Cooling tower sustainability plays a critical role in cooling tower water treatment due to its significant impact on environmental conservation, energy efficiency and overall cost-effectiveness.

In this article, we'll briefly review some of the important aspects of cooling tower sustainability before diving into some nitty gritty calculations. Sustainability can take many forms; however, in the cooling tower industry, CO2 emissions associated with freight present the biggest opportunity for sustainability growth.

In simple terms, we sought to answer the question: How does Smart Release Technology stack up versus a liquid program in terms of carbon footprint associated with freight?

.png?width=1080&height=1080&name=Sustainability%20with%20Smart%20Release%20Technology%20(2).png)

In that vein, as companies continue to move toward "greener" solutions, what are they looking for?

By improving their cooling tower sustainability measures, they might be seeking to:

- Effect environmental change and be a part of the wider "green" movement

- Fulfill companywide mission to be more sustainable

- Save water

- Save energy/save on energy costs

Cooling towers are essential components of industrial and commercial facilities, as they help regulate the temperature of equipment and processes. However, their operation often consumes large amounts of water and energy, in addition to costs associated with transport of chemical treatment products.

Implementing sustainable practices in cooling tower water treatment can address these challenges in several ways.

-

Water Conservation: Sustainable cooling tower water treatment focuses on minimizing water consumption through the use of efficient water management strategies such as water recycling, reuse, and minimization of water losses. By implementing advanced technologies like water filtration and chemical treatments, facilities can significantly reduce their overall water usage, contributing to conservation efforts and reducing the strain on local water resources.

-

Energy Efficiency: Sustainable cooling tower water treatment emphasizes the use of energy-efficient technologies and practices to optimize cooling tower performance. By employing measures such as the use of energy-efficient pumps, optimized cooling tower design, and the integration of renewable energy sources, facilities can reduce their energy consumption and lower their carbon footprint. Enhanced energy efficiency not only contributes to environmental sustainability but also leads to substantial cost savings for the facility.

-

Environmental Impact: By adhering to strict environmental standards and regulations, facilities can mitigate the negative effects of cooling tower operations on surrounding ecosystems, thereby promoting environmental sustainability and fostering a healthier ecosystem for all.

-

Cost-Effectiveness: Implementing sustainable cooling tower water treatment practices can result in long-term cost savings for facilities. By reducing water and energy consumption, minimizing the use of chemicals, and optimizing overall system performance, facilities can cut down on operational costs and improve their financial bottom line.

By integrating sustainable practices into cooling tower water treatment processes, facilities can contribute to a more environmentally responsible and economically viable operation while ensuring the long-term viability of their cooling systems.

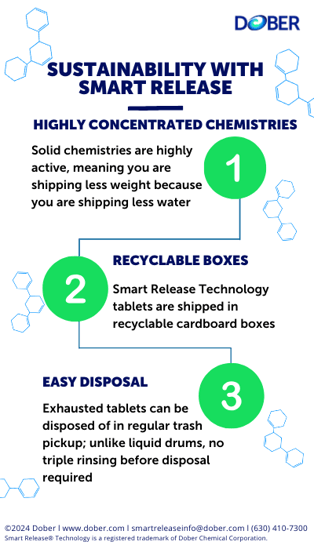

In the big picture, which aspects of the Smart Release Technology treatment program promote greater sustainability?

Here are three ways Smart Release Technology strives for sustainability:

- Solid chemistries are highly active, meaning you are shipping less weight because you are shipping less water

- Smart Release Technology tablets are shipped in recyclable cardboard boxes

- Exhausted tablets can be disposed of in regular trash pickup; unlike liquid drums, no triple rinsing before disposal required

