SMART RELEASE TECHNOLOGY IS A TOTAL SOLID-FEED TREATMENT SYSTEM

Say goodbye to liquids, hello to Smart Release.

Anyone who has worked with liquid chemistries knows the challenges associated with liquids such as spills, pump failures, and deliveries. Solid cooling tower chemicals have been around since the 1970s in an attempt to overcome these challenges.

The truth is, anyone can turn a liquid into a solid. The challenge is in controlling the release of proper chemical levels over an extended period of time.

- With Smart Release Generation 1, 30-day, controlled-release chemistries solve this challenge for the cooling tower chemical industry.

- Now, with Smart Release Generation 2, enjoy complete control of your system, delivering chemicals only when is needed. You can also target larger applications.

SMART RELEASE TECHNOLOGY PRODUCTS

BIOCIDES

Preventing microbiological contamination requires a strong biocide treatment program. That is why Smart Release offers both oxidizing and non-oxidizing biocides.

The benefits of a solid biocide program are:

No drum or pail disposal

No spills or splashes

Designed for 30 days of

controlled-release

SCALE & CORROSION INHIBITORS

Born from the same science that controls the release of pharmaceutical drugs in your stomach, Smart Release scale and corrosion tablets give you peace of mind knowing that as long as water is flowing, your cooling tower is being protected.

Minimize maintenance costs (from pump failures)

Formulations protect in both low- and high-LSI applications

Designed for 30 days of controlled release

CHEMICAL FEED EQUIPMENT

Complete your solid-feed water treatment system with off-the-shelf, DIY systems or with customized, pre-built skids. Smart Release Generation 1 and Smart Release Generation 2 feeder systems are used to feed both scale and corrosion inhibitors and biocides. Options include:

Small, medium, large DIY feeders

Off-the-shelf, pre-built skids

Customized skids to fit unique systems

try our sizing calculator

Which Smart Release system is right for you?

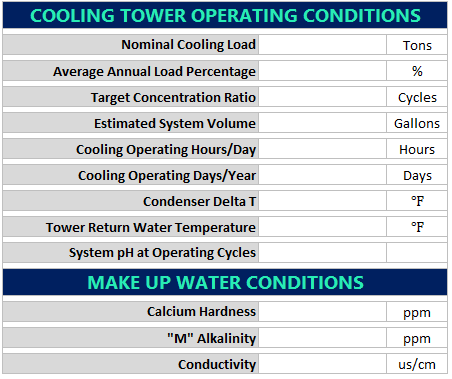

It's easy to find out. All you need is some basic information about your cooling tower (pictured at right) to fill out our sizing calculator app form. You'll receive a Smart Release recommendation that's tailored to you and your cooling tower's unique conditions.

Just like the Smart Release feeder systems, it doesn't get any easier than that.

Lower your carbon footprint with a safer solution

ELIMINATE DISCHARGE OF HARMFUL CHEMICALS

Unlike traditional liquid chemistries that require stabilizers to keep raw materials in solution, Smart Release contains at least 97% active as the salts. This eliminates the discharge of many harmful chemicals into the waterways.

LOWER CO2

Smart Release products are delivered in recyclable cardboard boxes and the highly active concentration reduces shipping weight, thus lowering CO2 emissions.

HOW SMART RELEASE TECHNOLOGY WORKS for your cooling tower water treatment program

AN ALTERNATIVE TO LIQUID COOLING TOWER CHEMICALS

Since our launch in 2007, thousands of locations throughout the world have switched to Smart Release Technology. Whether the sites switch because of the reliability of treatment (no chemical metering pumps), the ergonomics (no drums), or the simplicity, they all benefit from removing the often unsightly look of a liquid setup.

Learn more about some of the top reasons to make the switch to Smart Release Technology's solid-feed cooling tower water treatment solution.

Improve reliability and ergonomics by eliminating liquids.

Press the easy button and buy pre-built skids for small or large towers.

Smart Release uses the same chemistries you're used to but applied with solids.

We are a proud member of the Association of Water Technologies (AWT).

Start Using Smart Release Today