Oil-Water Separation in Centralized Waste Treatment

Oil and water separation in centralized waste treatment facilities is a foundational task that has to happen effectively for consistent results across a wide variety of waste types.

Centralized waste treatment (CWT) facilities operate at the intersection of complexity and compliance. Unlike single-industry wastewater plants, centralized waste treatment sites accept diverse industrial waste streams from multiple generators. These streams often exhibit varying chemistry, contaminant loads, and physical characteristics.

That means CTW facilities wear multiple hats, if you will, and operators have to be skilled problem-solvers.

Among the most persistent and technically challenging contaminants in these facilities is oil.

Effective oil and water separation in centralized waste treatment is not simply a mechanical and/or chemical process. Effective separation is a risk management function that protects downstream treatment processes, ensures regulatory compliance, and stabilizes operations.

Understanding how oil behaves in mixed industrial waste streams, and how to design systems that handle variability, is central to running a reliable CWT operation. No pun intended, but you need to go with the flow if you're going to run an effective CWT operation.

oil-water Separation in Centralized Waste treatment

So what does separation for centralized waste treatment facilities really mean?

Unlike other industries, centralized waste treatment facilities receive wastewater and liquid waste from off-site industrial generators. Those waste streams can come from many forms, as the graphic below shows.

In fact, that's the defining characteristic of centralized waste treatment: variability. Unlike a dedicated refinery or food plant with relatively consistent wastewater, CWT sites must handle fluctuating oil concentrations, surfactant loads, solvents, solids, and pH conditions, with conditions sometimes changing within the same day.

As a result, robust oil–water separation essential addressing many different waste streams.

-

What does cwt often include?

• Refinery slops and tank bottoms

• Petrochemical wastewater

• Metal finishing rinse waters

• Transportation terminal washouts

• Oily stormwater

• Hazardous and non-hazardous industrial process water

-

Centralized waste treatment forms

-

Oil in centralized waste treatment facilities can exist in several forms:

- Free oil (readily separable by gravity)

- Dispersed oil (small droplets suspended in water)

- Emulsified oil (chemically stabilized droplets)

- Dissolved organics (non-separable by physical means)

Discharge permits often regulate oil and grease (O&G) concentrations in the range of 10–100 mg/L, depending on the receiving body or publicly owned treatment works (POTW). Oil carryover can:

- Inhibit biological treatment systems

- Cause foaming and floating sludge mats

- Overload dissolved air flotation (DAF) systems

- Increase sludge disposal costs

- Trigger permit violations

Because oil also associates with COD and total petroleum hydrocarbons (TPH), poor separation can create downstream performance instability across the entire treatment train.

For these reasons, oil and water separation in centralized waste treatment is typically staged and multibarrier by design.

-

Top Challenges for Centralized waste treatment Sites

Below are some of the top challenges for CWT professionals:

1. Extreme Variability

Incoming loads at centralized waste treatment sites may vary dramatically in oil content, droplet size distribution, solvent presence, and surfactant levels. A single tanker load can destabilize a previously stable separation system. That means effective equalization and well-organized staged treatment are critical.

In a nutshell, you need to bring stability to what can feel like a chaotic mix of influents.

2. Chemically Stabilized Emulsions

Detergents and solvents common in industrial wastes can prevent oil droplets from coalescing. These emulsions resist gravity separation and often require chemical destabilization or electrocoagulation to break.

3. Mixed Regulatory Oversight

Centralized waste treatment facilities often operate under overlapping regulatory frameworks. Oil removal is not just an operational thing to be perfect, it is a compliance requirement under federal effluent limitation guidelines and site-specific permits. Bottom line, it can be challenging at times to balance these varying guidelines and ensure your treatment process is doing what it should.

4. Sludge Management

Oil-rich sludges generated during separation may:

- Have high calorific value

- Require hazardous waste classification

- Increase disposal costs

Sludge handling capacity must scale with separation performance improvements.

-

Centralized Waste Treatment tips

-

Characterize Incoming Waste

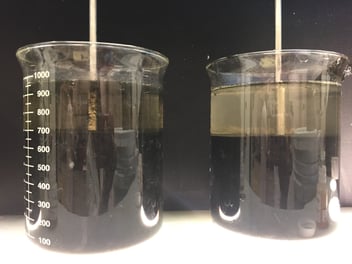

You've got to know what you're getting in so you can treat it effectively. Facilities should require detailed manifests and perform jar testing for new waste types. A few parameters to think about include oil and grease, TPH, COD, surfactants, pH, and droplet size distribution. By characterizing your incoming waste, you cut down on surprises and can make better decisions when it comes to treatment chemicals.

Just like you might do a quick online map search of an area of town around which you plan to go out for an evening — to collect information about available parking, things to do in the area, etc. — this is much the same.

Preparation is the first ingredient in a successful treatment plan.

Use Staged Separation

A multibarrier approach improves reliability, which typically means the following:

- Bulk gravity separation

- Chemical destabilization

- Flotation

- Polishing (if required)

Each stage reduces load on downstream systems, minimizing upset risk in centralized waste treatment operations. In other words, you'll need to take it one step at a time.

