SRG2 Brings Liquid Control to Your Water Treatment Program

Since Smart Release Technology came to the market in 2007, it was viewed as a great option where it fit but didn’t suit every cooling water application or fill a customer need for control capability.

We can finally put that concern to rest — you can now control your Smart Release program just like an all-liquid program.

We recently touched on the evolution of the Smart Release product line leading up to our latest innovation in SRG2 (Smart Release Generation 2).

Now, it's time to dive a little deeper and look at what makes SRG2 the best of both worlds (i.e., of both liquid and solid water treatment programs).

What does it mean when we say SRG2 offers liquid control?

Smart Release Product Line Manager Justin Sullivan explains more in the video below:

SRG2 Has Liquid Control

Smart Release Generation 2 Technology (SRG2) allows you to control your solid program just as you could a liquid program. SRG2 brings the control ability of product feed to the table, using the same coated technology as before:

- Scale and corrosion products are controlled using a PTSA control set point

- Oxidizing biocides feed based on ORP or timer controlled

- Non-oxidizing biocides are on a timer-controlled scheme

If you have the proper controller in place at your customer location, remote monitoring capabilities of your system are practical. The system also comes with automated alarms and scheduled service reports.

Rest assured, your cooling water assets would be properly protected.

Liquid Control, Without the Hassle

All-liquid cooling water programs have been prominent in our industry for years, given it has been the norm for professional water treaters and customers alike. After all, as with all things in life, sometimes you just become comfortable with what you already know and, as a result, might not consider other, more effective options.

Any cooling water treatment liquid program has its associated challenges, such as chemical spills or leaks, mechanical issues with chemical metering pumps, hazardous products, and many more.

With a Smart Release Technology program, you can get the benefits of liquid control without the challenges associated with an all-liquid program.

Implementing a Smart Release Technology program at your customer location, you’ll get to enjoy the benefits of what a Smart Release Technology program will provide and much more.

Proven Results

With Smart Release Technology now having control, you can control your cooling tower water application like a liquid program but deliver it with a solid product. In the past, you would load your tablets into your feeder, set your flow rate to 1-3 gpm, and come back in 30 days to replace the tablets.

With SRG2, we are getting the life out of the tablets, extending them in some cases up to 60-75 days in the feeder, depending upon your application.

Utilizing the PTSA constituent in the Smart Release tablets, you can do just that! Depending upon which product you use — CW211-SR, CW311-SR, or CW350-SR — each of them contains PTSA as an active ingredient. All you need to know is what PTSA range you configure your in-line PTSA sensor to control to.

Let’s use CW311-SR, for example. The target dosage is 25 ppm as product, with optimal dosage range being 20-30 ppm. What does that constitute in terms of PTSA?

Well, ideally you want to be around 40 ppb as PTSA, but being 10-15% outside the optimal dosage range is OK.

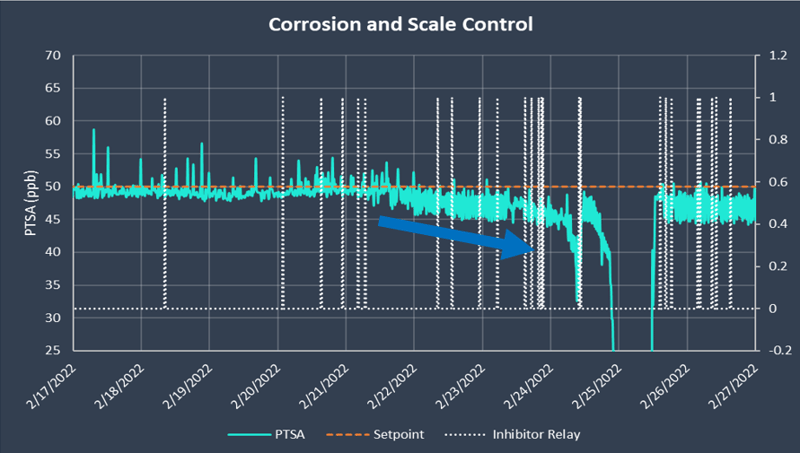

The graph below highlights a few key critical components of running a successful program using Smart Release Technology.

- As highlighted, great corrosion and scale control is seen early in the graph, from 2/17/22 through 2/22/22.

- PTSA levels start to slowly trend downward as seen, indicating probable tablet exhaustion is taking place, and the relay is opening and closing more frequently to keep up with your PTSA set point.

- On 2/25/22, tablets become exhausted to the point where they were replaced, and the feeder reloaded with fresh product.

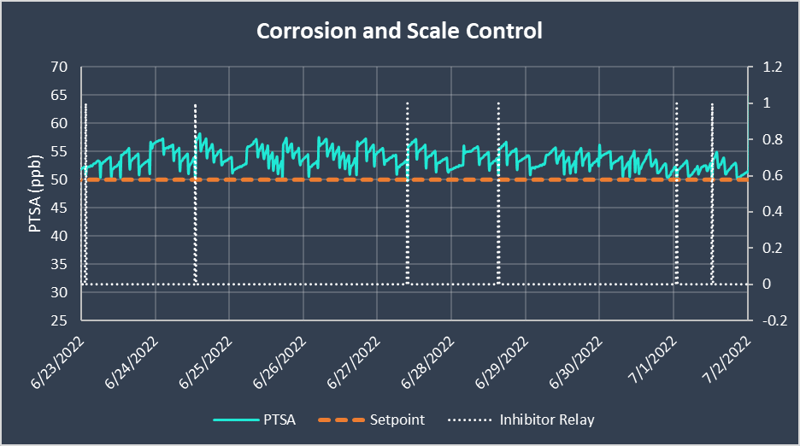

The graph below shows outstanding PTSA control across the 50 ppb setpoint over the course of a week. This system is operating on two 650-ton chillers.

