Industrial Cleaning Detergents for Nutraceutical Manufacturers

Nutraceuticals

The value of the nutraceutical market is expected to top $100 billion within the next few years, and that’s in the U.S. alone. Clearly, there is plenty of money to be made by adept nutraceutical companies. Defined as foods or foodstuffs that offer significant health benefits, nutraceuticals are considered to be a subset of the larger catch-all category of dietary supplements.

“Functional foods” are generally viewed as whole foods with especially significant health benefits. One example is wild salmon. It’s rich in the essential nutrients, omega-3 fatty acids, and supplies the potent natural antioxidant astaxanthin, not to mention complete, lean protein. Examples of nutraceuticals might include fish oil in pill form (a source of essential omega-3 fatty acids), or astaxanthin itself, also available as a softgel.

There are many types of nutraceuticals. In general, though, nutraceuticals tend to feature isolated nutrients believed to play a special role in promoting a particular aspect of health. However, unlike drugs, manufacturers cannot make specific statements regarding their products’ ability to “treat, diagnose, prevent or cure diseases.” Many types of nutraceuticals are touted as being “supportive” of healthy functions, although marketing materials frequently allude to their purported roles in potential prevention.

Dietary supplements and functional foods may be purchased virtually anywhere, from the grocery store or farmers market, to the drug store. Yet nutraceuticals are viewed somewhat differently. They are generally pharmaceutical-grade, standardized nutrients packaged and sold in standardized doses. Nevertheless, the U.S. FDA considers them dietary supplements or food additives. As such, they are not especially well-regulated. Indeed, the term “nutraceutical” is not even defined under U.S. law. However, while the FDA tends to be hands-off regarding nutraceuticals, it requires that they must be manufactured according to cGMP standards.

The Dangers of Unclean Manufacturing Equipment

The equipment used to process a given nutraceutical must meet stringent requirements for cleanliness. Demand for liquid nutraceuticals has been robust, and this underscores the importance of proper cleaning. Liquids, especially those rich in lipids, may be particularly challenging to clean, as these types of nutraceuticals tend to leave tricky residues.

Without a validated cleaning process in place, manufacturers run the risk of introducing cross contamination into their production lines during process changeovers, etc. The nutraceutical industry relies heavily on self-policing to maintain high-quality standards. When shoddy production results in problematic products reaching the market, the entire industry can suffer the consequences, for years to come.

Dober's Formulated Detergents

That’s where Dober’s formulated detergents come into play. Our Chematic® line of industrial critical cleaning detergents is carefully formulated to address your cleaning challenges. We work with clients, from inception to implementation, to develop cleaning agents specifically tailored to address a given cleaning challenge. By including us in your cleaning journey from the start of your process evaluation, we can work with you to devise the appropriate cleaning solution and achieve cleaning validation.

Nutraceutical Critical Cleaning Chemicals

We specialize in matching the right detergent formulations to specific cleaning challenges.We take a scientific approach, learning all we can about your cleaning goals and parameters, with an eye toward boosting your production capacity and reducing time — and money — spent on downtime.

Obviously, less time spent on cleaning means lower labor costs, and longer production run times. Of course, our nutraceutical critical cleaning solutions also ensure safe, efficient removal of residues, in minimal time.

How Dober's Solutions Build Business Efficiencies

Efficient businesses become so by anticipating potential future problems, minimizing downtime, ensuring quality, and providing for worker — and consumer — safety. By choosing Dober, you can rest assured we will work with you to achieve these goals and more. Satisfied customers have reported increased production capacity, maximized use of assets, and enhanced operator safety. With our product(s), you can expect to reduce time spent cleaning, while slashing contamination risk, avoiding the need to re-clean, and achieving validation quickly and efficiently.

Our Process

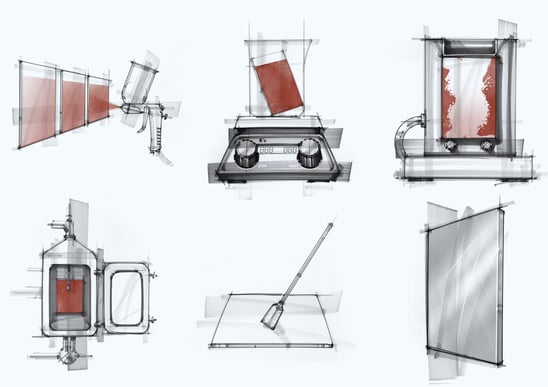

Experience has taught us some valuable lessons regarding the most efficient methods for partnering with our clients to achieve validation. We begin by obtaining data from you regarding your process. We study your data, and technicians in our Chematic® lab recreate your conditions. We propose an appropriate cleaning plan, and then we perform a Cleaning Study. Using data gleaned from that study, we optimize our approach. Finally, we deliver our findings to you and work toward obtaining validation after a series of studies and on-site trials.

.jpg?width=600&name=Chematic_Containers_01%20(1).jpg)