hazard to some degree, we ensure that environmental safety is a consideration during our detergent formulation.

- Chematic® detergents are designed to hold the residue and associated insolubles within itself to avoid re-deposition

- This detergent is compatible with most of the equipment MOC and surfaces such as epoxy flooring.

A total shift from traditional cleaning methods will take time, but an aqueous detergent alternative is always preferable to an organic solvent option for the safety of the environment, personnel, and the facility, especially if it has all the benefits and none of the hazards associated with solvents.

If you are interested in learning more about how Chematic can help solve your challenges, we'd love to talk!