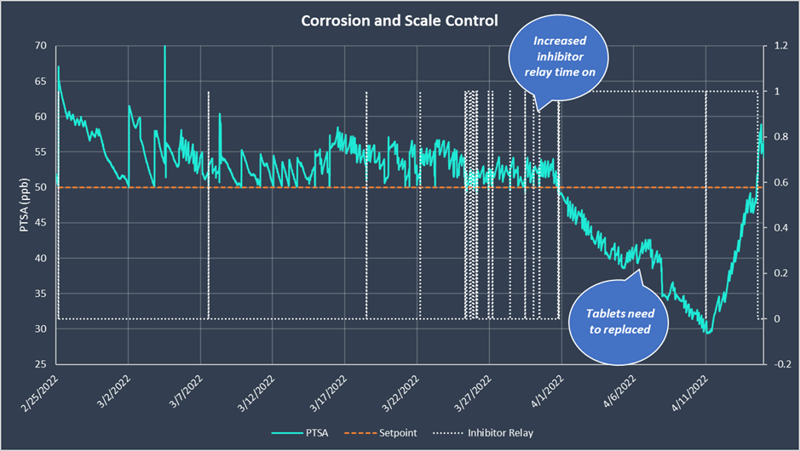

As seen in previous trend graphs, proper corrosion and scale control is seen over this extended period. Takeaways from this trend include the following:

- Increased inhibitor relay time on indicating tablet exhaustion is nearing, and a service visit is required to replace or reload your corrosion and scale tablets.

- Tablets needing to be replaced as the PTSA levels in the system are decreasing day over day.

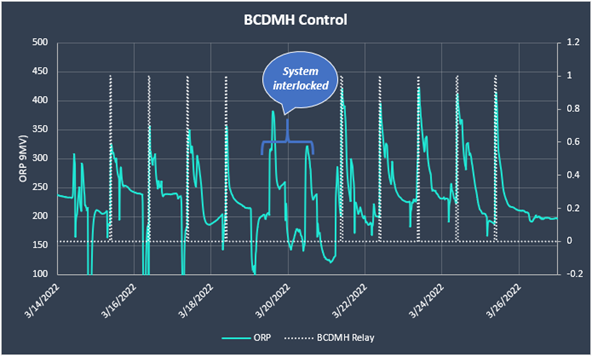

With SRG2, you can use timer control functions for your feed of BCDMH and Bio-Clear (DBNPA) products.

The graph below depicts a timer control BCDMH feed scheme. As seen, you see excellent ORP spike correlations with your BCDMH relay timer. Another option for BCDMH feed is utilizing the ORP setpoint functionality built into your control, should you desire that.

Energy-Efficient System

First and foremost, you’ll enjoy an energy-efficient system with SRG2.

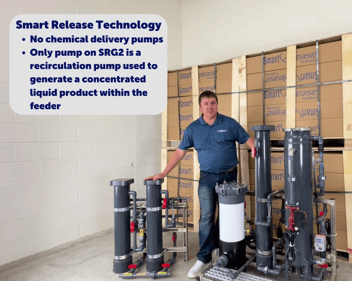

Smart Release skids and feeders do not have any chemical metering pumps to deliver product to your cooling water system. Have peace of mind your chemicals are being fed as intended, without the worry of common challenges with chemical metering pumps.

The only pump you will find on a Smart Release Technology system is on the SRG2, which is a three-speed, recirculating pump featuring a cast iron housing and removable check valve.

Safety and Exposure

Personnel safety and exposure are always paramount when operating a water treatment program.

Do you want to eliminate hauling around 5-gallon pails of chemical up and down flights of stairs? Would you prefer not having to maneuver chemical drums in tight mechanical rooms?

With ergonomically friendly packaging (no box or pail weighs more than 25 pounds), you can now get up that flight of stairs or to the back corner of the mechanical room with minimal effort.

In the brief video below, you can see a demonstration of how much easier it is to transport our solid tablets versus chemicals for a liquid program.

Reducing exposure of hazardous chemicals, not only for you but your customer, should be at the forefront of your mind.

Storage, Handling Benefits of SRG2 Technology

Smart Release Technology also does not require you to have containment. Our solid-based technologies require a small footprint when compared with traditional liquid programs. As such, storing product on-site is much, much easier.

When it comes to shipping and handling product and material for a Smart Release program, you’ll enjoy shorter lead times and quicker delivery. We can ship our products via air, making the ability to get product in your hands quicker than competing all-liquid programs.

Interested in a summary of our SRG2 technology? Download our SRG2 brochure below.