INTERN VIEW: Oil Refinery Case Study

There is a strong connection between how we produce our energy and how we manage our water resources; this week I wanted to take a closer look into some real-world applications of that concept. I was interested to learn how an energy company may have to deal with water treatment issues, such as a refinery having to treat its wastewater for oil. By looking through the water treatment case studies, it’s clear to see that Dober’s Natural Coagulants have a lot of experience doing just that.

One case study I looked at was a large US oil refinery that wanted to increase environmental performance while cutting costs on coagulant usage in their wastewater processing units. The refinery was challenged with: the loss of a process water tank, a drive to improve environmental results at the wastewater treatment plant, and better cost control for the coagulant used throughout the refinery.

Dober's GreenFloc product line consists of sustainable, effective, and innovative natural coagulants that can be used in a wide variety of applications—they are particularly good at separating oil from water. For this application, Dober’s researchers in the Innovation and Technology Lab developed a replacement for the incumbent synthetic chemical (a polyDADMAC/PAC blend). This new product, GFT 6173, was then tested and validated on-site with the customer. This product was finally tested full-scale at the refinery.

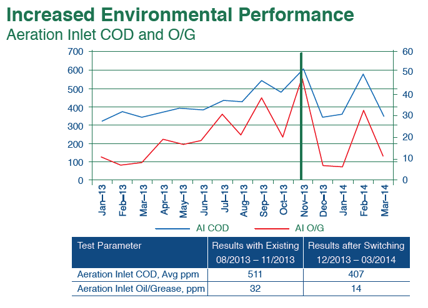

During testing, this new product was able to exceed all of the refinery’s standards of excellence. Specifically: it reduced the Aeration Inlet COD by 20% and Oil/Grease by 44%. The refinery’s quarterly chemical spending was reduced by 18%. The success of these results meant that the new coagulant was put in use full-time at the refinery, and it has continued the same sustainable performance since.

In order to produce cost-effective energy, companies need to make sure all of their processes are as efficient as possible, including the management of their wastewater. By using natural chemistries designed for separating oil and water, this refinery is now more environmentally friendly while reducing costs and achieving its production goals. Many people view environmental responsibility as an additional cost, but as it turns out it can produce a more effective solution and ultimately lower costs.