Optimize Chemical Destabilization

Emulsified oil requires charge neutralization before flotation. Routine jar testing ensures effective coagulant and polymer dosing. Overfeeding polymers can increase sludge production or restabilize emulsions, so dose control is critical.

-

Control Hydraulics

Laminar flow in gravity units, sufficient retention time, and proper sludge removal frequency all affect performance. Short-circuiting can significantly reduce oil removal efficiency regardless of equipment size.

-

Monitor in Real Time

Online turbidity, oil analyzers, flow monitoring, and pH control systems allow operators to respond quickly to variability. Alarm thresholds help prevent oil carryover into biological treatment systems. This is true for many industries, but real-time data is a game-changer.

Developments in centralized waste treatment: Advanced oxidation

- As we always note in other areas of the water treatment world, it's critical to continue your ongoing education as a water treater ... that means, in part, keeping up to date on the latest in research and development.

- Of note in the CWT space is the ongoing development of advanced oxidation processes used to break down pollutants in the variable waste streams one might find at a CWT facility.

- A 2025 paper in Catalysts reviewed recent developments in advanced oxidation methods for industrial water treatment.1

Citing growing complexity in industrial water treatment and the inadequacy of traditional methods to handle certain scenarios, Tian-Hua et al. write: -

In response to these challenges, advanced oxidation processes (AOPs) have emerged as a highly promising alternative for wastewater treatment [10]. AOPs are based on the generation of highly reactive oxidizing species, primarily hydroxyl radicals (·OH), which possess strong oxidizing capabilities and can effectively degrade a wide range of pollutants through non-selective oxidation pathways [11]. The mechanisms of AOPs involve the formation of hydroxyl radicals through various pathways [12], such as the photolysis of hydrogen peroxide, UV irradiation, and the catalytic decomposition of oxidants in the presence of transition metals or semiconductors. These reactive species can initiate radical chain reactions, leading to the breakdown of complex organic molecules and ultimately their complete mineralization into carbon dioxide, water, and inorganic ions.

Furthermore, in relation to CWT, the researchers cite advanced oxidation processes' ability to deal with variability:

-

The advantages of AOPs lie in their broad applicability to various types of wastewater, high oxidation efficiency, rapid reaction kinetics, and the potential for complete degradation of recalcitrant pollutants [13]. These characteristics make AOPs particularly suitable for treating wastewater containing emerging contaminants and other pollutants that are difficult to remove by conventional methods.

Elsewhere, 2024 review published in Chemical Engineering Science compared oxidation-based hybrid technologies in industrial water treatment, specifically coagulation-flocculation, electrochemical oxidation (ECO), and ozone oxidation, targeting the removal of landfill leachates.2

The authors concluded that the hybridized treatment methods performed better than ECO alone.

"Wastewater treatment by PAC-AP/ECO and CO-SC/ECO resulted in relatively high COD removal rates of 93 % and 90 %, respectively in comparison with 69 % by ECO alone," the authors write. "At an optimal pH, the TN amount decreased from 2300 to 1580 mg L−1 through coagulation-flocculation/ECO, which was 10 times greater than that obtained by the ECO alone."The researchers also studied differences in material composition, including the effect on color removal when using an aluminum anode versus a graphite anode for electrochemical oxidation, concluding that aluminum was more effective.

Table 1 of the paper by Mehrkhah et al. provides a full summary of the researchers' findings on the removal rates of various hybrid options tested, including the wastewater source (ranging from textile to livestock to landfill leachate).

in summary

Oil and water separation in centralized waste treatment facilities is fundamentally about managing variability. No single technology provides a universal solution. Instead, successful centralized waste treatment operations rely on staged systems, chemical optimization, hydraulic control, and real-time monitoring.

In centralized waste treatment, successful oil-water separation is a safeguard for biological stability, sludge management, and regulatory compliance. CWT facilities play a key role in our society, from an industrial and public health sense ... and separating oil and water is a cornerstone of that key role.

One final note: a Dober case study outlined the results from the use of Dober product for wastewater treatment of oily waste from various manufacturing types. The result? A 66% reduction in sludge volume.

Interested in speaking to a Dober expert to chat about how GreenFloc products can help you with your wastewater treatment separation needs?

-

References

- 1. Zheng, T.-H., Zhang, Z.-Z., Liu, Y., & Zou, L.-H. (2025). Recent Progress in Catalytically Driven Advanced Oxidation Processes for Wastewater Treatment. Catalysts, 15(8), 761. https://doi.org/10.3390/catal15080761

- 2. Roya Mehrkhah, So Yeon Park, Jun Hee Lee, Sun Young Kim, Byoung Ho Lee, A comparative study of advanced oxidation-based hybrid technologies for industrial wastewater treatment: An engineering perspective, Chemical Engineering Science, Volume 286, 2024, 119675, ISSN 0009-2509, https://doi.org/10.1016/j.ces.2023.119675. (https://www.sciencedirect.com/science/article/pii/S0009250923012319).