How to Clean Cannabis Residues

Cannabis residues can be cleaned with the right, solvent-free cannabis cleaner

CLEANING CANNABIS RESIDUE CAN BE CHALLENGING

Cannabis residues are known to be tough to clean, mainly due to the multiple oil-based, organic, and other water-insoluble components present in them.

Right from the cannabis cultivation and harvesting facility to the CBD/Hemp oil processing plants, cleaning of the resinous, oily, waxy, and sticky cannabis residue is a painstakingly difficult job with traditional cleaners or cleaning methods. Multiple approaches have to be adopted for cleaning different surfaces that are either not efficient or could be hazardous for the workers, facility, or the environment.

Wouldn't it be great if there was a cleaner that was safe, water-based, efficient, and worked on all surfaces? A cleaner that cleaned the stubborn soils with a simple swipe, without the need to scrub or use multiple cleaning steps? A cleaner that was suitable for manual cleaning and effectively with an automated cleaning process?

A Safer Cannabis Cleaner

The most common cleaning method employed to clean Cannabis and related residues is by using solvents, especially Isopropanol. Although this solvent makes the cleaning job very easy and it doesn't need rinsing due to its volatility, there is a whole list of safety concerns due to which the industry is moving towards other alternatives such as aqueous cleaning detergents.

- Isopropanol (IPA) is highly flammable with a Flash Point of 54°F (12°C) and a lower explosive limit of 2% in air. This warrants the use of proper PPE & engineering controls such as fume hoods and trunks, and yet, there is a risk, even after taking the required precautions. More times than not, this consideration isn’t even extrapolated to cleaning activities, increasing the danger of accidents.

- IPA is easily put into a vapor state from its normal liquid state. This means that the personnel cleaning a piece of equipment is easily exposed to the IPA vapors, which are highly hazardous.

- Environmental issues associated with solvent-based cleaning processes can be significant. Discharging large amounts of cleaning solvents may be an issue with corporate and community images. Also, spent organic solvents are usually either recovered or incinerated, thus adding to the overall cost of manufacturing

- Varying effects of the solvent on different surface types must be considered as solvents may react, soften and/or dissolve non-SS parts like pipes, gaskets & O-rings that are cost-incurring and at times, potentially dangerous for batch, equipment, facility, and manpower safety

Chematic® 420 being aqueous-based, is non-flammable and has a lower risk of inhalational exposure. At Dober, environmental and operator safety are main variables we take into considerations when we develop formulated detergents. Additionally, this detergent is compatible with most of the equipment MOC (Material of construction) and surfaces such as epoxy flooring.

Harvesting tools need to be cleaned properly

Whether you are working with trimming scissors or pruning shears, maintaining the blades is crucial for clean and accurate cuts during harvesting. The resinous residue easily gums up the blades and could dry up into something that would take a lot of trouble to clean, and potentially result in blunting the tools.

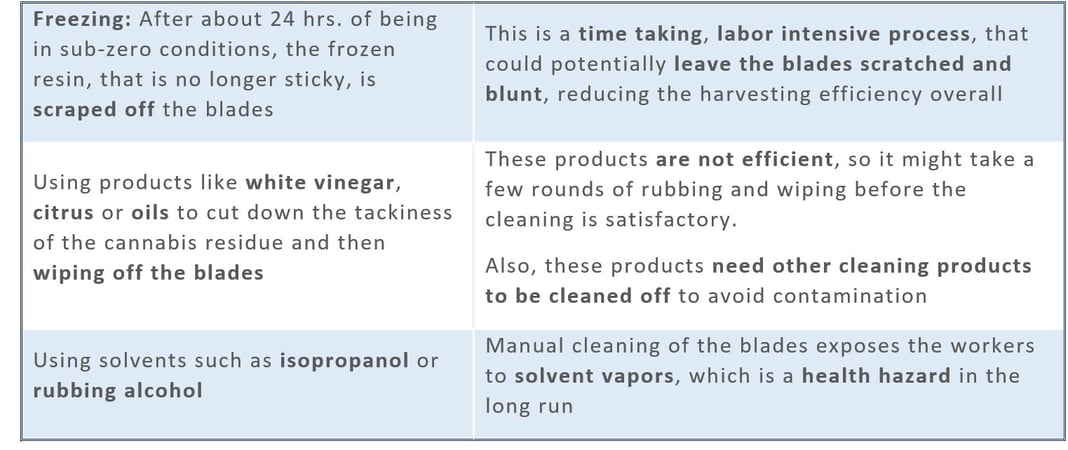

There are multiple traditional cleaning options, but each of them come with their own problems.

Chematic® 420 can be used at different concentrations to soak and easily wipe off the tools and it is to be followed up by water rinsing. It can also be used in ultrasonic cleaners or parts-washer for cleaning multiple tools at once.

