Each manufacturing plant has its own unique wastewater. However, despite the industry, oily wastewater can be broken down into 4 categories. Thus, no matter how unique the water is, it is going to fall into at least one of these categories. Understanding which category of oily wastewater your plant produces will help lead to using the correct treatment equipment and chemicals.

Emulsions

For this kind of oily wastewater, droplets of oil are dispersed throughout water. Water is the dispersion medium and is in the continuous phase, while oil is in the dispersion phase.

The oil must be removed from the water for the water to meet discharge requirements. This is typically done using demulsifiers, which allow for the coalescence and removal of the oil droplets. In the case of emulsions, the oil contained in the water is typically waste oil; therefore, product quality and preserving the water is more important than the product quality of the oil.

Inverse Emulsions

Inverse emulsions are the opposite of emulsions. This type of oily wastewater refers to droplets of water dispersed within oil droplets. In this case, the water is a byproduct of producing the oil and thus must be removed from the oil.

It is especially important to completely dehydrate the oil droplets in order for refineries to meet crude oil requirements. This is typically accomplished with reverse emulsion breakers, which assist in the separation of water from oil.

Total Dissolved Solids

This kind of oily wastewater has small particles dispersed throughout. The main characteristic is the particles are not able to be filtered out with filter paper.

Eventually, the particles will settle to the bottom under the natural influence of gravity. However, this is a time-consuming method of treatment and isn't ideal for a plant trying to maintain productivity standards.

Suspended Solids

Similar to colloidal suspension, suspended solids consist of particles in the water.

Typically, suspended solids are floating in the water, rather than dispersed. These particles are usually larger and therefore quicker to settle out than colloidal suspension.

Since the particles are larger, they can be filtered out much easier. However, treatment often still requires coagulants and flocculants to speed up the process.

Download List of Water Treatment Companies: If you’re ready to start evaluating companies, here is a list to get you started. Included in this guide are some of the top water treatment companies in the United States.

Download List of Water Treatment Companies: If you’re ready to start evaluating companies, here is a list to get you started. Included in this guide are some of the top water treatment companies in the United States.

Dissolved Air Flotation

Poor dissolved air flotation (DAF) performance usually results in solids carryover, which can cause increased surcharge cost and, possibly, discharge violations. The single biggest reason for DAF failure is poor dissolved or “white water” quality, which is the mechanism for water/solids separation. Improper air pressures and recycle flows are typically the main culprits.

Improper chemical selection and/or dosage can also impact DAF performance through the production of microfloc instead of macrofloc.

The larger the floc particle, the more surface area for the air to attach itself to and, therefore, more effective solids separation is achieved.

Sludge Buildup

Sludge is a by-product of treating suspended solids and colloidal suspension. It is a collection of the solids, typically on the bottom of the treatment system.

If there is too much sludge in any of the treatment equipment, the equipment will have to be turned off and sludge needs to be manually removed, which equates to wasted time and money.

Sludge buildup in a DAF system that is too thick of a blanket can result in solids carryover, and decrease the effectiveness of the DAF.

Read how one company saved $46,000 a year by lowering their sludge disposal cost

Product Quality

This is especially important for the food and beverage industry and oil and gas industry. If the wrong chemicals are being used to treat wastewater, specifically water that is intended to be reused throughout production, this can affect the overall quality of the produced items.

In the food and beverage industry, if still -contaminated water is used to produce food, then that food will not meet quality standards and will result in money lost.

-contaminated water is used to produce food, then that food will not meet quality standards and will result in money lost.

Similarly, if crude oil is not completely dehydrated, then it cannot be put through the refineries, resulting in delays and potential waste of precious fossil fuels.

Water Reuse

Since water is a charged resource for facilities, it is imperative to be able to reuse the water that is already in the plant.

One example of this is in industrial paint spray booth systems. The water must be treated before it can be recycled. If it is not treated properly, then this can affect product quality and the equipment (as contaminated water is then running through the systems).

Oil Sheen

An oil sheen on discharged water can mean shutting down production until the sheen is removed. Thus, is it especially important for manufacturers, specifically in the primary metals and oil and gas industries, to act to prevent sheen formation.

Any of the above treatment issues are typically a direct result of using the wrong chemistry to treat your wastewater.

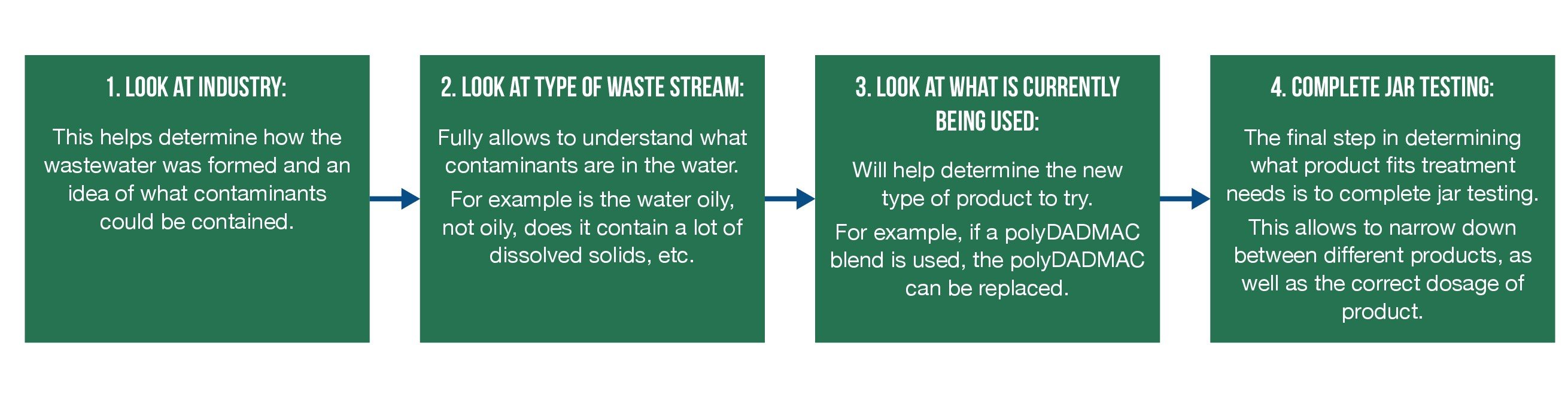

Alongside this, although every wastewater falls into at least one category, each waste stream is unique. Furthermore, every waste stream requires a hands-on process to determine the correct product and, most importantly, dosage of said product. The infographic below shows the flow of data collection and testing necessary in order to choose the right treatment plan.

It is vital to find a chemical company that understands all of the factors necessary to maximize the performance of your wastewater treatment. By working with a company willing to develop unique solutions to treat your unique emulsions, you are able to lower treatment dosages and lower your overall use cost.

Dober's GreenFloc Natural Coagulants are specifically formulated to treat oily wastewater.

We go further by providing you with more than just a typical sample kit. We provide you with the services you need and the best chemistries for water and oil emulsions on the market today.