- In the cosmetic industry, "Consumers are increasingly attracted towards cosmetics with natural ingredients as these products are positioned as healthier and safer alternatives to conventional cosmetics."

- Chitosan is "extensively used to manufacture bandages owing to its exceptional wound healing characteristics."

(Untreated water on the left, treated water using a chitosan solution on the right)

Environmentally Friendly

Chitosan based solutions have been trusted across North America in reducing turbidity and removing unwanted contaminants in the most sensitive ecosystems such as hydroelectric dam restoration and storm water canals. Since chitosan is acrylamide-free and 100% biodegradable through enzymatic activity, it ensures there are no bio-accumulation concerns after treatment.

Superior Performance

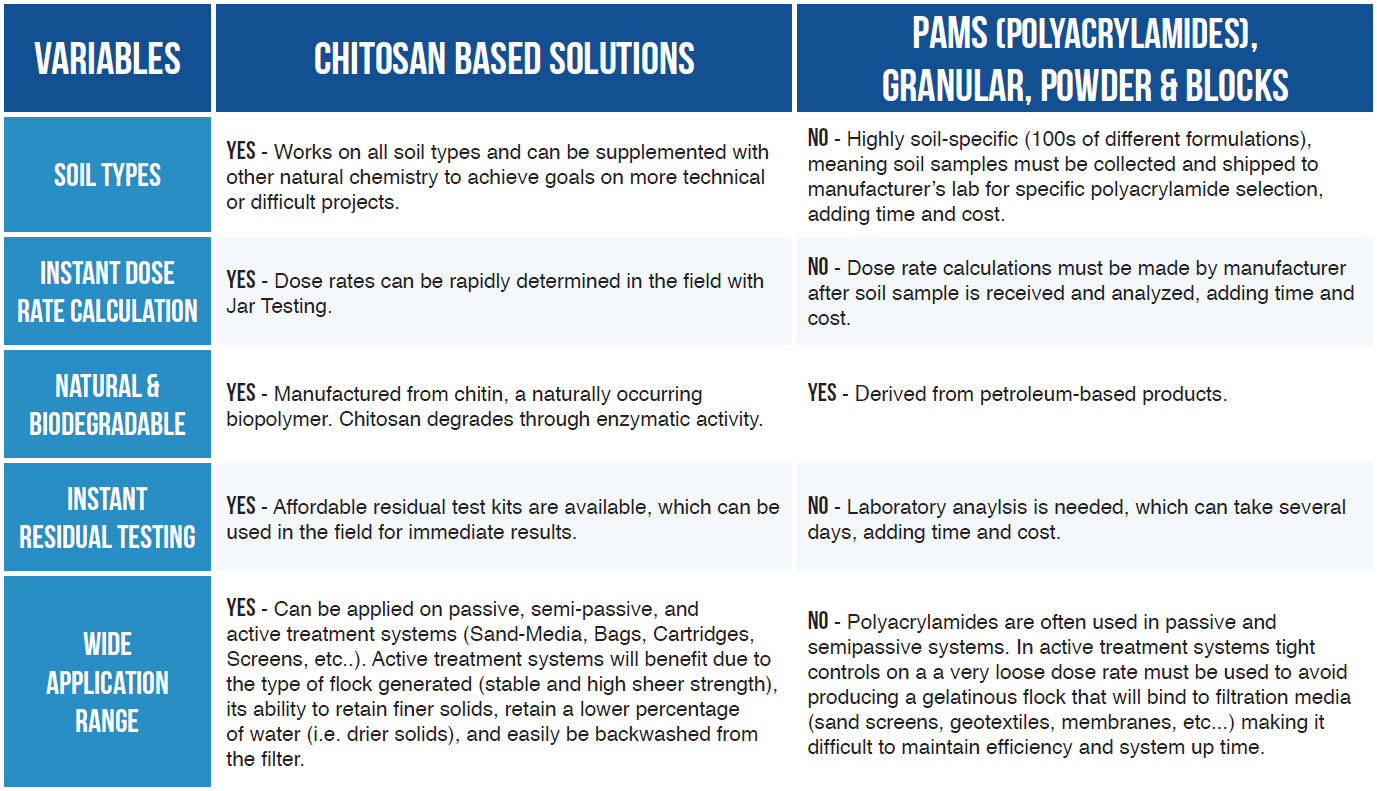

Solutions involving chitosan flocculants have more benefits than simply being environmentally friendly. Chitosan performs better than alternatives too. Chitosan-based treatment systems are adaptable and versatile to achieve water quality goals on projects with varying site conditions, soil types, and seasons. Additionally, it generates solids with a lower percentage of water entrained, which creates a stable and strong floc. A high-quality floc allows treatment systems to run more efficiently with benefits both upstream and downstream:

- Fast settling times

- Easy filtration and backwashing

- Reduce hauling and disposal costs

- Removes a variety of solids - including fine sediment, heavy metals, and PCBs

- Improve water clarity

Simply put, chitosan provides a more effective treatment at lower dosages than traditional synthetic polymers in most applications.