Cleaning of Harvesting & Processing Accessories & facility made easier

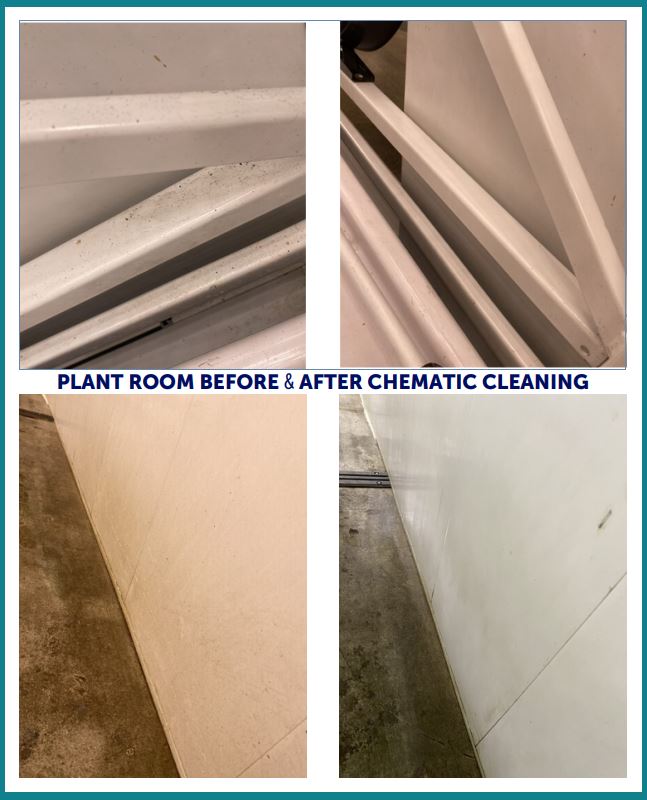

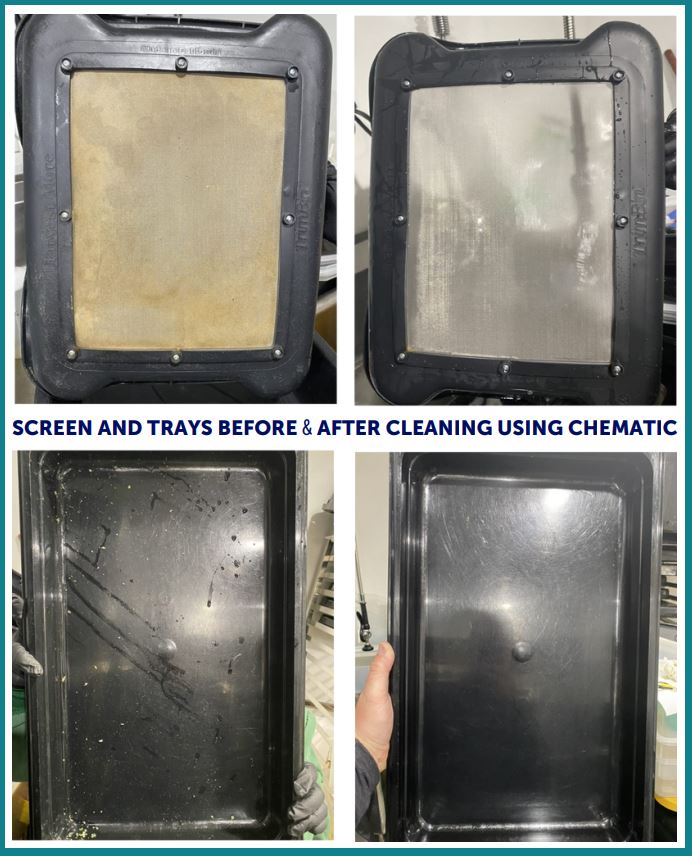

Beakers, trays, racks, screens, storage bins, nursery tables, and any other accessories that come in contact with the cannabis plant and its residues would need to be cleaned thoroughly to prevent contamination, pests, and pathogens. The same stands true for the facility in general, including the walls and floors of nursery, plants, trimming, and drying rooms.

Depending on the size of the accessory or room to be cleaned, the area needs to be wetted with the cleaning agent using a spray bottle or an application spray system and wiped out with scrub pads, brushes, or mops. Final rinsing is important to get rid of the residue as well as the cleaning agent.

With the right cleaning agent, this process is less tedious and more efficient. Let the detergent chemistry do the trick instead of hours of vigorous mopping or scrubbing!

Cleaning your harvesting and processing equipment are likely cutting into your production time!

Harvesting equipment like rotary trimmers, conveyor belts, or processing machines like extractors are installed to make the job faster. However, cleaning these machines are often tricky because of the design or the size of the equipment. It is nearly impossible to have a complete manual wipe-down of the equipment without having to pull them apart to clean and then re-assemble them, which again is not possible in the case of large extractors. For rotary trimmers, manual cleaning of each blade could be painstakingly long and dangerous. Traditional cleaning solutions that need multiple cleaning steps for a satisfactory cleaning increase equipment downtime, which means that they reduce production time.

So, what is the solution?

Semi-automated or automated cleaning process with Chematic® 420 having minimum cleaning cycles is possible as this detergent pulls off cannabis and related residues from the equipment surface and keeps it in suspension till it is flushed away, thus avoiding re-deposition and the need to re-clean. Depending on the processing stage, the detergent concentration and cleaning process can be optimized to achieve efficient cleaning and reproducible results without extensive manual intervention.

4 Reasons to choose Chematic 420 for Cannabis cleaning

The main reasons for choosing formulated detergents like Chematic to clean Cannabis residues are

-

To ensure operator, environmental, and equipment safety

-

Downtime reduction

-

Maximum equipment utilization (equipment longevity)

-

Savings – Resource and labor costs

Elaborating on these points, we can conclude that considering all cleaning variables above before moving cleaning to full-scale production, helps in identifying your optimal cleaning process that satisfies the profit requirements of a company. This ensures that your cleaning is consistent, robust, and repeatable and creates minimal resource usage and downtime while maximizing your equipment utilization.

A complete solution for Cannabis cleaning

You are not alone when facing your cleaning challenges. Dober’s Chematic Cleaning Chemistries and custom cleaning evaluations reduce your cleaning time and eliminate the need to re-clean equipment. We pride ourselves on thinking differently about cleaning. We believe that every production facility is unique and so are the residues they create. This is the reason we develop cleaning detergents that are formulated for you and not "off-the-shelf" solutions.

Chematic® 420 is a custom-formulated Cannabis cleaner that is designed to effectively clean all cannabis residues ranging from the viscous resinous soil at the harvesting stage to the oily residue observed at the production stage of Cannabis / CBD / Hemp containing formulations.