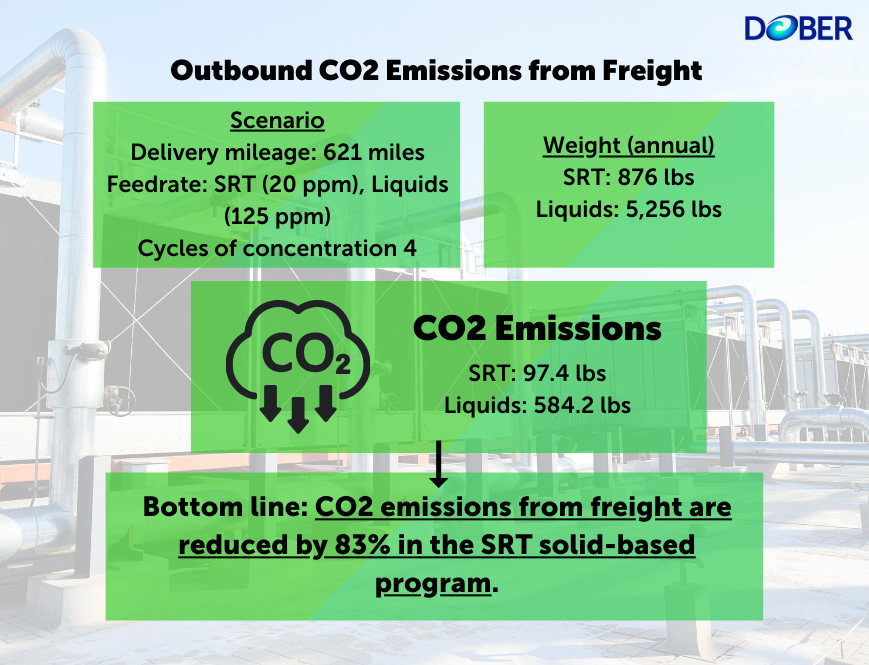

As mentioned in the introduction, we crunched some numbers to determine outbound CO2 (i.e., finished goods) associated with freight of Smart Release Technology solid chemistries versus that of liquids.

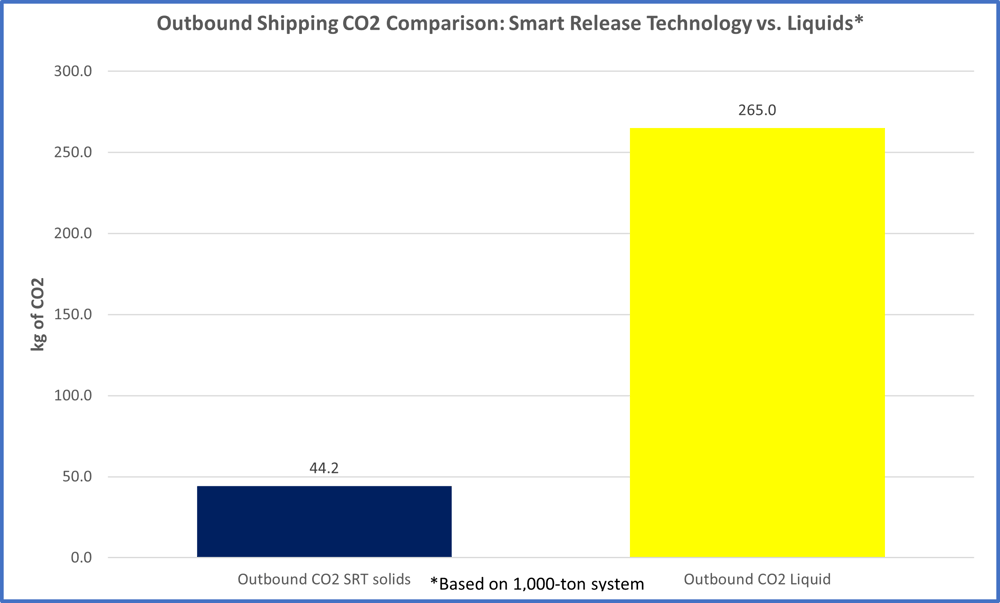

First, let's take a quick look at the numbers we assessed for a system with a 1,000-ton load and about 5.26 million gallons of blowdown per year. (CO2 per mile is set at 0.162 kg per short ton/mile, as per the "The Green Freight Handbook" from the Environmental Defense Fund.) For this example, the SRT solid-based program feedrate is set at 20 ppm and at 120 ppm for the liquid-based program.

Outbound CO2 Emissions

Now, let's take a look at outbound CO2, using a delivery mileage of 621 miles as an example.

Weight

- SRT: 876 pounds

- Liquid: 5,256 pounds

Total Outbound CO2

- SRT: 44.2 kg, 97.4 pounds

- Liquid: 265.0 kg, 584.2 pounds

Annual Outbound Co2

- Smart Release Technology: 44.2 kg

- Liquid: 265.0 kg

In other words, under these parameters, outbound CO2 associated with freight for Smart Release Technology solid chemistries is 83% lower than that of liquids.

Every cooling system is different. Furthermore, every cooling tower operator has his or her own priorities that can vary based on a wide range of factors.

For many operations, however — that is, not just cooling towers — sustainability is an important consideration. In fact, when it comes to choosing a service or products, and costs are similar between two products, many will consider the option they view to be more sustainable.

From a business perspective, being seen as a sustainable operation or having a reputation of sustainability can be a boon for your site.