Residual Test Kit

The EPA’s Clean Water Act prohibits the discharge of toxic pollutants in amounts that can adversely impact freshwater and marine organisms. Water quality permits often require you to test effluent water for specific analytes to verify you are compliant with local and federal discharge regulations.

Depending on the specific regulations and requirements of your project, it may also be required to verify that treatment chemicals are not discharged in the effluent water. Using chitosan-based flocculants as part of your water treatment solution allows you to complete residual testing on-site in about 10 minutes. These residual tests empower you to verify and document that no residual chemistry is being released back into the environment – ensuring you are meeting government regulation, while maintaining production time, and eliminating the costs and hassle of using an outside lab that would be required by synthetic treatment chemicals, like polyacrylamides.

When using synthetic polymer flocculants - like PAMs - Whole Effluent Toxicity (WET) tests are used to measure the wastewater’s effects on organisms’ ability to survive. These toxicity tests are generally done by a third party, take between 24-96 hours to complete, and have been known to cost upwards of a few thousand dollars.

Regulations in the water industry can be complex and often times leave you more confused about what you can and cannot use to achieve water quality goals. Across applications and industries, there are a wide variety of guidelines and requirements at the federal, state, and local level. For example, there may be limits on a specific contaminant like Total Suspended Solids (TSS) or on a characteristic of water, like turbidity.

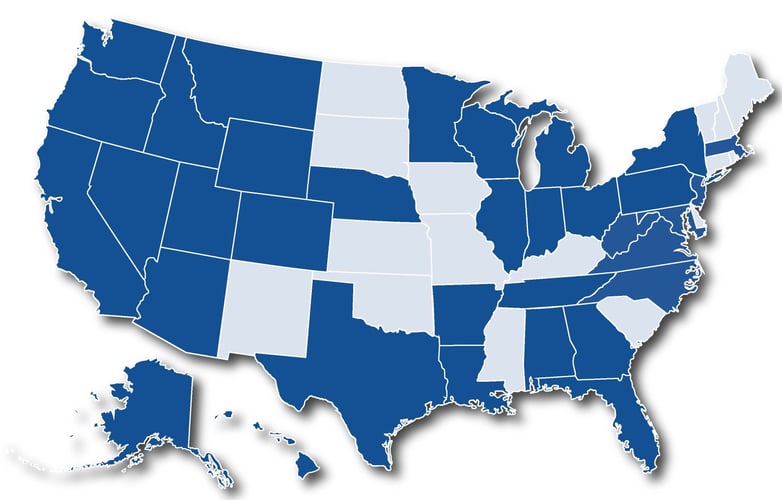

One question we often receive is, "Is chitosan approved for use in my state?". The answer to this question is usually, "Yes". In some cases, a regulatory agency approves treatment chemicals on a case-by-case basis. We are happy to provide submittal documents and assist in the regulatory approval process, as we personally have shipped chitosan flocculating agents to treat water in over 35 states and 3 Canadian provinces.

(States in blue have used our Chitosan Products)

Some of the most stringent and environmentally sensitive regulatory agencies prefer chitosan-based flocculants over synthetic alternatives for water treatment, based on toxicity testing that demonstrates no harm to aquatic organisms at recommended dosages.

A few states, including California, have taken the next step to ensure safety and traceability of treatment chemistries by requiring residual field tests to prove no residual treatment chemistries are leaving the site in discharged water. While a residual test kit exists for a chitosan based solution, no economically comparable residual polyacrylamide test kit is available for use in the field.

Chitosan flocculants are used in systems ranging from active water treatment systems for mobile water treatment and water clarification, to semi-passive pumped water incorporating coarse filtration and geotextile bags, and completely passive water treatment models, such as bio-filtration and check dams.

While polyacrylamides can be used with passive and semi-passive systems, it is difficult to use them with active treatment systems since they require tight controls on a very loose dose rate. Otherwise, they produce a gelatinous flock that will bind to filtration media and make it difficult to maintain efficiency and system up time.

Active Water Treatment System

TYPICAL RESULTS: 10-35 NTU

This acrylamide-free treatment system delivers consistent results. It has an identical footprint compared to traditional active treatment systems. There is reduced frequency of backwashing compared to traditional active treatment systems. The actual flow range is dependent on mechanized equipment and pumping capabilities. It can reduce operational costs compared to traditional active treatment systems. The use of HaloKlear natural flocculants enhances the efficiency of most filtration equipment used in active treatment systems, by aiding the capture of finer solids, reducing the frequency of backwash, allowing faster settling of particles in settling tanks, and providing solids/contaminants that have a lower percentage of water, which reduces hauling and disposal costs.

Using a chitosan based solution enhances the efficiency and consistency of most filtration equipment used in active treatment systems, by aiding the capture of finer solids, reduce the frequency and difficulty of back-washing, allow the particles to settle faster in settling tanks, and producing solids and contaminants that have a lower percentage of water, which reduces hauling and disposal costs.

Semi-Passive Water Treatment System

TYPICAL RESULTS: 20-50 NTU

Semi-passive systems deliver consistent results. It's an acrylamide-free treatment system with low maintenance requirement and low mechanized equipment requirement. This significantly reduces the footprint compared to traditional active treatment systems. It requires the HaloKlear SockMaster Manifold kit and pump (rated 100-500 GPM), and does not require backwashing. This is low cost compared to traditional active treatment systems. It may use coarse filtration, settling, or both to improve cost effectiveness. Semi-passive systems can be used in conjunction with passive treatment models. They may involve contaminant and nutrient removal. Plug-in-play a variety of configurations including: BMPs, dewaterting bags, and recirculation systems.

Since only low mechanized equipment is required, the maintenance and cost is significantly cheaper than using an active system. When using a chitosan solution with a semi-passive system, you can expect to see the turbidity levels reduced to 20-50 NTUs, giving you a cost-effective model for meeting EPA & ELG requirements.

Passive Water Treatment System

TYPICAL RESULTS: 50-250 NTU

This acrylamide-free treatment system has the lowest maintenance requirement. There is no mechanized equipment required, which can reduce footprint by up to 50%. This system minimizes or eliminates the need for water storage on-site. Actual flow rates are dependent on best management practice (BMP) design and the frequency and severity of storm events. The passive system uses natural filtration and settling to reduce costs. It is a cost-effective model for meeting EPA & ELG requirements and is easily applied to new and existing BMPs. This is the lowest cost treatment system. Passive treatment systems are the most cost-effective model for meeting EPA requirements. Since there are no mechanized equipment requirements and no need for water storage, it typically requires the least amount of maintenance and can be easily applied to new and existing BMPs. The combination of a chitosan solution and natural filtration, you can expect to reduce your turbidity down to anywhere between 50-250 NTUs.

Learn more about these treatment schemes:

Chitosan flocculants have been used for decades across a variety of industries because it performs so well in a wide variety of water treatment applications.

Construction

When soil is exposed during construction activities, water runoff generated by storm events tends to pick up soil particles and carry them to the nearest body of water. Particles also contaminate water when stormwater or groundwater enters into an excavation. During a construction project, site stormwater, runoff, or dewatering operations may need treatment in order to remove the particles that are in the water.

Larger particles, such as pebbles and sand, quickly settle to the bottom once the flow rate slows. However, clays and fine silts tend to stay suspended. These suspended particles result in turbidity that can travel many miles in streams or keep ponds and lakes looking muddy for a long time after a storm. Chitosan based flocculants can help remove turbidity caused by a wide variety of particle types and sizes.

Biosolids Management

Many wastewater lagoons suffer from sludge accumulation that becomes a maintenance project on an on-going basis or every few years. Lagoon sludge removal and dewatering is a common challenge for wastewater lagoon operators worldwide. Excess lagoon sludge can lead to higher effluent levels of BOD, TSS, and ammonia along with some unappealing and unneighborly lagoon odors. Chitosan based flocculants can help consolidate biosolids to make dredging and dewatering operations more efficient.

Industrial Storm Water

Polluted industrial storm water is a major source of environmental contamination. Runoff from industrial sites enters storm drains and is carried into local ponds, creeks, and rivers. Industrial contributors such as construction sites, often are a major source of oily waste, suspended solids, heavy metals and hydrocarbons pollution.

Tunneling & Drilling

Tunneling, boring, and drilling produce tremendous amounts of discharge water that is loaded with solids. Clay or bentonite slurries are often used to lubricate the drill or cutter heads as they run, increasing the volume of water and suspended solids discharged from the project. As the drill or cutter head advance vertically or horizontally, soil types will vary demanding a versatile treatment chemistry to remove the solids from the discharge water. Chitosan based flocculants can remove the solids from return water as soil types and site conditions change throughout the duration of a project.

Learn more about Chitosan for Water Treatment

Clean water naturally. At HaloKlear, a Dober company, our solutions include natural flocculants and natural coagulants designed to be environmentally responsible, cost effective and safe to handle while outperforming traditional chemical solutions.

With over 35 years of water treatment chemistry experience, Dober offers a dedicated team of analytical chemists, water treatment experts, and a complete sales and service team to solve your toughest water treatment chemistry challenges. Click the image below to learn more and we'd be happy to help you with any water treatment needs.